Product Description

Customized processing and packaging machine ratchet SMD carrier tape pin wheel semiconductor vibration plate parts

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | HangZhou, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Detailed Photos

Mask machine knurling wheel: It is processed into a rough blank by CNC turning, and then processed by precision 5-axis CNC, and then surface electroplating is completed.

Motor shaft copper sleeve: The material is H59 brass which is precision CNC turned, then 5-axis CNC milled, and finally electroplated for surface treatment.

Robot accessory bracket: Made of AL6061 aluminum alloy after 5-axis milling and then oxidized natural surface treatment.

Fine-tuning dial: It is used for scale adjustment of terminal machines and mechanical equipment. It is made of high-hardness and durable carbon steel, processed by CNC lathe and precision 5-axis CNC, and then electroplated on the surface.

Speech microphone: AL6063 aluminum alloy material is processed by CNC lathe and 5-axis CNC, and then oxidized gold on the surface. It is used in: KTV, schools, karaoke halls, stages, speeches and other public places.

Titanium alloy interface: Made of Tc4 titanium alloy material through precision CNC processing and 5-axis CNC processing. It is used in: equipment interfaces, mechanical interfaces, aviation plug interfaces, etc.

Company Profile

We are a manufacturer integrating industry and trade. We have more than 20 years of experience in production technology. We are located in HangZhou City, ZheJiang Province, China. We have advanced high-end professional production and processing technology, and are committed to innovative R&D and production. After years of market tempering and exploration, it has high-quality technical management personnel, experienced designers, R&D personnel and a perfect company management system.

CNC Trining Parts

5-axis CNC workshop

Our factory has a plant area of about 2,000 square CHINAMFG and masters core processing technologies. It has high-end precision production equipment: CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, die-casting equipment, etc.

2.5-dimensional detection equipment

Auxiliary production equipment: electroplating, anodizing, hard anodizing and surface treatment.

We have complete testing equipment: sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector and other conventional testing equipment.

If you are interested in our products, please contact me and I will provide the best price support and quality service.

Three-dimensional imager

I believe we will establish a good and long-term cooperation.

Welcome to send pictures and letters to discuss, thank you!

Product Parameters

We cooperate with many high-quality material suppliers, and the quality is very guaranteed. Please feel free to choose our materials. At the same time, supporting documents can be provided for all materials. Materials are available, such as aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, acrylic, etc.

Aluminum 6061/6063/7075; Iron 1215/45/1045; Stainless steel 303/304/316; Copper; Brass; Bronze (H59/H62/T2/H65); Plastic POM/PE/PSU/PA/PEEK, etc. can be based on Customer requirements.

surface treatment

For surface treatment, our suppliers have been working with us for many years. They have rich experience and are familiar with all the quality requirements of each other. The quality is stable and more guaranteed. Such as: heat treatment, spray painting, powder coating, blackening, silver/gold plating, electrolytic polishing, nitriding, phosphating, nickel/zinc/chromium/TiCN plating, anodizing, polishing, passivation, sandblasting, galvanizing, heat treatment , hardening, laser marking, etc. according to customer requirements.

Aluminum alloy surface oxidation

Dust-free electroless nickel plating on carbon steel surface

FAQ

Q1: Where can I get product & price information?

A1: Send us an inquiry e-mail, we will contact you once we received your mail.

Q2: How long will I get the sample?

A2: Depends on your specific items, within 3-7 days generally.

Q3: What kinds of information do you need for a quote?

A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.

Q4: What are the payment terms?

A4: We accept 50% as a payment deposit, when the goods are prepared, we shoot photos or videos for your check, and then you can

pay the balance. For small quantities, we accept Paypal, the commission will be added to the order. For big amounts, T/T is

preferred.

Q5: How to deliver the goods?

A5: We deliver the products by courier company.

Q6: Are you a trading company or factory?

A6: We are factory direct with 17 experienced engineers and more than 50 employees as well approximate 3,000m2 workshop area.

Q7: What shall we do if we don’t have drawings?

A7: Please send your sample to our factory, then we can copy and provide you better solutions. If send us pictures or drafts with

dimensions(Length, Height, Width), CAD or 3D file will be made for you.

Q8: Can we get some samples before mass production?

A8: Absolutely yes.

Q9: Will my drawings be safe after sending them to you?

A9: Yes, we will keep them well and won’t release them to the third party without your permission.

Q10: Is it possible to know the operation status of my products without visiting your company?

A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the

machining progress.

Q11: If you make poor quality goods, will you refund?

A11: In fact, we won’t take risks to produce poor-quality products. Meanwhile, we manufacture good quality products till you are

satisfied.

Packaging & Shipping

Packaging Details

1. Commercial packaging: 1pc/plastic bag + color box +carton + pallet;

2. Industrial packaging: (1). plastic tube + carton + pallet; (2). plastic bag + kraft paper + carton + pallet;

3. According to the requirement of customer.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Professional Service |

|---|---|

| Warranty: | 30 Days |

| Certification: | ISO9001, ISO, CE |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the impact of ratchet wheels on the overall safety of mechanical systems?

Ratchet wheels play a crucial role in enhancing the overall safety of mechanical systems in various applications. Their impact on safety can be summarized as follows:

- 1. Preventing Unintended Backdriving: One of the primary safety benefits of ratchet wheels is their ability to prevent unintended backdriving or reverse motion. When a pawl or catch mechanism engages with the teeth of the ratchet wheel, it locks the wheel in place, ensuring that the system does not move in the undesired direction. This feature is especially important in applications where maintaining a specific position or preventing sudden movement is critical for safety.

- 2. Controlled Motion: Ratchet wheels provide controlled and incremental motion, allowing users to make precise adjustments or movements. This controlled motion is essential in applications where precise positioning or controlled advancement is necessary for safety reasons, such as in medical devices, manufacturing equipment, or safety mechanisms.

- 3. Safety Interlocks: Ratchet wheels are often used in safety interlock systems where certain conditions must be met for a system to operate safely. For example, in industrial machinery, a ratchet wheel and pawl mechanism can be part of an interlock system that ensures equipment remains stationary until specific safety conditions are met, reducing the risk of accidents.

- 4. Load Handling and Securement: In load handling and securement applications, such as winches and tie-down straps, ratchet wheels help maintain tension and prevent slack. This contributes to the safe transportation of loads, reducing the risk of load shifts or accidents during transit.

- 5. Emergency Stop Systems: Ratchet wheels are employed in emergency stop systems to ensure that once the system is activated, it remains in a safe state until intentionally reset. This safety feature is vital in machinery and equipment where rapid shutdown is necessary to prevent hazards.

- 6. Reliability and Predictability: Ratchet wheels offer reliability and predictability in their operation. Users can apply force or torque in the desired direction with confidence, knowing that the ratchet mechanism will engage and prevent unexpected movement. This predictability enhances the overall safety of the system.

- 7. Versatility in Safety Applications: Ratchet wheels find application in a wide range of safety-critical systems, including vehicle handbrakes, safety gates, medical devices, and more. Their ability to provide controlled and secure motion makes them versatile components in various safety applications.

In summary, ratchet wheels contribute significantly to the safety of mechanical systems by preventing unintended movement, providing controlled motion, enabling safety interlocks, and enhancing reliability. Their presence in safety-critical applications helps reduce the risk of accidents and ensures that systems operate safely and predictably.

What are the signs that indicate a need for ratchet wheel replacement or maintenance, and how can they be diagnosed?

Recognizing the signs that indicate the need for ratchet wheel replacement or maintenance is crucial for ensuring the reliability and safety of mechanical systems. Here are common signs and how to diagnose them:

- 1. Excessive Wear: Check the ratchet wheel’s teeth for signs of excessive wear or rounding. If the teeth are visibly worn down, it’s an indication that the ratchet wheel may not engage properly and should be replaced.

