Product Description

Product Description

| model | XLJ-G-75D |

| voltage | DV18V |

| Cut Material | Copper aluminum wire |

| Charging time | About 2 hours |

| Number of uses | About 100 times |

| weight | 3.6kg |

| Cutting range | Suitable for copper aluminum wires with an outer diameter of less than 70mm |

1.Before use, it is necessary to check for any damage or aging, and replace the shear in a timely manner.

2. Do not place your fingers at the edge of the knife to avoid accidents.

3. Do not use excessive force during cutting to avoid damaging the shear or material.

4. During operation, it is important to remain alert, pay attention to safety, and avoid accidents.

5. After use, timely cleaning and maintenance should be carried out to ensure the lifespan and effectiveness of the shear.

In short, the correct use of ratchet cable cutters can not only improve work efficiency, but also ensure operational safety and material quality.

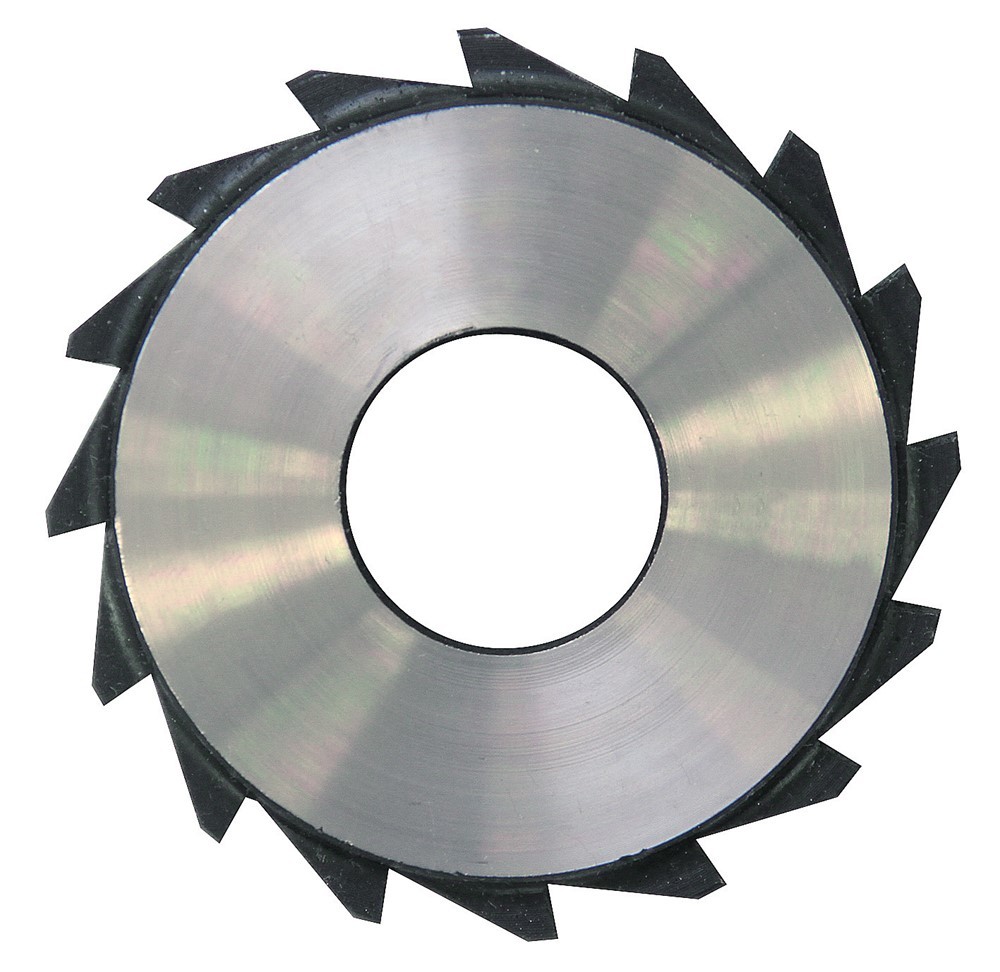

6.Cast blade with long service life

7.The new electric ratchet cutter for stable cutting adopts a composite integrated hard blade design, which is lightweight and strong, ensuring cutting quality; The product is equipped with high-performance motors, which provide CHINAMFG power support during use, ensuring smooth cutting.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, ISO |

|---|---|

| Condition: | New |

| Automatic Grade: | Automatic |

| Brand: | Yikai |

| Blade Material: | Copper Stranded Wire |

| Charging Time: | About Two Hours |

| Customization: |

Available

|

|

|---|

How does the choice of materials impact the durability and performance of ratchet wheels?

The choice of materials significantly impacts the durability and performance of ratchet wheels in mechanical systems. Different materials offer varying levels of strength, wear resistance, and corrosion resistance, influencing how well the ratchet wheel performs over time. Here’s how material selection affects ratchet wheel characteristics:

- 1. Strength and Load Capacity: The material of a ratchet wheel determines its strength and load-bearing capacity. High-strength materials like hardened steel or alloy steel are often chosen for heavy-duty applications, as they can withstand substantial loads without deformation or failure.

- 2. Wear Resistance: Ratchet wheels are subject to wear and friction as they engage with pawls or catches. Materials with excellent wear resistance, such as hardened steel or materials with special coatings, can prolong the lifespan of the ratchet wheel by reducing wear and preventing premature tooth damage.

- 3. Corrosion Resistance: In environments where exposure to moisture, chemicals, or corrosive substances is a concern, selecting corrosion-resistant materials is crucial. Stainless steel and certain alloys are known for their resistance to rust and corrosion, making them suitable for such conditions.

- 4. Weight Considerations: The material’s density impacts the weight of the ratchet wheel. Lighter materials, such as aluminum or certain plastics, can be chosen when weight reduction is a priority, especially in applications where portability or reduced inertia is essential.

- 5. Friction and Efficiency: The material’s surface properties can affect friction and overall efficiency. Some materials may require lubrication to reduce friction, while others have inherent properties that promote smooth engagement and reduce energy losses.

- 6. Cost and Availability: Material choice also affects the cost and availability of ratchet wheels. Common materials like steel are readily available and cost-effective, while specialized materials may be more expensive and less accessible.

- 7. Temperature Resistance: For applications in extreme temperature environments, materials must be chosen that can withstand temperature variations without deformation or loss of mechanical properties.

- 8. Compatibility with Pawls: The material of the ratchet wheel should be compatible with the material of the pawl or catch mechanism to ensure proper engagement and prevent premature wear of either component.

Ultimately, the choice of material should align with the specific requirements of the application. Engineers and designers carefully consider factors such as load capacity, wear resistance, environmental conditions, and cost to select the most suitable material for ratchet wheels, ensuring optimal durability and performance in the intended use.

Are there innovations or advancements in ratchet wheel technology that have emerged recently?

Yes, there have been notable innovations and advancements in ratchet wheel technology in recent years. These developments aim to enhance the performance, efficiency, and versatility of ratchet wheels in various applications. Some of the key advancements include:

- 1. Materials and Coatings: Advances in materials science have led to the development of ratchet wheels made from high-strength and lightweight materials. These materials offer improved durability and reduced wear, extending the service life of ratchet wheels. Additionally, specialized coatings are applied to enhance corrosion resistance and reduce friction.

- 2. Precision Manufacturing: Modern manufacturing techniques, including CNC machining and 3D printing, allow for the production of highly precise ratchet wheel components. This precision ensures smoother engagement and more accurate positioning, making ratchet wheels suitable for applications requiring tight tolerances.

- 3. Miniaturization: In industries like electronics and medical devices, there is a demand for smaller and more compact ratchet mechanisms. Recent advancements have led to miniaturized ratchet wheels that can operate in confined spaces while maintaining their precision and reliability.

- 4. Smart Ratchet Systems: Some innovative ratchet systems incorporate smart technology, such as sensors and feedback mechanisms. These systems can monitor the position and condition of the ratchet wheel in real-time, providing valuable data for diagnostics and maintenance.

- 5. Enhanced Safety Features: Advancements in safety-critical applications have resulted in ratchet wheels with enhanced safety features. These may include fail-safe designs, improved locking mechanisms, and more robust materials to withstand extreme conditions.

- 6. Integration with Automation: Ratchet wheels are increasingly being integrated into automated systems, where they play a crucial role in controlled motion and positioning. These integrated solutions improve efficiency and reduce the need for manual adjustments.

- 7. Customization: Manufacturers now offer greater customization options for ratchet wheels to meet specific application requirements. This includes variations in tooth profiles, sizes, and configurations to accommodate diverse needs.

- 8. Sustainable Materials: As sustainability becomes a more significant concern, there is a growing trend toward using eco-friendly materials in ratchet wheel production. This includes the use of recycled and recyclable materials in their construction.

These innovations in ratchet wheel technology contribute to their adaptability in various industries and applications. Whether it’s improving precision, enhancing safety, or reducing environmental impact, recent advancements have expanded the capabilities of ratchet wheels in mechanical systems.

What are the different types and sizes of ratchet wheels available in the market?