- 2. Irregular Tooth Engagement: During operation, if you notice irregular engagement of the ratchet wheel with the pawl or catch, it may indicate misalignment, damage, or wear. Investigate and address the issue to prevent further damage.

- 3. Slippage: If the ratchet wheel slips when subjected to a load within its specified capacity, it’s a clear sign of wear or damage. This can compromise the safety and reliability of the system and warrants immediate attention.

- 4. Unintended Movement: In applications where a ratchet wheel is used to prevent unintended movement or reverse motion, any unexpected movement suggests a problem. This may be due to wear, damage, or a malfunctioning pawl mechanism.

- 5. Noise and Vibration: Unusual noises, such as grinding or rattling, or excessive vibration during ratchet wheel operation can indicate issues with teeth engagement, misalignment, or worn components.

- 6. Difficulty in Turning: If the ratchet wheel becomes difficult to turn, it may be due to increased friction caused by wear or contamination. This can lead to inefficient operation and should be addressed.

- 7. Visual Inspection: Regularly inspect the ratchet wheel for visible damage, cracks, or deformities. Any visible defects should be taken as a sign that maintenance or replacement is needed.

- 8. Pawl or Catch Condition: Examine the condition of the pawl or catch that interacts with the ratchet wheel. Signs of wear or damage on the pawl can affect the engagement and should be addressed.

- 9. Reduced Efficiency: If the ratchet wheel system is no longer operating with the same level of precision and efficiency as before, it may be an indication of wear or misalignment.

- 10. Routine Maintenance Schedule: Implement a routine maintenance schedule for ratchet wheel systems. Regular maintenance can help identify early signs of wear or issues before they become critical.

- 11. Load Testing: Conduct load testing to ensure that the ratchet wheel can handle its specified load capacity without slipping or exhibiting signs of stress. Any failures during load testing should prompt maintenance or replacement.

Diagnosing the need for ratchet wheel replacement or maintenance often involves a combination of visual inspection, functional testing, and a good understanding of the system’s expected performance. Addressing issues promptly can prevent failures and improve the safety and reliability of mechanical systems.

What are the different types and sizes of ratchet wheels available in the market?

Ratchet wheels come in various types and sizes to accommodate a wide range of applications. The choice of ratchet wheel type and size depends on factors such as load capacity, space constraints, and the specific requirements of the mechanical system. Here are some common types and sizes of ratchet wheels available in the market:

- 1. Standard Ratchet Wheels: These are the most common type of ratchet wheels, featuring a set of angled teeth that engage with a pawl or catch mechanism. Standard ratchet wheels are available in a variety of sizes, typically ranging from small diameters (e.g., a few inches) to larger ones (e.g., a foot or more) to accommodate different applications.

- 2. Fine-Tooth Ratchet Wheels: Fine-tooth ratchet wheels have smaller and more closely spaced teeth compared to standard ratchet wheels. This design allows for finer control and incremental movement in applications where precision is critical. Fine-tooth ratchet wheels are often used in instruments, delicate machinery, and applications requiring precise adjustments.

- 3. Large Diameter Ratchet Wheels: In heavy-duty applications such as industrial machinery and material handling equipment, large diameter ratchet wheels are employed to handle substantial loads. These ratchet wheels can have diameters exceeding a foot or more, providing the necessary strength and engagement surface for robust performance.

- 4. Miniature Ratchet Wheels: Miniature ratchet wheels are designed for compact and space-restricted applications. They are smaller in size, typically measuring fractions of an inch in diameter. These miniature ratchet wheels are commonly used in electronics, medical devices, and precision equipment.

- 5. Custom Ratchet Wheels: For specialized applications or when off-the-shelf ratchet wheels do not meet specific requirements, custom ratchet wheels can be manufactured. Customization allows for tailoring the size, tooth profile, and material to suit unique applications and load capacities.

- 6. Corrosion-Resistant Ratchet Wheels: In environments where corrosion is a concern, ratchet wheels may be available with special coatings or materials that enhance their resistance to rust and corrosion. These ratchet wheels are suitable for marine, outdoor, or humid conditions.

The availability of ratchet wheel types and sizes in the market ensures that industries and applications of all scales can find the appropriate ratchet wheel to meet their specific needs. Whether it’s for heavy-duty machinery or precision instruments, ratchet wheels come in various configurations to support a wide range of mechanical systems.

editor by CX 2023-12-27

China best Non-Standard Custom Tape Carrier Pin Wheel Packaging Machine Ratchet Detection Machine Fiber Optic Machine Indexing Wheel

Product Description

Non-Standard Custom Tape Carrier Pin Wheel Packaging Machine Ratchet Detection Machine Fiber Optic Machine InHangZhou Wheel

We are a manufacturer integrating industry and trade. We have more than 20 years of experience in production technology. We are located in HangZhou City, ZheJiang Province, China. We have advanced high-end professional production and processing technology, and are committed to innovative R&D and production. After years of market tempering and exploration, it has high-quality technical management personnel, experienced designers, R&D personnel and a perfect company management system.

The factory has a workshop area of 2,000 square CHINAMFG and masters high-end production core technology. Has advanced precision production equipment: CNC lathes, five-axis CNC, four-axis CNC, auxiliary production equipment, electroplating, anodizing, hard anodizing and surface treatment.

Has complete testing equipment: the introduction of advanced three-dimensional, advanced two-dimensional, hardness, height gauge, projector and some conventional testing equipment.

If you are interested in our products, please contact me, I will provide the best price support and quality service.

I believe we will establish a good and long-term cooperation.

Welcome to map and email to negotiate, thank you!

| After-sales Service: | Professional Service |

|---|---|

| Warranty: | 30 Days |

| Certification: | ISO9001, ISO, CE |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can ratchet wheels be customized for specific uses or integrated into different systems?

Yes, ratchet wheels can be customized for specific uses and seamlessly integrated into various mechanical systems. Customization allows for tailoring ratchet wheels to meet the unique requirements of specific applications. Here are ways in which ratchet wheels can be customized and integrated:

- 1. Custom Tooth Profile: Ratchet wheels can be designed with a specific tooth profile to match the desired level of control and movement. Custom tooth spacing and sizes can be created to achieve precise incremental motion or accommodate varying load capacities.

- 2. Material Selection: Depending on the application’s demands, ratchet wheels can be manufactured from different materials, including various types of metals such as steel, stainless steel, or alloys. Specialized coatings can also be applied for enhanced durability and corrosion resistance.

- 3. Size and Diameter: The size and diameter of the ratchet wheel can be customized to fit within the available space of the mechanical system. This ensures a proper fit without clearance issues or interference with other components.

- 4. Load Capacity: Custom ratchet wheels can be designed to handle specific load capacities, making them suitable for both light-duty and heavy-duty applications. Reinforced designs with larger teeth and diameters can support heavier loads.

- 5. Pawl and Catch Mechanism: The design of the pawl or catch mechanism can be tailored to ensure optimal engagement and disengagement with the custom ratchet wheel. This customization ensures reliable operation in the intended application.

- 6. Precision Requirements: For applications demanding precise control and adjustments, fine-tooth custom ratchet wheels can be created to provide finer incremental movement and enhanced accuracy.

- 7. Regulatory Compliance: Custom ratchet wheels can be designed to meet specific industry standards and safety regulations, ensuring compliance with applicable requirements.

- 8. Integration into Systems: Ratchet wheels can be seamlessly integrated into various systems, including hand tools, winches, tie-down mechanisms, conveyor systems, and more. Their unidirectional and locking capabilities make them valuable components in many applications.