Ratchet wheels come in various types and sizes to accommodate a wide range of applications. The choice of ratchet wheel type and size depends on factors such as load capacity, space constraints, and the specific requirements of the mechanical system. Here are some common types and sizes of ratchet wheels available in the market:

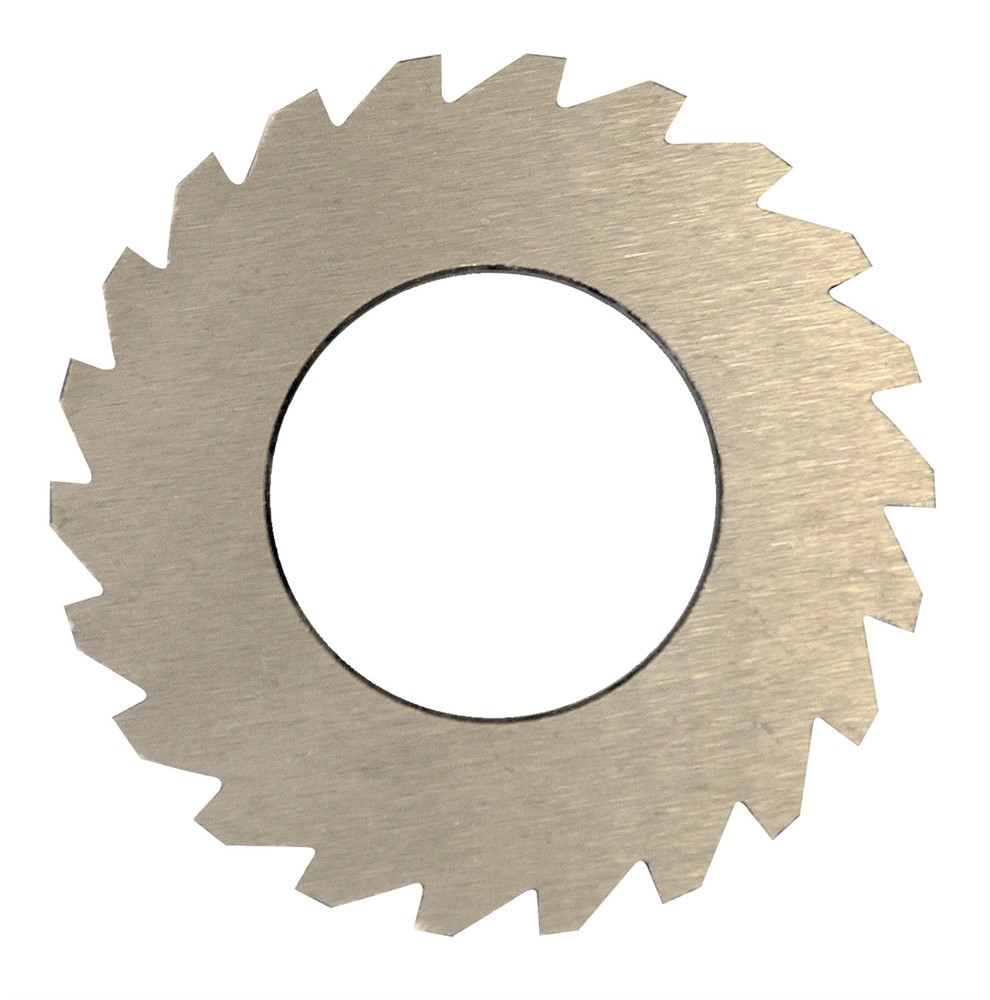

- 1. Standard Ratchet Wheels: These are the most common type of ratchet wheels, featuring a set of angled teeth that engage with a pawl or catch mechanism. Standard ratchet wheels are available in a variety of sizes, typically ranging from small diameters (e.g., a few inches) to larger ones (e.g., a foot or more) to accommodate different applications.

- 2. Fine-Tooth Ratchet Wheels: Fine-tooth ratchet wheels have smaller and more closely spaced teeth compared to standard ratchet wheels. This design allows for finer control and incremental movement in applications where precision is critical. Fine-tooth ratchet wheels are often used in instruments, delicate machinery, and applications requiring precise adjustments.

- 3. Large Diameter Ratchet Wheels: In heavy-duty applications such as industrial machinery and material handling equipment, large diameter ratchet wheels are employed to handle substantial loads. These ratchet wheels can have diameters exceeding a foot or more, providing the necessary strength and engagement surface for robust performance.

- 4. Miniature Ratchet Wheels: Miniature ratchet wheels are designed for compact and space-restricted applications. They are smaller in size, typically measuring fractions of an inch in diameter. These miniature ratchet wheels are commonly used in electronics, medical devices, and precision equipment.

- 5. Custom Ratchet Wheels: For specialized applications or when off-the-shelf ratchet wheels do not meet specific requirements, custom ratchet wheels can be manufactured. Customization allows for tailoring the size, tooth profile, and material to suit unique applications and load capacities.

- 6. Corrosion-Resistant Ratchet Wheels: In environments where corrosion is a concern, ratchet wheels may be available with special coatings or materials that enhance their resistance to rust and corrosion. These ratchet wheels are suitable for marine, outdoor, or humid conditions.

The availability of ratchet wheel types and sizes in the market ensures that industries and applications of all scales can find the appropriate ratchet wheel to meet their specific needs. Whether it’s for heavy-duty machinery or precision instruments, ratchet wheels come in various configurations to support a wide range of mechanical systems.

editor by CX 2024-02-25

China factory Ratchet Cable Scissors Gear Copper Aluminum Pliers Steel Strand Scissors Professional Hydraulic Cable Cutter Steel Rebar

Product Description

Product Description

| model | XLJ-G-75D |

| voltage | DV18V |

| Cut Material | Copper aluminum wire |

| Charging time | About 2 hours |

| Number of uses | About 100 times |

| weight | 3.6kg |

| Cutting range | Suitable for copper aluminum wires with an outer diameter of less than 70mm |

1.Before use, it is necessary to check for any damage or aging, and replace the shear in a timely manner.

2. Do not place your fingers at the edge of the knife to avoid accidents.

3. Do not use excessive force during cutting to avoid damaging the shear or material.

4. During operation, it is important to remain alert, pay attention to safety, and avoid accidents.

5. After use, timely cleaning and maintenance should be carried out to ensure the lifespan and effectiveness of the shear.

In short, the correct use of ratchet cable cutters can not only improve work efficiency, but also ensure operational safety and material quality.

6.Cast blade with long service life

7.The new electric ratchet cutter for stable cutting adopts a composite integrated hard blade design, which is lightweight and strong, ensuring cutting quality; The product is equipped with high-performance motors, which provide CHINAMFG power support during use, ensuring smooth cutting.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, ISO |

|---|---|

| Condition: | New |

| Automatic Grade: | Automatic |

| Brand: | Yikai |

| Blade Material: | Copper Stranded Wire |

| Charging Time: | About Two Hours |

| Customization: |

Available

|

|

|---|

Can you provide examples of machinery or equipment that commonly use ratchet wheels?

Ratchet wheels are commonly used in various machinery and equipment across different industries due to their ability to provide controlled motion and security. Here are examples of machinery and equipment that commonly incorporate ratchet wheels:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, utilize ratchet wheels to enable continuous tightening or loosening of nuts and bolts without the need to remove and reposition the wrench. The unidirectional motion of the ratchet wheel allows for efficient and convenient use.

- 2. Winches and Hoists: Winches and hoists, whether manual or powered, frequently employ ratchet wheels in their mechanisms. Ratchet wheels ensure controlled lifting, lowering, or pulling of loads while preventing unintended backdriving.

- 3. Handbrakes in Vehicles: Many vehicles, especially older models, feature handbrake systems that rely on ratchet wheels. These ratchet mechanisms secure the vehicle’s position when the handbrake lever is engaged, preventing the vehicle from rolling.

- 4. Tie-Down Straps: Ratchet mechanisms are integral components of tie-down straps used for securing cargo during transportation. They maintain tension in the strap and prevent slack, ensuring that the load remains securely fastened.

- 5. Conveyor Systems: Conveyor systems in manufacturing and logistics often incorporate ratchet wheels to control the movement of items along the conveyor belts. Ratchet wheels enable precise indexing and positioning of products.

- 6. Scaffold Systems: Scaffold systems used in construction frequently feature ratchet wheels in their height adjustment mechanisms. Workers can raise or lower scaffolding platforms incrementally, ensuring safety and stability.

- 7. Fishing Reels: Fishing reels, such as baitcasting and trolling reels, use ratchet wheels in their drag systems. This allows anglers to smoothly reel in fish while preventing the fish from pulling out line unintentionally.

- 8. Safety Mechanisms: Various safety mechanisms and emergency stop systems employ ratchet wheels to ensure that once activated, the system remains in a safe state until intentionally reset. This is crucial in industrial and machinery safety applications.

These examples demonstrate the versatility of ratchet wheels in different industries and applications where controlled motion, security, and prevention of reverse movement are essential requirements.

How does the choice of ratchet wheels affect the overall performance and reliability of mechanical systems?

The choice of ratchet wheels plays a significant role in determining the overall performance and reliability of mechanical systems. Here’s how different factors related to ratchet wheel selection impact these aspects:

- 1. Load Capacity: The load capacity of the chosen ratchet wheel must match the intended application. Using a ratchet wheel with insufficient load capacity can lead to premature wear, slippage, and safety risks.

- 2. Material Selection: Ratchet wheels are available in various materials, such as steel, stainless steel, and plastic. The choice of material affects factors like durability, corrosion resistance, and weight. Selecting the appropriate material for the environment and application is critical.

- 3. Tooth Profile and Design: The tooth profile and design of the ratchet wheel impact how well it engages with the pawl or catch. Proper tooth design ensures reliable engagement, reducing the risk of slippage or unintended movement.

- 4. Precision and Tolerance: High-precision ratchet wheels with tight tolerances provide smoother and more consistent operation. Precision is essential in applications where accuracy and repeatability are critical.

- 5. Pawl Compatibility: Ensure that the selected ratchet wheel is compatible with the accompanying pawl or catch mechanism. Incompatibility can lead to issues with engagement and reliability.

- 6. Surface Finish: The surface finish of the ratchet wheel affects friction and wear. A polished or treated surface can reduce friction, extend the service life, and enhance performance.

- 7. Environmental Considerations: Consider the environmental conditions in which the ratchet wheel will operate. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized materials or coatings to maintain reliability.

- 8. Maintenance Requirements: Some ratchet wheels may require more frequent maintenance than others. Understanding the maintenance needs of the chosen ratchet wheel is crucial for long-term reliability.

- 9. Compliance with Standards: Ensure that the selected ratchet wheel complies with industry standards and regulations. Compliance is essential for safety and reliability in specific applications.

- 10. Cost-Benefit Analysis: Consider the cost-effectiveness of the chosen ratchet wheel. While high-quality options may come at a higher price, they often offer better long-term reliability and reduced maintenance costs.

- 11. Application-Specific Features: Some ratchet wheels may offer features tailored to specific applications, such as noise reduction or enhanced security. Choosing a wheel with the right features can improve overall system performance.