Customized ratchet wheels are often used in specialized industries and applications where standard off-the-shelf components may not fully meet the unique demands. Manufacturers and engineers work closely to design and produce custom ratchet wheels that precisely match the specifications and requirements of the intended use, contributing to the efficiency and reliability of the mechanical systems they are part of.

How do ratchet wheels contribute to the precision and repeatability of certain applications?

Ratchet wheels play a pivotal role in enhancing precision and repeatability in various applications by providing controlled and incremental motion. Their contributions to precision and repeatability can be explained as follows:

- 1. Controlled Movement: Ratchet wheels are designed to engage with pawls or catches in a way that allows them to move in only one direction while preventing backward movement. This controlled movement ensures that adjustments, increments, or positioning occur with a high degree of accuracy.

- 2. Incremental Adjustments: In applications where precision is crucial, such as in manufacturing, assembly, or calibration equipment, ratchet wheels enable users to make incremental adjustments or movements. This precision allows for fine-tuning and achieving the exact desired outcome.

- 3. Consistency and Repeatability: Ratchet mechanisms, including ratchet wheels, provide a consistent and repeatable motion. Users can reliably achieve the same result repeatedly, ensuring product consistency in manufacturing or consistent positioning in various tasks.

- 4. Safety and Position Locking: Ratchet wheels are commonly used in safety-critical applications where specific positions must be securely locked. This locking feature not only enhances safety but also ensures that a particular setting or position remains precise and repeatable.

- 5. Indexing and Positioning: In applications like indexing tables or machinery requiring precise indexing or positioning, ratchet wheels enable accurate and repeatable alignment of components or workpieces. This is essential for processes such as drilling, milling, or assembly.

- 6. Calibration and Measurement: Ratchet mechanisms are utilized in calibration equipment to allow for precise adjustments of measuring instruments. This contributes to the accuracy and repeatability of measurements, which is critical in scientific, laboratory, and metrology applications.

- 7. Safety Interlocks: Ratchet wheels are often part of safety interlock systems that require specific conditions to be met before certain operations can proceed. This ensures that critical safety protocols are consistently followed.

- 8. Reliability in Emergency Systems: Ratchet mechanisms are incorporated into emergency systems where reliability and repeatability are paramount. For example, emergency stop systems rely on the repeatability of ratchet wheels to ensure consistent and immediate shutdown of machinery.

- 9. Reducing Human Error: In applications where human operators are involved, ratchet wheels help reduce the likelihood of errors. The controlled and incremental motion they provide minimizes the risk of overshooting or undershooting desired settings.

In summary, ratchet wheels contribute to precision and repeatability by enabling controlled and incremental motion, ensuring consistent and repeatable results, and enhancing safety in various applications across industries.

Can you describe the factors to consider when selecting ratchet wheels for specific applications?

When selecting ratchet wheels for specific applications, several important factors should be taken into consideration to ensure optimal performance and reliability. These factors include:

- 1. Load Capacity: Determine the maximum load or force the ratchet wheel will need to handle. Choose a ratchet wheel with the appropriate load capacity to ensure safe and efficient operation. Larger and more robust ratchet wheels are suitable for heavy-duty applications.

- 2. Space Constraints: Consider the available space within the mechanical system where the ratchet wheel will be installed. Ensure that the selected ratchet wheel size fits within the allocated space without interference or clearance issues.

- 3. Tooth Profile: The tooth profile of the ratchet wheel should match the application’s requirements. Standard ratchet wheels have angled teeth, while fine-tooth ratchet wheels offer finer control. Select the tooth profile that suits the desired level of precision and movement control.

- 4. Material: Choose a ratchet wheel material that is compatible with the application’s environment and demands. Common materials include hardened steel or alloy metals for durability. In corrosive environments, opt for corrosion-resistant coatings or materials.

- 5. Pawl Compatibility: Ensure that the selected ratchet wheel is compatible with the pawl or catch mechanism used in the application. The pawl should effectively engage and disengage with the ratchet wheel’s teeth for reliable operation.

- 6. Precision Requirements: Consider the level of precision required in the application. Fine-tooth ratchet wheels are suitable for applications demanding precise adjustments, while standard ratchet wheels offer a balance of control and strength.

- 7. Operating Conditions: Evaluate the operating conditions, including temperature extremes, humidity, and exposure to chemicals or contaminants. Select ratchet wheels that can withstand these conditions without degradation.

- 8. Customization: For specialized applications or unique requirements, consider the option of custom-designed ratchet wheels. Customization allows for tailoring the ratchet wheel’s size, tooth profile, and material to meet specific needs.

- 9. Maintenance: Assess the ease of maintenance and lubrication requirements. Some ratchet wheels may need periodic cleaning and lubrication to ensure smooth and reliable operation.

- 10. Regulatory Compliance: In some industries, specific standards and regulations may govern the choice of components. Ensure that the selected ratchet wheel complies with relevant industry standards and safety regulations.

By carefully considering these factors, you can select the most suitable ratchet wheel for your specific application, promoting efficient and reliable performance while minimizing the risk of issues or failures.

editor by CX 2023-11-27

China made in China – replacement parts – in Goiania Brazil Discount Metal Cutting Hot Sale CNC Plasma Cutter Machine with Thc Controller with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 different branches. For far more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

China price reduction metal chopping very hot sale cnc plasma cutter equipment with THC controller

We also have EPT types, this kind of as FMP1325, FMP1530, FMP2030,FMP2040 and so forth

Aside from, we also have gantry cnc flame plasma slicing machine.

Characteristics:

1.Welded thick-walled metal structure, right after specific treatment, no distortion for the complete composition high precision, and prolonged provider lifestyle time.

2. Chopping program use ZheJiang starfire system/ Begin system/ FLMC-2300A or D EPT technique

Geared up with computerized height controller ( THC controller), which can in accordance to your substance planeness,

cutting head can routinely steady, and fa EPT alter.

three. ZheJiang HIWIN linesr rail, make sure vertical section, a lot more precision.

four. Appropriate software: Artcam/ Fstcam/ / TyArtcam/ Beihang Haier and so on.

5. In allusion to the reducing of 3-dimensional LED marketing term, steel plate of sulciform figures and foundation plate,

chopping precision reach to excellent indicators.

6. High configuration of numerical handle system, automatic striking the arc, stable with dependable overall performance.

Techncial specification:

| Model | FMP1325 | FMP1530 | FMP2030 | FMP2040 | FMP2060 |

| Table mattress dimension (mm) | 2500*1300mm | 3000mmx1500mm | 3000mmx2000mm | 4000mmx2000mm | 6000*2000mm |

| Controller system | Starfire / Start/ FLMC-2300A / D EPT optional | ||||

| Reducing speed | 8-15m/min | ||||

| Top handle | arc voltage torch peak controller | ||||

| Electrical power provide | Chiense LGK Seires American Hypertherm Series |

||||

| Plasma cutter head | Chinese palsma cutter head American cutter head |

||||

| Motor | Step motor / Servo Mootr | ||||

| X,Y,Z axis information rail | ZheJiang HIWIN guide rail | ||||

| X,Y,Z axis transmission | ZheJiang TBI Ball screw | ||||

| Repeat positioning accuracy | ±0.05mm | ||||

| Approach precision | ±0.35mm | ||||

| Transmission model | Gear rack push | ||||

| Functioning Voltage | 380V/3P/50-60HZ | ||||

| Table-board | Steel blade noticed tooth mesa | ||||

| Support application | Drawing software program–CAD Nesting software program–Fastcam software Cutting path file–artcam, type3 and many others |

||||

| Functioning mode | Non-make contact with arc | ||||

| Non-contact arc | USB | ||||

Principal configuration:

# Starfire management technique with THC

The numerical management program with large disposes, plasma device devoted program , the overall performance is steady.