- 12. Supplier Reputation: The reputation and reliability of the supplier or manufacturer also play a role. Established suppliers with a track record of quality can offer assurance in the performance of their products.

In summary, the choice of ratchet wheels affects the overall performance and reliability of mechanical systems by influencing load capacity, material selection, tooth design, precision, and many other factors. Selecting the right ratchet wheel for a given application is crucial for achieving optimal system performance and longevity.

In what mechanical devices or tools are ratchet wheels commonly used, and how do they operate?

Ratchet wheels are commonly used in various mechanical devices and tools, where they play a crucial role in enabling unidirectional motion and preventing backward movement. Here are some examples of mechanical devices and tools that incorporate ratchet wheels and an explanation of how they operate:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, are widely used in automotive repair and mechanical work. They feature a ratchet wheel mechanism in the wrench head. When the user turns the handle in one direction, the ratchet wheel engages with the socket, allowing continuous rotation for fastening or loosening bolts or nuts. When the direction is reversed, the ratchet wheel disengages, preventing backward motion and allowing the user to reposition the wrench without removing it from the fastener.

- 2. Ratchet Straps and Tie-Downs: Ratchet straps and tie-downs are used for securing cargo on trucks, trailers, and in various transportation applications. They consist of a ratchet mechanism and a strap with hooks. By cranking the ratchet handle, the ratchet wheel tightens the strap, providing secure tension. The ratchet prevents the strap from unwinding or loosening during transit, ensuring that the load remains securely fastened.

- 3. Handbrakes in Vehicles: In automobiles, ratchet wheels are a fundamental component of handbrakes (parking brakes). When the handbrake lever is pulled, it engages a ratchet mechanism that locks the rear wheels in place, preventing the vehicle from rolling when parked on an incline. Releasing the handbrake disengages the ratchet, allowing normal wheel rotation.

- 4. Winches and Hoists: Winches and hoists used in industries such as construction, manufacturing, and material handling rely on ratchet wheel mechanisms. The ratchet wheel controls the winding and unwinding of cables or ropes. When the user operates the winch or hoist in one direction, the ratchet allows the cable to be pulled in and wound onto a drum. In the opposite direction, the ratchet prevents the cable from unwinding, ensuring controlled load handling.

- 5. Bike Gears: Bicycle gears often use ratchet mechanisms to control gear shifting. When a cyclist pedals forward, the ratchet wheel engages with the gear sprocket, allowing the chain to move smoothly and propel the bike. If the cyclist pedals backward or stops pedaling, the ratchet prevents the chain from moving in reverse, ensuring efficient pedaling and preventing the bike from rolling backward.

- 6. Fishing Reels: Many fishing reels, including spinning reels and baitcasting reels, incorporate ratchet mechanisms. The ratchet wheel in the reel allows the fishing line to be pulled in when the angler reels in a fish. The ratchet prevents the line from spooling out when there is no tension on it, ensuring that the line remains taut during fishing.

In each of these applications, the ratchet wheel functions by engaging with a pawl or catch mechanism. When force is applied in the desired direction, the pawl allows the ratchet wheel to rotate freely, enabling the intended motion. When force is applied in the opposite direction, the pawl engages with the teeth on the ratchet wheel, locking it in place and preventing backward movement. This simple yet effective mechanism provides controlled and safe operation in various mechanical devices and tools.

editor by CX 2024-02-23

China factory Electric Ratchet Shears Cable Shears Professional Hydraulic Cable Cutter Steel Rebar

Product Description

Product Description

| model | XLJ-G-75D |

| voltage | DV18V |

| Cut Material | Copper aluminum wire |

| Charging time | About 2 hours |

| Number of uses | About 100 times |

| weight | 3.6kg |

| Cutting range | Suitable for copper aluminum wires with an outer diameter of less than 70mm |

1.Before use, it is necessary to check for any damage or aging, and replace the shear in a timely manner.

2. Do not place your fingers at the edge of the knife to avoid accidents.

3. Do not use excessive force during cutting to avoid damaging the shear or material.

4. During operation, it is important to remain alert, pay attention to safety, and avoid accidents.

5. After use, timely cleaning and maintenance should be carried out to ensure the lifespan and effectiveness of the shear.

In short, the correct use of ratchet cable cutters can not only improve work efficiency, but also ensure operational safety and material quality.

6.Cast blade with long service life

7.The new electric ratchet cutter for stable cutting adopts a composite integrated hard blade design, which is lightweight and strong, ensuring cutting quality; The product is equipped with high-performance motors, which provide CHINAMFG power support during use, ensuring smooth cutting.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, ISO |

|---|---|

| Condition: | New |

| Automatic Grade: | Automatic |

| Brand: | Yikai |

| Blade Material: | Copper Stranded Wire |

| Charging Time: | About Two Hours |

| Customization: |

Available

|

|

|---|

How do ratchet wheels differ from other types of gears in terms of functionality?

Ratchet wheels differ from other types of gears in terms of functionality primarily due to their unidirectional motion and ability to prevent backward movement. Here are key distinctions between ratchet wheels and other gears:

- 1. Unidirectional Motion: Ratchet wheels are designed to allow motion in only one direction. When force is applied in the desired direction, the ratchet wheel rotates freely, enabling movement. In contrast, traditional gears, such as spur gears or helical gears, transmit motion bidirectionally—both clockwise and counterclockwise.

- 2. Prevention of Backward Movement: The defining feature of ratchet wheels is their ability to prevent backward movement. This is achieved through the engagement of a pawl or catch mechanism with the teeth of the ratchet wheel. The pawl locks the ratchet wheel in place when force is applied in the opposite direction, effectively preventing any reverse motion. Traditional gears do not have this locking capability and allow bidirectional movement without restriction.

- 3. Incremental Motion Control: Ratchet wheels are often used in applications where precise incremental motion control is required. The teeth on a ratchet wheel are typically spaced in a way that allows for controlled, step-by-step movement. This is advantageous in scenarios where precise positioning or adjustments are necessary, such as in ratchet wrenches or fine-tooth ratchet wheels.

- 4. Limited Gear Ratio: Unlike traditional gears that can provide variable gear ratios to change speed and torque, ratchet wheels offer a fixed gear ratio. They are not used for speed reduction or torque amplification but rather for controlled and secure movement in one direction.

- 5. Specialized Applications: Ratchet wheels are commonly found in specific applications where their unidirectional and locking capabilities are crucial. These include hand tools like ratchet wrenches, winches, tie-down straps, handbrakes in vehicles, and more. Traditional gears are used in a broader range of applications where bidirectional motion is needed, such as in machinery, vehicles, and industrial equipment.

In summary, ratchet wheels excel at providing controlled, unidirectional motion and preventing backward movement. They are specialized components used in applications where these characteristics are essential. Traditional gears, on the other hand, are versatile components that transmit motion bidirectionally and are employed in a wide array of mechanical systems for various purposes.

Can you share tips for selecting the right ratchet wheel based on specific industry requirements and load capacities?

Selecting the right ratchet wheel for your application involves considering industry-specific requirements and load capacities. Here are some tips to help you make an informed choice:

- 1. Determine Load Capacity: Identify the maximum load or torque that your ratchet wheel needs to handle. Choose a ratchet wheel with a load capacity that comfortably exceeds your application’s requirements to ensure safety and reliability.

- 2. Material Selection: Consider the environment in which the ratchet wheel will operate. Stainless steel or corrosion-resistant materials are ideal for outdoor or harsh conditions, while plastic ratchet wheels may be suitable for lighter-duty applications.

- 3. Tooth Profile and Design: The tooth profile and design of the ratchet wheel should match your specific application. For precise control, choose a ratchet wheel with well-designed teeth that engage smoothly with the pawl or catch.

- 4. Precision and Tolerance: In applications where precision matters, opt for ratchet wheels with tight tolerances. High-precision ratchet wheels provide consistent and reliable performance.

- 5. Pawl Compatibility: Ensure that the chosen ratchet wheel is compatible with the pawl or catch mechanism in your system. Proper engagement is essential for reliable operation.

- 6. Surface Finish: A polished or treated surface can reduce friction, extending the ratchet wheel’s service life. Consider surface finish options to enhance performance.

- 7. Environmental Factors: Evaluate the environmental conditions, including temperature, moisture, and exposure to chemicals. Choose a ratchet wheel that can withstand these conditions without compromising performance.

- 8. Maintenance Requirements: Understand the maintenance needs of the ratchet wheel. Some may require periodic lubrication or inspection, while others are maintenance-free. Choose one that aligns with your maintenance capabilities and schedule.

- 9. Compliance with Standards: Ensure that the ratchet wheel complies with industry standards and regulations relevant to your application. Compliance is critical for safety and reliability.

- 10. Cost-Benefit Analysis: Consider the long-term cost-effectiveness of your choice. While high-quality ratchet wheels may have a higher initial cost, they often offer better reliability and reduced maintenance expenses over time.

- 11. Application-Specific Features: Some ratchet wheels come with features tailored to specific applications, such as noise reduction or enhanced security. Explore these options if they align with your needs.

- 12. Seek Expert Advice: If you’re unsure about the best ratchet wheel for your application, consult with industry experts or suppliers. They can provide valuable insights and recommendations based on their experience.

By considering these tips and tailoring your ratchet wheel selection to your industry requirements and load capacities, you can ensure that your mechanical system operates reliably and efficiently.

How does the design of a ratchet wheel contribute to its efficiency and reliability?

The design of a ratchet wheel is critical to its efficiency and reliability in various applications. The following design elements contribute to the effectiveness of ratchet wheels:

- 1. Tooth Profile: The shape and profile of the teeth on a ratchet wheel are crucial. Teeth are typically angled to allow easy engagement with the pawl or catch mechanism when force is applied in the desired direction. The angle of the teeth ensures efficient and secure movement in one direction while preventing backward motion.

- 2. Material Selection: The choice of materials for the ratchet wheel affects its durability and reliability. Ratchet wheels are commonly made of strong and wear-resistant materials such as hardened steel or alloy metals. High-quality materials ensure the wheel can withstand the forces and wear associated with its intended application.