#Flame plasma cutter head with THC

LGK sequence plasma cutter head

Optional American Hypertherm plasma source

#Plamsa source

Mo EPT renowned brand of China, max cutting thickness 35mm.

Optional American Hypertherm plasma source

#HIWIN sq. gudie rail

Substantial precision and considerably less wear , with planet well-known ZheJiang hiwin self-lubricating sliding block

#Noticed tooth mesa table and Roll ball

Tooth mesa desk, strong fixation materia EPT capability roll ball simple feeding supplies

Apps Business :

Broadly employed in the industries as aerospace, agricultural machinery, construction machinery, railway manufacturing, elevator manufacturing, special development automobile, instrument production, oil machinery production, foods equipment, adorned advertizing, foreign processing serviceand all sorts industries relevant to mechanical production.

Slicing materials:

For iron, aluminum, galvanized sheet, white sheet, titanium plate and EPT steel plates.

Processing shel EPT of equipment and electronic items, advertising indications, crafts, iron backyard, car manufacture, boat building, electrical equipment, board cutting.

Samples of plasma cutting equipment

EPT connected plasma chopping machine for your reference

# Hefty obligation cnc plasma slicing device

# Economic kind cnc plasma chopping equipment

# Gantry cnc plasma reducing machine

# Flame plasma chopping equipment

# cnc plasma slicing equipment with smoke admirer

Firm Information

FIRMCNC Group located in HangZhou,ZheJiang PR, Launched in 2003. Chief of cnc router equipment manufacture.

We are an all-round enterprice,which is thorough in R&D, manufacture, and revenue on cnc router appliances.

This is our plasma machine workshop

Our Providers

1. 24 hour Technical help by phone, e-mail or MSN about the clock.

two. Helpful English model handbook and operation video CD disk.

three.7-15 doing work days right after down payment or entire payment.

4. Equipment will be adjusted ahead of it is delivered procedure disk/CD was integrated.

five. Our technician can give you distant guidebook on the internet (Skype or MSN) if you have any issue.

6. Engineers offered to support machinery abroad, vendor and customer talk about the expenses.

Bundle:

1)Foam and wrapping film on the surface area of the device inside. Rain-proof, Du EPT evidence.

two)Standard export plywood circumstance. Upwards, moistureproof transport marks. Basic safety certain.

three) fumigation-totally free

four)With shipping and delivery mark if you like.

five)Outside the house: Marked packing dimension, product, bodyweight and EPT info

FAQ:

one.Can you suggest a plasma chopping equipment?

Of course, In purchase to give you a suitable plasma cutting equipment, p EPT explain to me your operating area ? processing materia EPT ?

Then excellent ideal device will be suggest.

2.Do you have procedure guide and functioning movie?

Sure, soon after we verify buy, procedure manual will be deliver to you.

three.Does your organization can processing my samples?

Of course, we can

four.If I bought equipment, but don’t know how to procedure, what I can do?

Our engineer will educate you how to operation the machine by way of guide, online video contact or e mail, I still aso will help you .

5.How am I going to perform on service parts on the equipment? Illustration what if components want to be changed?

In the course of the time period of warranty, we will totally free ship broken parts to you, soon after guarantee, we can offer you agent cost for parts.

normally for all components can perfect working 1 calendar year with out any damaged .

six.Does your engineer do aftersale support at abroad? how considerably price?

Indeed, our technician can do education and soon after sale provider at yoru manufacturing facility, you only want to pay out the round air tickets co EPT and accommodation for technician.

HangZhou Organization CNC Equipment CO.,LTD

Tel: 0086-571-69986330 Fax : 0086-571-69986330

Internet site: http://firmcnc.en.made-in-china.com ,

The use of authentic equipment manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our organization and the shown substitution parts contained herein are not sponsored, approved, or made by the OEM.

1325 made in China – replacement parts – in Samara Russian Federation 1530 1560 2040 2030 Huyuan Cheap Portable CNC Steel Tube Plasma Cutting Cutters Machine Metal 8 15 18 20 30mm 63 100 120A 160A 200A with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For a lot more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Product Description

Functions of plasma metallic cutting machine

one)The beam utilizes gentle structural design,with very good rigidity framework, light weight and modest movement inertia.

two)The gantry composition, Y axis utilized dual-motor dual-driven method, X, Y, Z axis all use twin-straight rail that make the machine driving smoothly with large-precision.

three)Xihu (We EPT Lake) Dis.g at reducing three dimension LED character, trough metallic pane EPT and flooring reducing,the accuracy can achieve great indicators. Equipped with EPT advertise products (blister device, engraving equipment),forming the promoting phrase processing pipeline. Fully solve the conventional guide processing techniques. Enhance the performance of many instances.

four)Cutting mouth is small, tidy,and avoid a second dressing processing.

5) It can use to iron sheet the aluminium sheet, the galvanized sheet, hundred steel plates, steel plates and so on.

6)Large reducing pace, higher precision, and reduced value.

seven)The numerical manage method disposes substantial, the automated placing arc, the functionality is steady.

8)Assist Wentai, Astronautics Haire, ARTCAM softwares, Type3 make normal G code way document, also can alter software program.

Product Parameter

| Plasna Reducing Equipment detai EPT configurations | |||

| Working size | 1300*2500mm/1500*300mm/1500*4000mm/1500*6000mm /2000*3000mm/2000*4000mm/2000*6000mm |

||

| Cutting thickness on aluminum | Power(A) | Highest reducing thickness | Suggested cutting thickness |

| 63A | 15mm | ≤12mm | |

| 100A | 25mm | ≤20mm | |

| 120A | 30mm | ≤25mm | |

| Plasma source manufacturer | China Xihu (We EPT Lake) Dis./Usa Hypertherm | ||

| X,Y, Z repeat positioning precision | ±0.05mm | ||

| Process precision | ±0.35mm | ||

| Cutting speed | 10-15m/min | ||

| X,Y axis transmission | ZheJiang Hiwin information rail+rack gear | ||

| Z axis transmission | ZheJiang Hiwin guide rail+TBI ball screw | ||

| Control system | China ZheJiang Startfire manage system | ||

| Motor and motorists | Stepper, Leadshine-Stepper,YASKAWA or Pansonic | ||

| Cutting speed | 1-50mm | ||

| File transmission form | USB Interface | ||

| Instruction format | G code | ||

| Table-board | Steel blade saw tooth mesa | ||

| Input voltage | 3 section,220v/380v±10% | ||

| Optional component | Rotary/Flame chopping head | ||

Product Configuration

Cutting Sample

Factory InfoHangZhou Vmade CNC Device Co.,Ltd was recognized in 2571. Situated in large-tech zone, HangZhou Town, ZheJiang Province of China. It is a specialist group which specialised in Optic, Electric power, Mechanics, and R&D subject. Vmade keep sensitive and attentive attitude on every single action and often hold to discover the mo EPT sophisticated technologies and produce far more humanized items to all our buyers. These several years, Vmade has sold their products to all over the planet. This sort of as United states of america, Canada, Brazil, Russia, England, Australia, a lot more than 60 international locations and do OEM services to far more than 15 dealers and distributors. Vmade is warmly welcomed by consumers with their repeatedly enthusiasm, Frist-Course ahead of/soon after sales service, efficient reaction and the best machine quality.The name of Vmade originate from mo EPT of the buyers’ expectation. “V”, signifies the VIP design and creation which specifically custom-made to every single consumer “made”, means we use hundred percentage of our attention to target on every get, finalized all clients’ entru EPT with excellent items which are elaborate made.Vmade CNC, maintain innovation, with higher enthusiasm, to offer best project for

each and every shopper. Welcome be part of Vmade, we will never allow you down!

Successful Project

Certification

RFQ

1)How can I can get the be EPT cnc equipment for me?You can notify us your operating substance, detail perform by picture or vedio so that we can decide whether our device can satisfy your require or not.Then we can give you the be EPT model.

2)This is the fir EPT time I use this type of machine,is it simple to work?

We will ship you handbook and guide vedio in English, it can instruct you how to function the device. If you still can not learn how to use it,we can help you by Teamviewer on the internet aid computer software. Or we can speak by telephone,e mail or EPT speak to techniques.

three)If the machine has difficulty in my area,how could I do?

We could send free of charge areas to you in guarantee period if machines have any issue underneath “standard use”

4)This design is not appropriate for me,do you have much more model acailable?

Indeed, we can provide several designs. this kind of as advertising cnc router, metal cnc router, wood cnc router, stone cnc router and so on. Replacement of some part dependent on your require. The earlier mentioned are mo EPT popular. If it can not meet your prerequisite, then tell us.We have the capacity to make specially in accordance your prerequisite!

five)How about the paperwork soon after cargo of cnc equipment?

For standard equipment, it would be 7-ten times For non-normal machines and personalized equipment in accordance to clientele specific requirements, it would be 15 days.

six)Do you organize shipment for the equipment?

Indeed, pricey esteemed customers, for FOB or CIF cost, we will prepare cargo for you. For EXW price tag, clients want to arrange shipment by themselves or their brokers.

7)How is the packing of cnc equipment?

Water-proof plastic movie package with foam safety in each and every corner

Sound Seaworthy Wood Box Bundle with Steel Belt

Preserve place as considerably as attainable for container loading

The use of original equipment manufacturer’s (OEM) element quantities or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our company and the listed substitution elements contained herein are not sponsored, accredited, or created by the OEM.

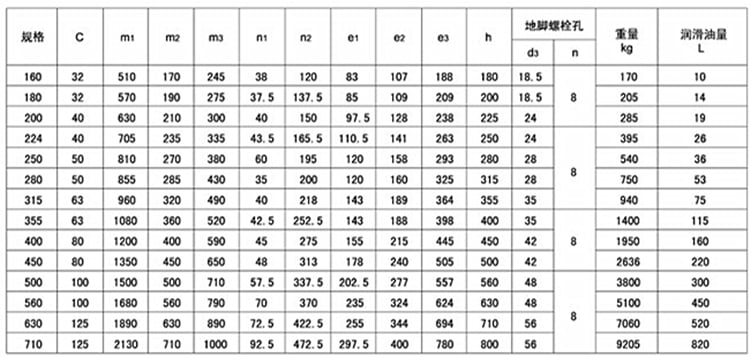

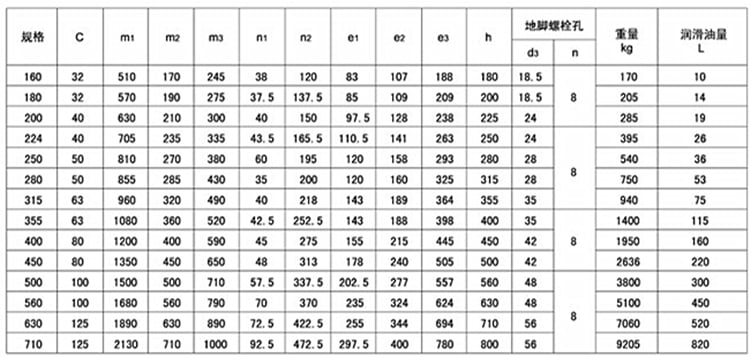

China manufacturer & factory supplier for china in Karaj Iran supplier ZSY 630 710 hollow solid vertical to horizontal shaft mounted gearbox for belt drive bending machine With high quality best price & service

engineering class chains & precision roller chains. Single strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains.At any time-Energy Group CO., LTD. IS Professional IN Generating ALL Sorts OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Pace REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Automobile GEARBOXES, PTO Travel SHAFTS, Special REDUCER & Relevant Gear Components AND OTHER Related Goods, SPROCKETS, HYDRAULIC System, VACCUM PUMPS, FLUID COUPLING, Equipment RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Lower BACKLASH WORM REDUCERS AND pto shaft, agricultural gearboxes SO ON.

Overview

Fast Particulars

- Relevant Industries:

-

Production Plant

- Pole:

-

One/Two/Three Stage Velocity Reducer

- Ratio:

-

one.twenty five-a hundred

- Housing Content:

-

Cast Iron

- Doing work temperature:

-

-forty~45℃

- Software:

-

mining, chemical industry,metal metallurgy,lifting transpor and ect.

- Approach:

-

Carburizing, Nitriding , Grinding

- Performance:

-

94%~98%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Environmentally friendly,Grey,Crimson

- Type:

-

Shut up of shear pin which will shear in 50 % if the put into action is subject matter to enough resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The pushed conclude yoke is really two parts with a shear pin or bolt that holds the two parts as one throughout procedure. Must the products face a sudden end the pin will consider the shock and “shear off” protecting against any driveline damage.

vertical to horizontal shaft mounted gearbox for belt bending device

Provide Capacity

- Offer Ability:

- 3000 Established/Sets per 12 months vertical to horizontal shaft mounted gearbox for belt push bend

Packaging & Delivery

- Packaging Particulars

- sea deserving picket scenario for ZSY 630 710 hollow reliable vertical to horizontal shaft mounted gearbox for belt generate bending machine

- Port

- Qingdao

-

Direct Time

: -

Quantity(Luggage) 1 – twenty >20 Est. Time(times) 20 To be negotiated

On the internet Customization

Merchandise Description

Z Series Helical Equipment Reducer Gearbox

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical equipment reducer

D (DBY and DCY) series hard tooth surface cone equipment reducer

EPG——industrial gearbox producers

Chinese electrical motor pace reducer is widely used in mining machinery, chemical sector,steel metallurgy, gentle market,environmental defense, paper generating, printing, lifting transportation, food market and so on.

Main Series Product: R collection helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B collection gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical equipment reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, and so forth. Meanwhile, map sample processing enterprise can be carried out.

Function:

-

Applicable to the metallurgical,electricity technology,h2o remedy,design,chemical,paper,

textiles,drugs,foodstuff and other industries.

-

The transmission performance of solitary-phase can achieve up to ninety eight%, two-phase can achieve ninety six%, three-stage can achieve ninety four%.

-

The gear processed by Carburizing & Grinding with large precision.

-

Higher precision gear, regular transmission, big load capability

-

Prolonged service existence.

- One particular Two Three Stage Pace Reducer

Specification

ZSY 630 710 hollow strong vertical to horizontalDressing grinding wheels leaves a microscopic floor “thread” which, beneath the proper problems, can transfer to the seal journal and produce a leak path. shaft mounted gearbox for belt drive bending machine:

(remember to contact us for much more kinds & design)

Mounting Diamensions

Specific Parameters:

(remember to get in touch with us for far more kinds & product)

Model variety:

Closely utilizing the best reduction ratio.

Reduction ratio = servo motor pace / reducer output shaft velocity

Torque calculation: Torque calculation is extremely essential for the daily life of reducer, and spend attention to whether the highest torque price (TP) of acceleration exceeds the optimum load torque of the reducer.