- 3. Tooth Size and Spacing: The size and spacing of the teeth on a ratchet wheel are designed to optimize performance. Smaller teeth allow for finer control and incremental movement, while larger teeth provide stronger engagement for heavier loads. Proper tooth spacing ensures smooth and reliable operation.

- 4. Pawl Design: The design of the pawl or catch mechanism that engages with the ratchet wheel is equally important. The pawl should have a pointed end that effectively grips the teeth when engaged. It should also release easily when force is applied in the opposite direction to allow smooth and reliable operation.

- 5. Lubrication and Maintenance: Adequate lubrication of the ratchet wheel and pawl is essential for reducing friction and wear. Regular maintenance, including cleaning and re-lubrication, ensures the efficient functioning of the ratchet mechanism over time.

- 6. Load Capacity: The design of the ratchet wheel must align with the intended load capacity of the application. Heavier loads may require larger and more robust ratchet wheel designs with deeper teeth to withstand greater forces without slipping.

- 7. Durability and Corrosion Resistance: In applications where exposure to harsh environments or moisture is a concern, ratchet wheels may incorporate coatings or materials that enhance corrosion resistance. This contributes to their long-term reliability.

The combination of these design considerations ensures that a ratchet wheel can efficiently transmit motion in one direction while effectively locking to prevent reverse movement. Proper design contributes to the overall efficiency, reliability, and safety of mechanical systems and tools that rely on ratchet mechanisms.

editor by CX 2024-02-21

in Kozhikode India sales price shop near me near me shop factory supplier Hot Sale Workshop Used 4ton Hydraulic 2 Post Car Lift with Ce manufacturer best Cost Custom Cheap wholesaler

It has recognized steady cooperation with numerous properly identified universities and institutes in china such as, Zhejiang College, Jilin College, Specialized committee of national chain travel standard, Institute of national chain drive, Zhejiang application engineering content institute, Huhan materials protection institute and it cooperated to found China 1st Auto chain institute with National chain generate institute. We are searching ahead to building effective organization relationships with new customers around the planet in the long term. Our company pays particular interest to customers’ needs, listening to the specific demands of every buyer and guaranteeing total gratification.

Hot sale Workshop utilized 4ton EPT two submit vehicle carry with CE

Solution Description

#8226Oli cylinEPTTparts manufactured by automatic large rotation velocity CNC lathe ensure the outstanding finish and EPTity.

#8226Janpanese oil sealing factors, overload safety, international brand oil pipe. #8226Direct EPT twin cylinders, with security steel wire as synchronization. #8226EPTmer dress in-resistance slider. #8226Single aspect safety gadget, a lot more dependable. #8226Gate variety, for operation much more straightforward, no obstruction onto the ground. #8226Roof defense security device, automatic arm lock by developed in ratchet tooth. #8226Shot blasting and substantial temperature baking powEPTTcoated surface end.

EPTT Info

EPT BUCK

EstabEPTTd in 2012, HangEPT Road Buck is a joint knowledge of EPTT company HangEPT conEPTTand Italian Cormach srl which is a well acknowledged foremost XiHu (West EPT) Dis.Hu (West EPT) Dis.age equipment gaint. Devoted in the investigation, deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment, generation, sale and provider of automative maintenance tools, our quality products are nicely approved by customers close to the planet. In 2013, Road Buck has rapidly grow to be the most beneficial automobile detecting products model EPTTly.

Street Buck efficiently introduced an age influencing Street Buck Mini wheel aligner in 2013, which delivers far more EPTT experiences to consumers. quotWhen there is a require, there is Street Buck quot’, this business mission encompasses a team spirit with EPTTrprise, self-assurance and optimism, and also a indicating of uncreasingly self-transcending and relentless pursuit of excellence, which completely signifies the professionlism of the aspiring Street Buck things.

Service

Warranty period:

The warranty period of time:one several years

Service:

one. Adjust fittings for free of charge in the course of guarantee period of time

two. Provide fittings to seller with products

3. Download databases for free at any time

Your EPTT is Our EPT!!!

in Barnaul Russian Federation sales price shop near me near me shop factory supplier Ce Certificate Hydraulic Low Profile Hexagon Torque Wrenches for Petroleum Industry Tools manufacturer best Cost Custom Cheap wholesaler

Hangzhou EPG Co.,Ltd. , was launched in November, 1997. With its five wholly owned subsidiaries. In addition, all our generation processes are in compliance with ISO9002 standards. we offer you a single-stop remedy for the purchase of mechanical power transmission products in China. Minimal profile hexagon torque wrenches for petroleum sector equipment

Product Attributes:

1. Al-Ti alloy integrated EPTT has high energy, high tenacity with ligEPTT excess weight.

two. The 360 ordm times180 ordm rotating oil link has no limitation in utilised room and is handy to be operated.

3. The actuating shaft is introduced by torque and can rapidly swap among screwing up and dismantling.

4. The EPT piston and EPTT head have a little shape, compact framework and small procedure radius.

5. The nut rotation angle in one operation is big and the EPT piston has a rapid return stroke. The function performance is large.

six. The reactive pressure is on 1 straigEPTT line, which can reduce the interior torque abrasion.

seven. The continuous torque output supplies the substantial precision for wrench in the EPTT working procedure.

8. The routine maintenance is basic and does not need the EPTT resources.

9. The precise ratchet wheel is utilised in the inside of the wrench, with the precision up to plusmn3%.

| MHW Series Torque Conversion Chart | |||||||||||

| Moedel NO. | MHW-two | MHW-4 | MHW-8 | MHW-fourteen | MHW-30 | ||||||

| Screw Dimension | fifteen-fifty five | sixty | 34-sixty five | 70-eighty | 41-ninety five | a hundred-one zero five | 50-117 | a hundred and ten-one hundred fifty five | a hundred and sixty-a hundred seventy five | ||

| Mpa | bar | psi | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m |

| 7 | 70 | 1015 | 232 | 241 | 585 | 647 | 1094 | 1177 | 1852 | 4188 | 4459 |

| 8 | 80 | 1160 | 265 | 275 | 669 | 739 | 1250 | 1345 | 2117 | 4786 | 5096 |

| 9 | ninety | 1305 | 299 | 310 | 752 | 832 | 1407 | 1513 | 2381 | 5385 | 5733 |

| 10 | one hundred | 1450 | 332 | 344 | 836 | 924 | 1563 | 1682 | 2646 | 5983 | 6370 |

| 11 | 110 | 1595 | 365 | 379 | 920 | 1017 | 1719 | 1850 | 2910 | 6581 | 7007 |

| 12 | one hundred twenty | 1740 | 398 | 413 | 1003 | 1109 | 1876 | 2018 | 3175 | 7180 | 7644 |

| 13 | one hundred thirty | 1885 | 432 | 448 | 1087 | 1202 | 2032 | 2186 | 3440 | 7778 | 8281 |

| fourteen | one hundred forty | 2030 | 465 | 482 | 1171 | 1294 | 2188 | 2354 | 3704 | 8376 | 8918 |

| 15 | 150 | 2175 | 498 | 517 | 1255 | 1387 | 2344 | 2523 | 3969 | 8975 | 9555 |

| sixteen | one hundred sixty | 2320 | 531 | 551 | 1338 | 1479 | 2501 | 2691 | 4233 | 9573 | 10192 |

| seventeen | a hundred and seventy | 2465 | 565 | 586 | 1422 | 1572 | 2657 | 2859 | 4498 | 10171 | 10829 |

| eighteen | 180 | 2610 | 598 | 620 | 1506 | 1664 | 2813 | 3571 | 4762 | 10769 | 11467 |

| 19 | a hundred ninety | 2755 | 631 | 655 | 1589 | 1757 | 2970 | 3195 | 5571 | 11368 | 12104 |

| twenty | 200 | 2900 | 665 | 689 | 1673 | 1849 | 3126 | 3364 | 5292 | 11966 | 12741 |

| 21 | 210 | 3045 | 698 | 724 | 1757 | 1942 | 3282 | 3532 | 5556 | 12564 | 13378 |

| 22 | 220 | 3190 | 731 | 758 | 1840 | 2043 | 3439 | 3700 | 5821 | 13163 | 14015 |

| 23 | 230 | 3335 | 764 | 793 | 1924 | 2127 | 3595 | 3868 | 6085 | 13761 | 14652 |

| 24 | 240 | 3480 | 798 | 827 | 2008 | 2219 | 3751 | 4037 | 6350 | 14359 | 15289 |

| twenty five | 250 | 3625 | 831 | 862 | 2092 | 2312 | 3907 | 4205 | 6615 | 14958 | 15926 |

| 26 | 260 | 3770 | 864 | 896 | 2175 | 2404 | 4064 | 4373 | 6879 | 15556 | 16563 |

| 27 | 270 | 3915 | 897 | 931 | 2259 | 2497 | 4220 | 4541 | 7144 | 16154 | 17200 |

| 28 | 280 | 4060 | 931 | 965 | 2343 | 2589 | 4376 | 4709 | 7408 | 16753 | 17837 |

| 29 | 290 | 4205 | 964 | one thousand | 2426 | 2682 | 4533 | 4878 | 7673 | 17351 | 18474 |

| 30 | three hundred | 4350 | 997 | 1034 | 2510 | 2774 | 4689 | 5046 | 7938 | 17949 | 19111 |

| 31 | 310 | 4495 | 1030 | 1069 | 2594 | 2867 | 4845 | 5214 | 8202 | 18548 | 19748 |

| 32 | 320 | 4640 | 1064 | 1103 | 2677 | 2959 | 5002 | 5382 | 8467 | 19146 | 20385 |

| 33 | 330 | 4785 | 1097 | 1138 | 2761 | 3052 | 5158 | 5550 | 8731 | 19744 | 21571 |

| 34 | 340 | 4930 | 1130 | 1172 | 2845 | 3144 | 5314 | 5719 | 8996 | 20343 | 21659 |

| 35 | 350 | 5075 | 1164 | 1207 | 2929 | 3237 | 5470 | 5887 | 9260 | 20941 | 22296 |

| 36 | 360 | 5220 | 1197 | 1241 | 3012 | 3329 | 5627 | 6055 | 9525 | 21539 | 22933 |