The applicable electricity is usually the relevant energy of the servo types on the market place, the applicability of the reducer is quite substantial, the doing work coefficient can be maintained over 1.2, but the option can also be primarily based on their personal demands to choose. ZSY 630 710 hollow reliable vertical to horizontal shaft mounted gearbox for belt generate bending equipment.

| Driven equipment | |||

| Squander drinking water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking gear,blended longitudinal and rotary rakes,pre-thickeners,screw pumps,h2o turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping gadgets, carterpillar travelling gears, bucket wheel excavators as choose up, bucket wheel excavator for primitive content, cutter head, traversing gears |

| Chemical sector | Plate bending equipment, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal functioning mills | plate tilters, ingot pushers, winding devices, cooling mattress transfer frames, roller straigheners, desk continuous intermittent, roller tables reversing tube mills, shears constant, casting motorists, reversing blooming mills |

| Steel doing work mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower supporters, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar creation | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing devices, sugar beet cutter |

| Paper devices | Pulper drives | Cableways | Content ropeways, ongoing ropeway |

| Cement business | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

- one. Big Volecity- Reducing Ratio:Ratio of single-stage speed-decreasing is 1/eleven-1/87 Ratio of double phase speed-lowering is 1/112-1/5133Ratio of a few-stage pace-decreasing is 1/2057-1/446571more-phases can be mixed according to the necessity.

-

2. High driving efficiency:Because of to adopting rolling engagement in falling-in portion, the driving effectiveness can achieve earlier mentioned 90%.

-

3. Small in size, light fat: with compacted composition,tiny dimension and gentle bodyweight. Thanks to adopting the theory of earth driving so that the input and output shaft in the very same axis which will integrated with the motor.

-

four. Long support life: Has excellent resistance to abrasion due to the fact the main driving partaking elements are manufactured of bearing steel and implementing rolling friction.

-

5. Stable managing: for most driving process, we adopt multi-enamel slipping-in. Then the managing will be stable with minimal sounds.

-

6. Convenient dismounting:sensible structure and design.

-

seven. Strong overloading capability,anti-compact,suitable for frequently commence and double-side rotation.

Technology

China Speed Gear Reducer is a mechanical transmission in many fields of the countrywide economic climate. The merchandise categories protected by the sector contain all varieties of equipment reducer, planetary gear reducer and worm gearbox, as well as different specific transmission products such as velocity rising device, pace control Units, like different types of adaptable transmission devices, this sort of as compound transmission. Merchandise and providers in the area of metallurgy, nonferrous metals, coal, developing components, ships, water conservancy, electric power, construction machinery and petrochemical industries.

Chinese gearbox sector has a heritage of virtually 40 several years. In all fields of national financial system and nationwide protection sector, gearbox goods have a vast variety of apps. Foods light-weight market, electric equipment, construction equipment, metallurgy equipment, cement machinery, environmental protection equipment, digital appliances, highway design machinery, drinking water conservancy machinery, chemical machinery, mining machinery, conveyor equipment, developing materials machinery, rubber equipment, petroleum machinery and other industries have strong desire of Reducer merchandise. ZSY 630 710 hollow reliable vertical to horizontal shaft mounted gearbox for belt generate bending equipment.

Packaging & Transport

Firm Information

Established in 1995 , HangZhou At any time-Electricity Machinery is a expert manufacturer and exporter that is anxious with the design, advancement and manufacturing of Gearbox Pace Reducer. We are found in HangZhou of ZheJiang Province, with hassle-free transportation access. With our own brand “EPG”, all of our products comply with worldwide good quality requirements and are tremendously appreciated in a variety of different marketplaces throughout the globe.

Our business possesses total machining heart, lathe, gear shaping device, equipment milling equipment, gear grinding device and assembling lines. Our properly-equipped services and exceptional top quality handle throughout all phases of generation allows us to guarantee total client fulfillment.

In addition to, In 2005,we attained ISO9001 certification. As a outcome of our large good quality items and outstanding consumer service, we have gained a global revenue network reaching South The united states, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other nations around the world and areas.

With prosperous export expertise, large good quality products, competitive charges, great service and in-time supply, we specific that we can meet all of your need and exceed your expectations. Our feature is vivid with new cooperative associations with businesses from all in excess of the globe. We appear ahead to speaking with you to future discuss how we can be of service to you.

FAQ

1.Q:Are you the manufacturing unit or investing company?

A:We are the specialist Manufacturing unit with over 24 several years of expertise.

2.Q:Can you customize in accordance to our demands?

A:Sure, we can design and style nonstandard goods in accordance to customer’s drawing and sample.

3.Q:How lengthy is the shipping date?

A:ten-twenty working days.

four.Q:Where is your manufacturing facility?

A:We are in HangZhou of ZheJiang Province, you can get listed here by higher pace prepare or fly to Jinan.

Welcome to check out us!

Candy wholesaler made in China – replacement parts – in Maracay Venezuela Press Machine for Sale with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 diverse branches. For far more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Rotary pill machine have ZP-5, ZP-7, ZP-9 and EPT designs, in line with GMP requirements, tableting chamber completely different transmission mechanism, and material speak to components are produced of stainless steel or particular surface remedy, non-harmful corrosion-resistant, compression chamber with a clear plexiglass shut to prevent contamination. The complete floor is smooth, simple to deal with. Perform rotary tableting was compressed into tablets (the stress inside of the unit range), and the volume of powder that contains (a hundred mesh or far more) of not more than ten% suppression of granular supplies, suited for urgent spherical tablets of 4 to twelve mm . Small rotary tablet equipment is based mostly on the generation of automated rotation steady pill pill push device miniaturization, it is mainly utilised to study the procedure of the pharmaceutical, chemical, foodstuff, electronics and EPT industrial sectors, to verify whether or not the urgent granular raw materia EPT into critical pill device.

Tableting technologies:

If the drug tablets have the following houses:

1, with a particular diploma of mobility

2, has a specified viscosity

3, do not paste the punch and die ring (powder dry)

4, the situation body fluids speedy disintegration, dissolution, absorption and efficacy have generated exceptional tablets can be ready.

Pill push machine basic principle and construction

1 turret structure: the turntable is the primary piece of the device to perform the work. Higher and lower bearing assemblies, spindle, turntable and EPT main elements of composition. Evenly dispersed close to the turntable on the pair dies, between the turntable and the spindle torque transmitted from the flat crucial. Spindle supported on bearings, spline linked by a worm gear generate, rotating spindle, rotating the turntable work.

two, keep track of mechanism: monitor has a concave cylindrical cam and flat wheel and decrease rai EPT consisting of a prime and bottom punch track rod motion. Rushed from the rai EPT on the monitor, on the crimson downward observe, on a parallel track rushed, rushed down on parallel tracks and EPT rail strain block orbitals. They are secured to the upper rail plate. Underneath keep track of rail line by the rushed, rushed down the rail line and filling unstable components. They are mounted on the reduced rail seat.

3, filling adjustment implies: filling adjustment for modifying the excess weight of the tablet. Filling the adjustment mechanism inside of the major human body of the apparatus, a plane on the human body can be observed crescents filling rail, which consists of the action of the helical raised or decreased to manage the filling amount, when the disc is rotated adjustment, lowering the amount of filling clockwise, and vice versa plus Big.

four, sheet thickness (strain) regulator: down beneath the pressure wheel by altering slice thickness adjustment (pressure). Underneath strain wheel mounted on the tank physique, it sets the eccentric shaft is linked to the outer end of the hand wheel, when the external hand wheel adjustment, eccentric shaft driven compression wheel up or down, the flap thickness (strain), thereby management pill thickness and hardness. Force on the wheel up and down adjustment can also be employed as adjusting implies, but in general is not altered.

5, transmission: transmission gearbox is portion of the device is composed of motor, timing belt pulleys and worm gears, whee EPT and EPT elements te EPT driver. Motor mounted on the bottom plate of the motor foundation, soon after the motor starts, by a pair of timing belt to transfer electrical power to the worm equipment reducer web. Motor pace is altered by the variable pace AC frequency. Open up sides or back doorway, can be right observed and speak to with these parts.

| Design | ZP-5B | ZP-7B | ZP-9B |

| module | five | 7 | 9 |

| Max. tablet dia. | 18mm | 18mm | 18mm |

| Max.force | forty | forty | 40 |

| Max. filling depth | fifteen | 15 | 15 |

| Max. tablet thickness | 6 | 6 | six |

| Disc pace(r/min) | thirty | thirty | thirty |

| Capcity (personal computer/hr) | 9000 | 12500 | 16000 |

| Motor energy(KW) | 1.5 | one.five | 1.5 |

| Dimension (mm) | 450*460*950 | 450*460*950 | 450*460*950 |

| Voltage | 220/380 | 220/380 | 220/380 |

| Fat | a hundred and eighty | 180 | a hundred and eighty |

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 diverse branches. For far more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original equipment manufacturer’s (OEM) portion figures or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our organization and the shown substitute elements contained herein are not sponsored, accepted, or made by the OEM.

External best made in China – replacement parts – in Ribeirao Preto Brazil Pulley 240mm Gearless Traction Machine Load Capacity 680kg with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Permanent magnet synchronous Gearless traction machine for elevator:

-Capacity load: 630KG

-Max.Static Load: 3000KG

-Wrap:Single

-Insulation:F

-Protection:IP41

-Traveling Height:≤Rated Speed * 45

-Driving equipment,motor of elevtor.

-Small volume,energy saving, environmental protection, stable operation & Low NVH.

Specification of Gearless traction machine:

| Model | WTD2-P |

| Capacity (kg) | 630 |

| EPT Speed (m/s) | 0.4-0.5 |

| Rated Voltage | AC380V |

| Dia. Of Sheave (mm) | 320 |

| Ropes | 3 x Φ8 |

| Groove Distance (mm) | 12 |

| Brake Power | DC110V |

| Poles | 20 |

| Color | BLACK&RED |

| Brand | XIHU (WE EPT LAKE) DIS. |

| Packing | 1PC/Wooden Case |

| Wooden Case Measurement | 760*485*600=0.22CBM |

| Payment Term | T/T, L/C |

| Delivery Time | 15 days |

| Certificates | CE, ISO9001, ISO14001:2004,IATF16949 |

| Mass Production Time | 30 days |

Similar traction machines photos:

Company Profile:

*Xihu (We EPT Lake) Dis. Power Co., Ltd. was establised in 2571 which owns two manufacturing bases: Xihu (We EPT Lake) Dis. Power(ZheJiang ) Co., Ltd. & Xihu (We EPT Lake) Dis. Power(ZheJiang )Co., Ltd.

*It has more than 1000 workers & covers over a area of 110,000m2. Advanced R&D team which with more than 110 staffs.

*Certificates: IATF16949, UCMP & CE, ISO9001:2015, ISO45001:2018

*The Chinese Academy of Science Co-engineering Unit was established since 2013.

*Awarded the “National EPT Enterprise” & obtained the “National Hi-Tech Innovation Fund Project Reward”.

*With competitive, high quality & good service, we win a good reputation both at home & abroad.

Traction Machine worshop:

EVM (Electric Vehicle Motor) Workshop:

Certificates:

Attend Fairs:

FAQ:

1.What is your delivery time?

15-20days after get the deposit.

2.What is your payment?

T/T & L/C optional

3.How long is your warranty period?

2 years after deliveried

4.Do you have any certificates?

CE,SGS,ISO9001,IATF16949,Etc

5.Do you have the import & export license?

We are official import & export licensed manufacturer.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

Air made in China – replacement parts – in Cherthala India Cooling 3 Axis Wood Cutting Machine 2030 CNC Router for Sale with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 distinct branches. For much more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Air cooling 3 axis wood chopping equipment 2030 cnc router for sale

Principal attributes

one.Strong steel structure, good rigidity, non-forming, sturdy.

two. Large precision tends to make it appropriate for the arts and crafts marketing market.

three.Layout: interface use of global regular G code guidelines, carving compatible at home and overseas, simple to run it.

substantial high quality with realistic price tag , economic.

four.High velocity driver and stepper motor could boost operate efficiency.

Specialized Info:

| Description | Parameter |

| Model | FM2030 |

| X,Y,Z operating spot | 2000* 3000* 200mm |

| Table measurement (mm) | 2000* 000mm |

| Resolution | ±0.03/300mm |

| Repeatability | ±0.03mm |

| Desk Construction | Vacuum desk |

| Lathe Composition | Welding metal structure |

| X,Y structure | Rack pinion, Hiwin linear rails |

| Z framework | TBI Ball screw, Hiwin square rails |

| Rated energy | 3Kw (with out spindle) |

| Max. speedy | 32000mm/min |

| Max. Functioning velocity | 25000mm/min |

| Spindle electricity | 5.5Kw spindle |

| Spindle pace | -24000RPM |

| Functioning manner | Stepper or servo |

| Doing work voltage | AC380V/fifty/60Hz,3Ph(Alternative 220V,3Ph) |

| Command code | G code |

| Working system | Mach3 system (Ncstudio, Syntec,D EPT ) |

| Interface | USB |

| Memory | 128M |

| Device holder | ER25 |

| X,Y doing work accuracy | <0.03mm |

| Computer software | Artcam, Type3 UcancameV9 |

| Operating temperature | Temperature: degree-forty five diploma Humidity:thirty%-75% (No Condensation) |

| Optional Spare Components | Air-cooling spindle |

| Double bag du EPT collection,vacuum pump | |

| rotary |

Primary configuration

Software industry and materials

Household furniture industry: wood doors, home windows, folding screens, tables, chairs, and many EPT materia EPT this sort of as plastic board, PVC sheet, dual coloration board, aluminum, and so on.

Primarily for the manufacturing of cabinet door, real wooed, the home furniture and so on, also can be used in the generation of MDF cutting.

Samples

Our Providers

one.One yr warranty,main components are free of charge of demand when difficulties transpired throughout the assure interval.

2.Existence time free of charge servicing provider.

three.Free training system at our factory with skilled engineers.

four.We offer the consumable elements at agent price when you need to have substitution

five.24 several hours on the web support every day,free technological assist with distinct languages.

Packiing and shiping

1. Outdoors bundle: Normal maritime export plywood situation.

2. Inner package deal: A few layers in whole EPE pearl cotton film+PE stretchy movie.

three.Improved bundle, significantly more strong and environmental security.

four.We can also make package deal according to your requests.

Shipping Detail: Delivered in twenty five-30 working times after payment.

EPT various kinds of cnc router devices

# Linear or Circular kind ATC wooden cnc router

# Pneumatic 4 head ATC cnc router

# Wood cnc router with air cooling spindle

# Wood cnc router with water cooling spindle

# Mini cnc router for wooden advertising and marketing

# Double heads wooden cnc router

Company Information

HangZhou Firm CNC Gear Co., Ltd is located in HangZhou town, ZheJiang province. We are a professional and great status company of CNC router,laser engraving machine, CNC plasma cutter, laser chopping machine, laser marking equipment in China to the new and current customers that are spread all through the South The united states, Middle East, Southea EPT Asia, Africa, Europe and EPT counties of the globe and the machines has passed the EU CE SGS certificate.The intention of HangZhou Company CNC Router is to continuously update the approach, to support our clients create the be EPT high quality and high precision items.

Consumer pay a visit to manufacturing unit

FAQ

Query 1:How lengthy about the machine’s ensure ?

Answer :2 several years

Concern 2:How about your after service ?

Solution :Technological assist by mobile phone, e-mail or MSN all around the clock.

Concern 3: How can we put in the equipment?

Solution :Pleasant English variation guide and procedure movie CD disk.

Concern 4: How about the payment conditions?

Solution:30% T/T for deposit, 70%T/T compensated before shipping and delivery.