| 37 | 370 | 5365 | 1230 | 1276 | 3096 | 3422 | 5783 | 6223 | 9790 | 22138 | 23570 |

| 38 | 380 | 5510 | 1263 | 1310 | 3180 | 3514 | 5939 | 6391 | 10054 | 22736 | 24207 |

| 39 | 390 | 5655 | 1297 | 1345 | 3263 | 3607 | 6096 | 6560 | 1571 | 23334 | 24845 |

| 40 | 400 | 5800 | 1330 | 1379 | 3347 | 3699 | 6252 | 6728 | 10583 | 23932 | 25482 |

| forty one | 410 | 5945 | 1363 | 1414 | 3431 | 3792 | 6408 | 6896 | 10848 | 24531 | 26119 |

| forty two | 420 | 6090 | 1396 | 1448 | 3514 | 3884 | 6565 | 7064 | 11113 | 25129 | 26756 |

| forty three | 430 | 6235 | 1430 | 1483 | 3598 | 3977 | 6721 | 7232 | 11377 | 25727 | 27393 |

| 44 | 440 | 6380 | 1463 | 1517 | 3682 | 4069 | 6877 | 7401 | 11642 | 26326 | 28030 |

| 45 | 450 | 6525 | 1496 | 1552 | 3766 | 4162 | 7033 | 7569 | 11906 | 26924 | 28667 |

| forty six | 460 | 6670 | 1530 | 1586 | 3849 | 4254 | 7190 | 7737 | 12171 | 27522 | 29304 |

| forty seven | 470 | 6815 | 1563 | 1621 | 3933 | 4347 | 9346 | 7905 | 12435 | 28121 | 29941 |

| forty eight | 480 | 6960 | 1596 | 1655 | 4017 | 4439 | 7502 | 8073 | 12700 | 28719 | 30578 |

| forty nine | 490 | 7105 | 1629 | 1690 | 4100 | 4532 | 7659 | 8242 | 12965 | 29317 | 31215 |

| fifty | five hundred | 7250 | 1663 | 1724 | 4184 | 4624 | 7815 | 8410 | 13229 | 29916 | 31852 |

| fifty one | 510 | 7395 | 1696 | 1759 | 4268 | 4717 | 7971 | 8578 | 13494 | 3571 | 32489 |

| fifty two | 520 | 7540 | 1729 | 1793 | 4351 | 4809 | 8128 | 8746 | 13758 | 31112 | 33126 |

| fifty three | 530 | 7685 | 1762 | 1828 | 4435 | 4902 | 8284 | 8914 | 14571 | 31711 | 33763 |

| 54 | 540 | 7830 | 1796 | 1862 | 4519 | 4994 | 8440 | 9083 | 14288 | 32309 | 34400 |

| fifty five | 550 | 7975 | 1829 | 1897 | 4603 | 5087 | 8596 | 9251 | 14552 | 32907 | 35037 |

| 56 | 560 | 8120 | 1862 | 1931 | 4686 | 5179 | 8753 | 9419 | 14817 | 33506 | 35674 |

| 57 | 570 | 8265 | 1895 | 1966 | 4770 | 5272 | 8909 | 9587 | 15081 | 34104 | 36311 |

| fifty eight | 580 | 8410 | 1929 | 2000 | 4854 | 5364 | 9065 | 9756 | 15346 | 34702 | 36948 |

| 59 | 590 | 8555 | 1962 | 2035 | 4937 | 5457 | 9222 | 9924 | 15611 | 35301 | 37585 |

| sixty | 600 | 8700 | 1995 | 2069 | 5571 | 5549 | 9378 | 10092 | 15875 | 35899 | 38223 |

| sixty one | 610 | 8845 | 2571 | 2104 | 5105 | 5642 | 9534 | 10260 | 16140 | 36497 | 38860 |

| sixty two | 620 | 8990 | 2062 | 2138 | 5188 | 5734 | 9691 | 10428 | 16404 | 37095 | 39497 |

| sixty three | 630 | 9135 | 2095 | 2173 | 5272 | 5827 | 9847 | 1571 | 16669 | 37694 | 40134 |

| sixty four | 640 | 9280 | 2128 | 2207 | 5356 | 5919 | 10003 | 10765 | 16933 | 38292 | 4571 |

| sixty five | 650 | 9425 | 2162 | 2242 | 5440 | 6012 | 10159 | 1571 | 17198 | 38890 | 41408 |

| 66 | 660 | 9570 | 2195 | 2276 | 5523 | 6104 | 10316 | 11101 | 17463 | 39489 | 42045 |

| sixty seven | 670 | 9715 | 2228 | 2311 | 5607 | 6197 | 1571 | 11269 | 17727 | 40087 | 42682 |

| sixty eight | 680 | 9860 | 2261 | 2345 | 5691 | 6289 | 10628 | 11438 | 17992 | 40685 | 43319 |

| sixty nine | 690 | 10005 | 2295 | 2380 | 5774 | 6382 | 10785 | 11606 | 18256 | 41284 | 43956 |

| 70 | 700 | 10150 | 2328 | 2414 | 5858 | 6474 | 10941 | 11774 | 18521 | 41882 | 44593 |

in Mangalore India sales price shop near me near me shop factory supplier Light Weight Hydraulic Square Drive Wrenches Whith Ce Certificate manufacturer best Cost Custom Cheap wholesaler

The group is targeted on making all selection of normal roller chains and sprockets, gears & gearboxes, such as conveyor chain & sprockets , stainless metal chain, agricultural chain and has not just sold its products all in excess of china, but also sold much more than sixty five% items to oversees, like Europe, The us, South-east Asia, and it also has set up storage logistics in spots like Europe. we are confident to provide our consumers versatile and diversified solutions. makes certain the steadiness and consistency of the essential operate of elements. LigEPTT WeigEPTT EPT Sq. Generate Wrenches

Merchandise Attributes:

1. Al-Ti alloy built-in EPTT has high energy, higher tenacity with ligEPTT fat.

2. The 360 ordm times180 ordm rotating oil link has no limitation in utilised area and is hassle-free to be operated.

3. The actuating shaft is released by torque and can quickly switch between screwing up and dismantling.

4. The EPT piston and EPTT head have a little shape, compact construction and tiny operation radius.

5. The nut rotation angle in solitary operation is massive and the EPT piston has a quick return stroke. The work effectiveness is high.

six. The reactive power is on a single straigEPTT line, which can decrease the inner torque abrasion.

7. The continuous torque output offers the higher precision for wrench in the EPTT functioning procedure.

eight. The routine maintenance is simple and does not require the EPTT instruments.

9. The specific ratchet wheel is used in the inside of of the wrench, with the precision up to plusmn3%.

| MDW Series Torque Conversion Chart | |||||||||||||

| Model No. | MDW-07 | MDW-1 | MDW-three | MDW-5 | MDW-8 | MDW-ten | MDW-fifteen | MDW-twenty | MDW-twenty five | MDW-35 | MDW-50 | ||

| Mpa | bar | psi | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m |

| 7 | 70 | 1015 | 112 | 183 | 451 | 752 | 1078 | 1551 | 2063 | 2666 | 3472 | 4866 | 7200 |

| eight | eighty | 1160 | 128 | 209 | 515 | 860 | 1232 | 1773 | 2357 | 3047 | 3968 | 5561 | 8229 |

| 9 | ninety | 1305 | one hundred forty four | 236 | 580 | 967 | 1386 | 1994 | 2652 | 3428 | 4464 | 6256 | 9257 |

| ten | 100 | 1450 | one hundred sixty | 262 | 644 | 1075 | 1540 | 2216 | 2946 | 3809 | 4960 | 6952 | 15716 |

| 11 | one hundred ten | 1595 | 176 | 288 | 709 | 1182 | 1694 | 2438 | 3241 | 4190 | 5456 | 7647 | 11314 |

| 12 | a hundred and twenty | 1740 | 192 | 314 | 773 | 1290 | 1848 | 2659 | 3536 | 4571 | 5952 | 8342 | 12343 |

| thirteen | a hundred thirty | 1885 | 208 | 341 | 838 | 1397 | 2002 | 2881 | 3831 | 4952 | 6448 | 9037 | 13371 |

| fourteen | 140 | 2030 | 224 | 367 | 902 | 1505 | 2156 | 3103 | 4125 | 5332 | 6945 | 9733 | 14400 |

| 15 | one hundred fifty | 2175 | 240 | 393 | 967 | 1612 | 2310 | 3324 | 4420 | 5713 | 7441 | 10428 | 15429 |

| 16 | a hundred and sixty | 2320 | 256 | 419 | 1031 | 1720 | 2464 | 3546 | 4714 | 6094 | 7937 | 11123 | 16457 |

| 17 | one hundred seventy | 2465 | 272 | 446 | 1096 | 1828 | 2618 | 3768 | 5009 | 6475 | 8433 | 11818 | 17486 |

| eighteen | a hundred and eighty | 2610 | 288 | 472 | 1160 | 1935 | 2772 | 3989 | 5304 | 6856 | 8929 | 12514 | 18514 |

| 19 | one hundred ninety | 2755 | 304 | 498 | 1225 | 2043 | 2926 | 4211 | 5599 | 7237 | 9425 | 13209 | 19543 |

| 20 | two hundred | 2900 | 320 | 524 | 1289 | 2150 | 3080 | 4433 | 5893 | 7618 | 9921 | 13904 | 2571 |

| 21 | 210 | 3045 | 336 | 551 | 1353 | 2258 | 3234 | 4654 | 6188 | 7999 | 1571 | 14599 | 21600 |

| 22 | 220 | 3190 | 352 | 577 | 1418 | 2365 | 3388 | 4876 | 6482 | 8380 | 1571 | 15295 | 22629 |

| 23 | 230 | 3335 | 368 | 603 | 1482 | 2473 | 3542 | 5098 | 6777 | 8761 | 11409 | 15990 | 23657 |

| 24 | 240 | 3480 | 384 | 629 | 1547 | 2580 | 3696 | 5319 | 7072 | 9142 | 11905 | 16685 | 24686 |

| 25 | 250 | 3625 | 400 | 656 | 1611 | 2688 | 3850 | 5541 | 7367 | 9523 | 12401 | 17380 | 25714 |

| 26 | 260 | 3770 | 416 | 682 | 1676 | 2796 | 4004 | 5763 | 7661 | 9903 | 12898 | 18076 | 26743 |

| 27 | 270 | 3915 | 432 | 708 | 1740 | 2903 | 4158 | 5984 | 7956 | 15714 | 13394 | 18771 | 27771 |

| 28 | 280 | 4060 | 448 | 734 | 1805 | 3011 | 4312 | 6206 | 8250 | 10665 | 13890 | 19466 | 28800 |

| 29 | 290 | 4205 | 464 | 761 | 1869 | 3118 | 4466 | 6428 | 8545 | 11046 | 14386 | 20161 | 29829 |

| 30 | 300 | 4350 | 480 | 787 | 1934 | 3226 | 4620 | 6649 | 8840 | 11427 | 14882 | 2571 | 30857 |

| 31 | 310 | 4495 | 496 | 813 | 1998 | 3333 | 4774 | 6871 | 9135 | 11808 | 15378 | 21552 | 31886 |

| 32 | 320 | 4640 | 512 | 839 | 2063 | 3441 | 4928 | 7093 | 9429 | 12189 | 15874 | 22247 | 32914 |

| 33 | 330 | 4785 | 528 | 866 | 2127 | 3548 | 5082 | 7314 | 9724 | 12570 | 16370 | 22942 | 33943 |

| 34 | 340 | 4930 | 544 | 892 | 2191 | 3656 | 5236 | 7536 | 10018 | 12951 | 16866 | 23637 | 34971 |

| 35 | 350 | 5075 | 560 | 918 | 2256 | 3764 | 5390 | 7758 | 1571 | 13332 | 17362 | 24333 | 36000 |

| 36 | 360 | 5220 | 576 | 944 | 2320 | 3871 | 5544 | 7979 | 10608 | 13713 | 17858 | 25571 | 37571 |

| 37 | 370 | 5365 | 592 | 971 | 2385 | 3979 | 5698 | 8201 | 10903 | 14094 | 18354 | 25723 | 38057 |

| 38 | 380 | 5510 | 608 | 997 | 2449 | 4086 | 5852 | 8423 | 11197 | 14475 | 18850 | 26418 | 39086 |

| 39 | 390 | 5655 | 624 | 1571 | 2514 | 4194 | 6006 | 8644 | 11492 | 14855 | 19347 | 27114 | 40114 |

| forty | four hundred | 5800 | 640 | 1049 | 2578 | 4301 | 6160 | 8866 | 11786 | 15236 | 19843 | 27809 | 41143 |

| 41 | 410 | 5945 | 656 | 1076 | 2643 | 4409 | 6314 | 9088 | 12082 | 15617 | 20339 | 28504 | 42171 |

| 42 | 420 | 6090 | 672 | 1102 | 2707 | 4516 | 6468 | 9309 | 12376 | 15998 | 2571 | 29199 | 43200 |

| 43 | 430 | 6235 | 688 | 1128 | 2772 | 4624 | 6622 | 9531 | 12671 | 16379 | 21331 | 29895 | 44229 |

| 44 | 440 | 6380 | 704 | 1154 | 2836 | 4732 | 6776 | 9753 | 12965 | 16760 | 21827 | 30590 | 45257 |

| 45 | 450 | 6525 | 720 | 1181 | 2900 | 4839 | 6930 | 9974 | 13260 | 17141 | 22323 | 31285 | 46286 |

| 46 | 460 | 6670 | 736 | 1207 | 2965 | 4947 | 7084 | 10196 | 13554 | 17522 | 22819 | 31980 | 47314 |

| forty seven | 470 | 6815 | 752 | 1233 | 3571 | 5054 | 7238 | 1571 | 13850 | 17903 | 23315 | 32676 | 48343 |

| 48 | 480 | 6960 | 768 | 1259 | 3094 | 5162 | 7392 | 10639 | 14144 | 18284 | 23811 | 33371 | 49371 |

| 49 | 490 | 7105 | 784 | 1286 | 3158 | 5269 | 7546 | 10861 | 14439 | 18665 | 24307 | 34066 | 50400 |

| 50 | 500 | 7250 | 800 | 1312 | 3223 | 5377 | 7700 | 11083 | 14733 | 19046 | 24803 | 34761 | 51429 |

| fifty one | 510 | 7395 | 816 | 1338 | 3287 | 5484 | 7854 | 11304 | 15571 | 19427 | 25299 | 35456 | 52457 |

| fifty two | 520 | 7540 | 832 | 1364 | 3352 | 5592 | 8008 | 11526 | 15322 | 19807 | 25796 | 36152 | 53486 |

| fifty three | 530 | 7685 | 848 | 1391 | 3416 | 5700 | 8162 | 11748 | 15618 | 20188 | 26292 | 36847 | 54514 |

| 54 | 540 | 7830 | 864 | 1417 | 3481 | 5807 | 8316 | 11969 | 15912 | 20569 | 26788 | 37542 | 55543 |

| 55 | 550 | 7975 | 880 | 1443 | 3545 | 5915 | 8470 | 12191 | 16207 | 20950 | 27284 | 38237 | 56571 |

| 56 | 560 | 8120 | 896 | 1469 | 3610 | 6571 | 8624 | 12413 | 16501 | 21331 | 27780 | 38933 | 57600 |

| 57 | 570 | 8265 | 912 | 1496 | 3674 | 6130 | 8778 | 12634 | 16796 | 21712 | 28276 | 39628 | 58629 |

| 58 | 580 | 8410 | 928 | 1522 | 3737 | 6237 | 8932 | 12856 | 17090 | 22093 | 28772 | 40323 | 59657 |

| fifty nine | 590 | 8555 | 944 | 1548 | 3803 | 6345 | 9086 | 13078 | 17386 | 22474 | 29268 | 41018 | 60686 |

| 60 | 600 | 8700 | 960 | 1574 | 3867 | 6452 | 9240 | 13299 | 17680 | 22855 | 29764 | 41714 | 61714 |

| sixty one | 610 | 8845 | 976 | 1601 | 3932 | 6560 | 9394 | 13521 | 17975 | 23236 | 30260 | 42409 | 62743 |

| sixty two | 620 | 8990 | 992 | 1627 | 3996 | 6668 | 9548 | 13743 | 18269 | 23617 | 3571 | 43104 | 63771 |

| sixty three | 630 | 9135 | 1008 | 1653 | 4061 | 6775 | 9702 | 13964 | 18564 | 23998 | 31252 | 43799 | 64800 |

| 64 | 640 | 9280 | 1571 | 1679 | 4125 | 6883 | 9856 | 14186 | 18858 | 24378 | 31749 | 44495 | 65829 |

| sixty five | 650 | 9425 | 1040 | 1706 | 4190 | 6990 | 1571 | 14408 | 19154 | 24759 | 32245 | 45190 | 66857 |

| sixty six | 660 | 9570 | 1056 | 1732 | 4254 | 7098 | 10164 | 14629 | 19448 | 25140 | 32741 | 45885 | 67886 |

| sixty seven | 670 | 9715 | 1072 | 1758 | 4319 | 7205 | 10318 | 14851 | 19743 | 25521 | 33237 | 46580 | 68914 |

| sixty eight | 680 | 9860 | 1088 | 1784 | 4383 | 7313 | 1571 | 15073 | 20037 | 25902 | 33733 | 47276 | 69943 |

| sixty nine | 690 | 10005 | 1104 | 1811 | 4448 | 7420 | 10626 | 15294 | 20332 | 26283 | 34229 | 47971 | 7571 |

| 70 | seven hundred | 10150 | 1120 | 1837 | 4512 | 7528 | 10780 | 15516 | 20627 | 26664 | 34725 | 48666 | 72000 |

in Bien Hoa Viet Nam sales price shop near me near me shop factory supplier Square Drive Corrosion Resistant Hydraulic Torque Wrench manufacturer best Cost Custom Cheap wholesaler

Our principal items are Needle Roller bearings, Cylindrical Roller Bearings, Rod finish Bearings, Spherical simple bearings, Keep track of roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, Water Pump Bearings, SNR Automobile Bearings and all types of Spherical Bearings. Our AdvantagesProducts Huge quantity in Inventory, No MOQ required We comply with all the international expectations, this kind of as ISO9001 and TS16949 expectations. In 2008, it was awarded with “Countrywide Export Commodity Inspection-free of charge Business”. Square Generate Corrosion Resistant EPT Torque Wrench

Solution Attributes:

one. Al-Ti alloy built-in EPTT has higher strength, large tenacity with ligEPTT fat.

2. The 360 ordm times180 ordm rotating oil relationship has no limitation in utilized place and is hassle-free to be operated.

3. The actuating shaft is unveiled by torque and can quickly swap among screwing up and dismantling.

four. The EPT piston and EPTT head have a tiny condition, compact construction and modest operation radius.

five. The nut rotation angle in solitary procedure is large and the EPT piston has a swift return stroke. The perform efficiency is substantial.

six. The reactive force is on one particular straigEPTT line, which can decrease the internal torque abrasion.