T/T, We EPT Union, Paypal

Query 5: Do You Set up Shipment For The Devices?

Reply: Of course, dear esteemed consumers, for FOB or CIF cost, we will set up cargo for you.

For EXW price tag, customers need to arrange shipment by on their own or their agents.

The use of original gear manufacturer’s (OEM) portion numbers or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our firm and the detailed alternative elements contained herein are not sponsored, authorized, or created by the OEM.

Best China manufacturer & factory China in Managua Nicaragua manufacturer for OEM Manufacturing Precision cnc machined central machinery milling machine parts With high quality best price

If you need any data or samples, remember to speak to us and you will have our quickly reply.

Overview

Fast Information

- Relevant Industries:

-

Manufacturing Plant

- Model Title:

-

OEM

- OEM Provider:

-

Support

- Tolerance:

-

.01-.05mm or Personalized

- Certification:

-

ISO9001, SGS

- Surface area Treatment method:

-

Sandblasting,Sharpening,Anodize, Zinc,Nickel,Chrome,Plating, and so forth.

- Software:

-

Auto,Health-related Equipments,Electric powered Appliance,Components,and so forth.

- Dimension:

-

As Customers’ Request

- Gear:

-

Milling/Lathe/Drilling/4/3 Axis CNC Machining Centre

- Drawing Format:

-

Pro/E, Automobile CAD, Solid Performs,IGS,UG, CAD/CAM/CAE

Supply Potential

- Offer Capability:

- 10000 Piece/Parts for every Thirty day period

Packaging & Supply

- Port

- Ningbo, Shanghai

-

Lead Time

: -

Quantity(Bags) one – five hundred >500 The EP Line PTO push shafts are recognizable due to the fact of the EP Line patented coupling system and the flexible cone. The PTO travel shafts are distinguished by way of person-friendliness, compactness and interesting design.

Est. Time(times) 30 To be negotiated

On-line Customization

OEM Manufacturing Precision cnc machined central equipment milling equipment areas

Item Description

| Product Variety | CNC turning, milling, drilling, grinding, wire EDM slicing etc. |

| Our Providers | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Generating,and many others |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wooden,Silicone,Rubber,Or as for each the customers’ specifications |

| Surface Treatment method |

Anodizing,Sandblasting,Portray,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ ask for |

| Service Venture | To provide production layout, manufacturing and complex support, mould development and processing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Device | Digital Peak Gauge, caliper, Coordinate measuring equipment, projection equipment, roughness tester, hardness tester and so on |

| Industry used | Machinery heavy responsibility tools digital system Automobile spare areas optical telecommunication |

| Packing | Eco-welcoming pp bag / EPE Foam /Carton bins or picket boxes As customer’s certain demands |

| Trial sample time | 7-ten days after affirmation |

| Delivery time | 7-thirty times after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Provider

OEM Components

Surface area Treatment

Creation Procedure

Why Us

Packing made in China – replacement parts – in Esfahan Iran Machine Separation Modular Chain Belt with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Name&Describtion

Packing Device separation modular chain&lparB&rpar belt

&lparHairise900&rpar

| 1 | Packing Device separation modular chain&lparB&rpar belt &lparHairise900&rpar | ||

| two | Material&colon POM&solPP | ||

| three | Pitch&colon27&period2mm | ||

| four | Thicknes&colon14mm | ||

| five | Open spot&colon17&percnt | ||

| six | Processing&colon injection molding and acknowledge custom-made | ||

| seven | Hign good quality Content &colonDupont Delrin&lparproviding certification&rpar | ||

| eight | Temperature&colon -40~90ºC | ||

| 9 | Application&colon Foodstuff & Beverage &Packing induatry conveying | ||

| ten | Mass production in a short time&ensure higher performance | ||

EPT plastic modular conveyor belt

EPT belts and chains are created of plastic modules&period of time Belts are assembled in

an interlocked&commabricklayed sample with total-size hinge rods – an inherently

robust design&periodOf system &commawe can also supply snap link style&period of time

EPT invented this technological innovation from2004 and has considerably experience in the

design and application of modular plastic conveyor belts

1&periodPitch&period EPT belts are available in &period39”&lpar10mm&rpar&comma0&period5″ &lpar12&period7 mm&rpar&comma

&period6″ &lpar15&period2 mm&rpar&comma &period74”&lpar18&period9mm&rpar&comma0&period75”&lpar19&period05&rpar&comma1″ nominal &lpar25&period4 mm and

27&period2 mm&rpar&comma1&period1”&lpar27&period9mm&rpar&comma1&period25″ &lpar31&period8 mm&rpar&comma 1&period47”&lpar37&period5mm&rpar1&period5″ &lpar38&period1mm&rpar&comma

one&period73”&lpar44mm&rpar&comma1&period97”&lpar50mm&rpar&comma2″ &lpar50&period8mm&rpar and 2&period15″&lpar54&period5mm&rpar &comma

2&period25”&lpar57&period15mm&rparpitches&period

Scaled-down pitch belts&comma when employed in excess of similar dimensions sprockets&comma reduce the quantity

of space required for product transfer&period

2&period Toughness&time period 1 of Hairise’s associates can aid make sure that the belt

you pick will provide sufficient toughness for your software by utilizing the Intralox

or Habasit or Rexnord and so on EPT Plan&comma which evaluates the

suitability of a belt in mild of several variables&comma like size&commaload&comma velocity&comma and so on&time period

three&periodSprockets&interval For each certain belt collection&comma various sprockets with various

combinations of pitch diameter&commanumber of tooth&comma resources&comma and&solor layout could be obtainable&interval

EPT supplies equipment and injection sprocket for consumer to satisfy any

demands&time period

four&periodAccessories&period of time A variety of equipment are available for diverse belt sequence to satisfy the wants of your purposes&interval Various of flights&comma sideguards&comma wearstrips&comma and finger transfer plates&period

five&periodHairise’s products have been extensively utilized in food processing of meat&comma frozen meals&comma sea meals&comma bakery&comma and dairy goods&time period The plastic conveyor belt and chain also engage in an crucial role in pharmacy&comma chemical&comma packaging&comma electonics and EPT industries&period of time

Mujia organization is a manufacturer not a trade firm&period

Mujia organization offers substantial top quality solutions with historical track record

EPT belt ptovides a whole servise from design to generation&commaWe strictly be aware the top quality&period

Settle for custom-made modular belt and top conveyor chains&interval

EPT belts supplies Reduced price tag with exceptional top quality and substantial overall performance&interval

EPT belts supplies Very good bundle&commasafe and swift delivery

RFQ&colon

1&periodI do not know what belt I currently have&periodCan you help me discover my belt&quest

Our on-line belt identifier can aid you slender down the collection and style of your recent belt&periodIf you need far more certain info on your belt&commacontact me freely&period

two&periodDoes EPT offer PDF documents or samples&period of time

Yes&commayou can get PDF documents from me for a large number of our items&time period

If you can’t discover what you are searching for&commasend me your reque EPT by email&period of time

If you still not affirm the belt type&commafree sample is offered&time period

three&periodWhat can you do If the products had been damaged&quest

&lpar1&period&rparIf merchandise were broken once you acquired from me&commaI would change them freely

&lpar2&interval&rparIf the goods have been broken when you utilized&commaWe could offer 1 year good quality ensure under frequent doing work surroundings&period of time

Buyer Service – Available 24 several hours a day&comma 365 days a year &time period

Mujia EPT Engineering &lparZheJiang &rparcompany minimal

Gerall Hang

Whatspp&colon&plus86~13083988828 13858117778695253717

The use of unique products manufacturer’s (OEM) portion figures or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating solution use and compatibility. Our organization and the listed replacement elements contained herein are not sponsored, accredited, or produced by the OEM.