7. The consistent torque output offers the high precision for wrench in the EPTT operating process.

8. The upkeep is straightforward and does not need to have the EPTT instruments.

9. The specific ratchet wheel is employed in the inside of the wrench, with the precision up to plusmn3%.

MDW Series TORQUE CEPTRT

| MDW Collection Torque Conversion Chart | |||||||||||||

| Design No. | MDW-07 | MDW-1 | MDW-3 | MDW-5 | MDW-8 | MDW-10 | MDW-fifteen | MDW-20 | MDW-25 | MDW-35 | MDW-50 | ||

| Mpa | bar | psi | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m | N.m |

| seven | 70 | 1015 | 112 | 183 | 451 | 752 | 1078 | 1551 | 2063 | 2666 | 3472 | 4866 | 7200 |

| eight | eighty | 1160 | 128 | 209 | 515 | 860 | 1232 | 1773 | 2357 | 3047 | 3968 | 5561 | 8229 |

| 9 | 90 | 1305 | 144 | 236 | 580 | 967 | 1386 | 1994 | 2652 | 3428 | 4464 | 6256 | 9257 |

| ten | one hundred | 1450 | a hundred and sixty | 262 | 644 | 1075 | 1540 | 2216 | 2946 | 3809 | 4960 | 6952 | 15716 |

| 11 | one hundred ten | 1595 | 176 | 288 | 709 | 1182 | 1694 | 2438 | 3241 | 4190 | 5456 | 7647 | 11314 |

| twelve | a hundred and twenty | 1740 | 192 | 314 | 773 | 1290 | 1848 | 2659 | 3536 | 4571 | 5952 | 8342 | 12343 |

| 13 | one hundred thirty | 1885 | 208 | 341 | 838 | 1397 | 2002 | 2881 | 3831 | 4952 | 6448 | 9037 | 13371 |

| 14 | one hundred forty | 2030 | 224 | 367 | 902 | 1505 | 2156 | 3103 | 4125 | 5332 | 6945 | 9733 | 14400 |

| fifteen | a hundred and fifty | 2175 | 240 | 393 | 967 | 1612 | 2310 | 3324 | 4420 | 5713 | 7441 | 10428 | 15429 |

| sixteen | one hundred sixty | 2320 | 256 | 419 | 1031 | 1720 | 2464 | 3546 | 4714 | 6094 | 7937 | 11123 | 16457 |

| seventeen | 170 | 2465 | 272 | 446 | 1096 | 1828 | 2618 | 3768 | 5009 | 6475 | 8433 | 11818 | 17486 |

| 18 | 180 | 2610 | 288 | 472 | 1160 | 1935 | 2772 | 3989 | 5304 | 6856 | 8929 | 12514 | 18514 |

| 19 | a hundred ninety | 2755 | 304 | 498 | 1225 | 2043 | 2926 | 4211 | 5599 | 7237 | 9425 | 13209 | 19543 |

| 20 | 200 | 2900 | 320 | 524 | 1289 | 2150 | 3080 | 4433 | 5893 | 7618 | 9921 | 13904 | 2571 |

| 21 | 210 | 3045 | 336 | 551 | 1353 | 2258 | 3234 | 4654 | 6188 | 7999 | 1571 | 14599 | 21600 |

| 22 | 220 | 3190 | 352 | 577 | 1418 | 2365 | 3388 | 4876 | 6482 | 8380 | 1571 | 15295 | 22629 |

| 23 | 230 | 3335 | 368 | 603 | 1482 | 2473 | 3542 | 5098 | 6777 | 8761 | 11409 | 15990 | 23657 |

| 24 | 240 | 3480 | 384 | 629 | 1547 | 2580 | 3696 | 5319 | 7072 | 9142 | 11905 | 16685 | 24686 |

| twenty five | 250 | 3625 | four hundred | 656 | 1611 | 2688 | 3850 | 5541 | 7367 | 9523 | 12401 | 17380 | 25714 |

| 26 | 260 | 3770 | 416 | 682 | 1676 | 2796 | 4004 | 5763 | 7661 | 9903 | 12898 | 18076 | 26743 |

| 27 | 270 | 3915 | 432 | 708 | 1740 | 2903 | 4158 | 5984 | 7956 | 15714 | 13394 | 18771 | 27771 |

| 28 | 280 | 4060 | 448 | 734 | 1805 | 3011 | 4312 | 6206 | 8250 | 10665 | 13890 | 19466 | 28800 |

| 29 | 290 | 4205 | 464 | 761 | 1869 | 3118 | 4466 | 6428 | 8545 | 11046 | 14386 | 20161 | 29829 |

| 30 | 300 | 4350 | 480 | 787 | 1934 | 3226 | 4620 | 6649 | 8840 | 11427 | 14882 | 2571 | 30857 |

| 31 | 310 | 4495 | 496 | 813 | 1998 | 3333 | 4774 | 6871 | 9135 | 11808 | 15378 | 21552 | 31886 |

| 32 | 320 | 4640 | 512 | 839 | 2063 | 3441 | 4928 | 7093 | 9429 | 12189 | 15874 | 22247 | 32914 |

| 33 | 330 | 4785 | 528 | 866 | 2127 | 3548 | 5082 | 7314 | 9724 | 12570 | 16370 | 22942 | 33943 |

| 34 | 340 | 4930 | 544 | 892 | 2191 | 3656 | 5236 | 7536 | 10018 | 12951 | 16866 | 23637 | 34971 |

| 35 | 350 | 5075 | 560 | 918 | 2256 | 3764 | 5390 | 7758 | 1571 | 13332 | 17362 | 24333 | 36000 |

| 36 | 360 | 5220 | 576 | 944 | 2320 | 3871 | 5544 | 7979 | 10608 | 13713 | 17858 | 25571 | 37571 |

| 37 | 370 | 5365 | 592 | 971 | 2385 | 3979 | 5698 | 8201 | 10903 | 14094 | 18354 | 25723 | 38057 |

| 38 | 380 | 5510 | 608 | 997 | 2449 | 4086 | 5852 | 8423 | 11197 | 14475 | 18850 | 26418 | 39086 |

| 39 | 390 | 5655 | 624 | 1571 | 2514 | 4194 | 6006 | 8644 | 11492 | 14855 | 19347 | 27114 | 40114 |

| forty | four hundred | 5800 | 640 | 1049 | 2578 | 4301 | 6160 | 8866 | 11786 | 15236 | 19843 | 27809 | 41143 |

| 41 | 410 | 5945 | 656 | 1076 | 2643 | 4409 | 6314 | 9088 | 12082 | 15617 | 20339 | 28504 | 42171 |

| forty two | 420 | 6090 | 672 | 1102 | 2707 | 4516 | 6468 | 9309 | 12376 | 15998 | 2571 | 29199 | 43200 |

| forty three | 430 | 6235 | 688 | 1128 | 2772 | 4624 | 6622 | 9531 | 12671 | 16379 | 21331 | 29895 | 44229 |

| 44 | 440 | 6380 | 704 | 1154 | 2836 | 4732 | 6776 | 9753 | 12965 | 16760 | 21827 | 30590 | 45257 |

| forty five | 450 | 6525 | 720 | 1181 | 2900 | 4839 | 6930 | 9974 | 13260 | 17141 | 22323 | 31285 | 46286 |

| 46 | 460 | 6670 | 736 | 1207 | 2965 | 4947 | 7084 | 10196 | 13554 | 17522 | 22819 | 31980 | 47314 |

| 47 | 470 | 6815 | 752 | 1233 | 3571 | 5054 | 7238 | 1571 | 13850 | 17903 | 23315 | 32676 | 48343 |

| forty eight | 480 | 6960 | 768 | 1259 | 3094 | 5162 | 7392 | 10639 | 14144 | 18284 | 23811 | 33371 | 49371 |

| 49 | 490 | 7105 | 784 | 1286 | 3158 | 5269 | 7546 | 10861 | 14439 | 18665 | 24307 | 34066 | 50400 |

| 50 | 500 | 7250 | 800 | 1312 | 3223 | 5377 | 7700 | 11083 | 14733 | 19046 | 24803 | 34761 | 51429 |

| fifty one | 510 | 7395 | 816 | 1338 | 3287 | 5484 | 7854 | 11304 | 15571 | 19427 | 25299 | 35456 | 52457 |

| fifty two | 520 | 7540 | 832 | 1364 | 3352 | 5592 | 8008 | 11526 | 15322 | 19807 | 25796 | 36152 | 53486 |

| 53 | 530 | 7685 | 848 | 1391 | 3416 | 5700 | 8162 | 11748 | 15618 | 20188 | 26292 | 36847 | 54514 |

| fifty four | 540 | 7830 | 864 | 1417 | 3481 | 5807 | 8316 | 11969 | 15912 | 20569 | 26788 | 37542 | 55543 |

| 55 | 550 | 7975 | 880 | 1443 | 3545 | 5915 | 8470 | 12191 | 16207 | 20950 | 27284 | 38237 | 56571 |

| 56 | 560 | 8120 | 896 | 1469 | 3610 | 6571 | 8624 | 12413 | 16501 | 21331 | 27780 | 38933 | 57600 |

| fifty seven | 570 | 8265 | 912 | 1496 | 3674 | 6130 | 8778 | 12634 | 16796 | 21712 | 28276 | 39628 | 58629 |

| fifty eight | 580 | 8410 | 928 | 1522 | 3737 | 6237 | 8932 | 12856 | 17090 | 22093 | 28772 | 40323 | 59657 |

| fifty nine | 590 | 8555 | 944 | 1548 | 3803 | 6345 | 9086 | 13078 | 17386 | 22474 | 29268 | 41018 | 60686 |

| sixty | 600 | 8700 | 960 | 1574 | 3867 | 6452 | 9240 | 13299 | 17680 | 22855 | 29764 | 41714 | 61714 |

| sixty one | 610 | 8845 | 976 | 1601 | 3932 | 6560 | 9394 | 13521 | 17975 | 23236 | 30260 | 42409 | 62743 |

| sixty two | 620 | 8990 | 992 | 1627 | 3996 | 6668 | 9548 | 13743 | 18269 | 23617 | 3571 | 43104 | 63771 |

| 63 | 630 | 9135 | 1008 | 1653 | 4061 | 6775 | 9702 | 13964 | 18564 | 23998 | 31252 | 43799 | 64800 |

| sixty four | 640 | 9280 | 1571 | 1679 | 4125 | 6883 | 9856 | 14186 | 18858 | 24378 | 31749 | 44495 | 65829 |

| sixty five | 650 | 9425 | 1040 | 1706 | 4190 | 6990 | 1571 | 14408 | 19154 | 24759 | 32245 | 45190 | 66857 |

| 66 | 660 | 9570 | 1056 | 1732 | 4254 | 7098 | 10164 | 14629 | 19448 | 25140 | 32741 | 45885 | 67886 |

| sixty seven | 670 | 9715 | 1072 | 1758 | 4319 | 7205 | 10318 | 14851 | 19743 | 25521 | 33237 | 46580 | 68914 |

| 68 | 680 | 9860 | 1088 | 1784 | 4383 | 7313 | 1571 | 15073 | 20037 | 25902 | 33733 | 47276 | 69943 |

| 69 | 690 | 10005 | 1104 | 1811 | 4448 | 7420 | 10626 | 15294 | 20332 | 26283 | 34229 | 47971 | 7571 |

| 70 | seven-hundred | 10150 | 1120 | 1837 | 4512 | 7528 | 10780 | 15516 | 20627 | 26664 | 34725 | 48666 | 72000 |

Application:

Get in touch with person: Lily EPTTg

Cellular: 137 3819 0616

China manufacturer & factory supplier for china in Guatemala City Guatemala supplier parker hydraulic motorsmotors hydraulichydraulic motor Eaton T series With high quality best price & service

EPG significant manufacturer and supplier of ball bearings and energy transmission equipment. Because it is commencing in 1992, EPG has grown into 1 of the top suppliers in the sector. Key variables that have contributed to our development is our dedication to the fundamentals of progressive design and style, competitive pricing, exceptional customer provider, and merchandise availability.The new products consist of a collection of higher-tech and large top quality chains and sprockets and gears, this sort of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator stage-chains, substantial-speed tooth chains, timing chains, self-lubrication chains, between which have sort high speed tooth chain for car branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Specifics

- Right after Guarantee Support:

-

Online video specialized assist

- Nearby Service Location:

-

Egypt

- Showroom Area:

-

Egypt

- Sort:

-

elements

- Soon after-product sales Services Supplied:

-

Movie specialized assistance

Supply Ability

- Offer Potential:

- 500000 Piece/Parts for every 12 months

Packaging & Delivery

In our company we are mindful of the significance of the users’ basic safety. That’s why our PTO’s are developed in accordance to legal laws and European directives and bear the CE indicator. A crucial factor for basic safety assurance is the accession in the products’ development stage. By all means, the users’ expertise about the appropriate use of a PTO push shaft is important. This implies, that each and every users’ duty is to read through and stick to the safety recommendations.

- Packaging Particulars

- Carton or Plywood scenario or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

“EPG” brand name rotocultivator ploughshares in T.S. total lines made in our manufacturing unit have been analyzed and appraised by the Ministry of Agriculture and have acquired the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

-

Guide Time

: -

Amount(Baggage) 1 – 50 >50 Est. Time(times) 15 To be negotiated

On the internet Customization

| Variety | ZBM3/80 | ZBM3/one hundred | ZBM3/one hundred twenty five | ZBM4/one hundred sixty | ZBM3/200 | ZBM4/250 | ZBM4/320 | ZBM4/four hundred |

| Displcement (ml/r) |

eighty.5 | 100.five | 126.three | 158.8 | 200.eight | 252.two | 317.5 | 401.6 |

| Max.Stress. Drop (Mpa) |

16 | 16 | 16 | 16 | 16 | 16 | 16 | 12.five |

| Max. torque (N.Mm) |

156 | 193 | 243 | 307 | 387 | 513 | 613 | 685 |

| Max. Pace (cont.)(r/min) |

620 | 500 | four hundred | five hundred | four hundred | 320 | 250 | two hundred |

| Releasing strain (Mpa) | 2.6 | two.6 | 2.six | two.6 | 2.six | 2.six | two.six | two.six |

| Linked motor | BM3-eighty | BM3-a hundred | BM3-125 | BM4-a hundred and sixty | BM4-200 | BM4-250 | BM4-320 | BM4-four hundred |

| brake torque (N.m) |

245 | 245 | 245 | 590 | 824 | 824 | 824 | 824 |

| Weight(kg) | eighteen | 18 | eighteen | 37 | 37 | 37 | 37 | 38 |

Ship made in China – replacement parts – in Bellary India Winches Deck Equipment OEM Hydraulic Mooring Winch with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Ship Winches Deck Gear OEM EPT Mooring Winch

1.Generally, the set up of the windlass need to make certain that the 3 details of the anchor chain leading out (the anchor chain barrel, the chain controller and the sprocket) are in one line

two.Function load: refers to the pressure calculated at the outlet of the anchor chain wheel.

three.Overload pressure: the limited time overload potential needed by the windlass.

four.Common velocity: the speed at which two anchor chains are recovered when a few are in the h2o and are freely suspended.

5.Assist load: refers to the highest static load on the anchor chain that the anchor chain wheel brake ought to be in a position to bear.

| Model | Dian of chain wheel(mm) | Working load(kn) | Overhead pulling drive(kn) | Holding load(kn) | Nominal pace(m/min) | Warping load(kn) | |||

| AM2 | AM3 | AM2 | AM3 | AM2 | AM3 | ||||

| seventeen.5 | seventeen.5 | thirteen | fourteen.6 | 19.five | 21.nine | 80 | one hundred fifteen | nine | 8 |

| 19 | 19 | fifteen.three | seventeen.two | 23. | twenty five.eight | ninety five | a hundred thirty five | 9 | 10 |

| twenty | twenty | seventeen.9 | twenty. | 26.nine | thirty. | a hundred and ten | 157 | 9 | 10 |

| 22 | 22 | 20.six | 23. | thirty.nine | 34.five | 126 | one hundred eighty | nine | 15 |

| 24 | 24 | 24.five | 24.four | 36.eight | 41.one | 149 | 214 | 9 | twenty |

| 26 | 26 | 28.seven | 32.one | forty three.one | forty eight.two | one hundred seventy five | 150 | nine | 20 |

| 28 | 28 | 33.three | 37.2 | 50. | 55.8 | 202 | 289 | nine | twenty |

| 30 | 30 | 38.3 | forty two.eight | fifty seven.5 | 64.2 | 231 | 330 | 9 | 30 |

| 32 | 32 | 43.five | 48.six | 65.3 | 72.nine | 261 | 374 | 9 | 30 |

| 34 | 34 | forty nine.one | 54.9 | 73.seven | eighty two.4 | 294 | 421 | nine | 30 |

| 36 | 36 | fifty five.one | sixty one.6 | eighty two.seven | ninety two.four | 329 | 470 | nine | thirty |

| 38 | 38 | 61.four | sixty eight.nine | ninety two.1 | 103.4 | 365 | 522 | 9 | 40 |

| forty | forty | sixty eight | 76. | 102. | 114. | 402 | 576 | 9 | forty |

The windlass is a mechanical gadget for throwing, lifting and retracting the anchor. It is positioned at the bow of the ship.The roller on each sides of the sprocket wheel can be utilised for twisting and retracting ropes.Windlass can be divided into human windlass, electrical windlass and electrical hydraulic windlass according to various electricity.At current, the EPT windlass is largely electric powered hydraulic windlass and electric windlass

four.In buy to ship you a mo EPT suitble model we want validate the pursuing info.

1), what is the winch pulling capacity?

two),what is the winch wire rope length?

three),what is the wire rope diameters?

four)You require the winch with single or double drum?and for each drum pulling capability?

5),what is the winch working setting?

six),Are you need to have electricity pack?

if you have inquiry, p EPT contact me freely

The use of original equipment manufacturer’s (OEM) part figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our organization and the outlined substitution areas contained herein are not sponsored, approved, or manufactured by the OEM.

New made in China – replacement parts – 60 feet of chain link fence in Jerusalem Israel 16 Ton Hydraulic Pneumatic Tire Roller XP163 with ce certificate top quality low price

We – EPG Group the greatest Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For far more details: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

Furthermore, WE CAN Make Custom-made VARIATORS, GEARED MOTORS, Electric MOTORS AND OTHER HYDRAULIC Merchandise In accordance TO CUSTOMERS’ DRAWINGS.ISO With numerous years’ experience in these lines, we have been distinguished from other suppliers in China by our advantages in aggressive pricing, on-time supply, prompt responses, on-hand engineering support and good soon after-income providers. 9001:2000 & AS 9100B licensed custom company of roller chains. Requirements of roller chains incorporate .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. size, a hundred and eighty lbs. to 1529 lbs. tensile load capacity & .035 lbs. to .276 lbs. weight/ft. One facet of our application consulting is that we have been amassing and combining the encounter in chain and sprocket applications in numerous areas for many years. This is notably interesting for us every time clients method us with some exceeding and difficult specifications.

EPT sixteen ton EPT pneumatic tire roller XP163

XP163/XP203 tyre compactor is the landmark of 3 collection items designed on the basis of 2 sequence goods. It sales opportunities the advancement of Chinese tyre compactor because of to its substantial begin, large approach, high overall performance, and substantial quality. The device functions gorgeous appearance, driving ease and comfort, basic operation, outstanding performance, protection and reliability, and handy servicing. It can be applied in the design of asphalt street, base layer, hypo-base layer, and fill building. It is a required compact tools for street construction and water conservancy construction, especially for the high-grade highways.

Driving comfort

Roomy and vibrant taxi characteristics extensive look at and convenience. Equally-facet procedure can definitely keep away from rolling the suppress and the compacting blind corners.

Simple operation

There are two steering wheels, two seats, and two unbiased management systems for functions. The pace alter adopts the gearbox with synchronizer, with 3 forward gears and 2 reverse gears, which can respectively fulfill the requirements of compaction and internet site transfer, showcasing adaptable procedure and relaxed handfeel, and greatly minimizing the labor depth of the motorists.

EPT performance

Adopting the pneumatic tyre to compact the layer will not damage the compacted supplies. The compact efficiency can be enhanced by incorporating or decreasing the counterweight and modifying the inflation force of the tyres. Because of the kneading result created by the tyre’s elasticity, the materials displacement will be created in all directions, forming even dense area with out cracks, which can extend the service daily life of the highway. When the machine operates on tough highway, the entrance whee EPT swing system ensures the even floor strain, which can make the materia EPT be compacted evenly.

Protection and trustworthiness

The brake technique involves unexpected emergency brake and hand brake. The emergency brake adopts air more than oil shoe brake method, features durability and trustworthiness, making certain the safety functionality of the machine. The hand brake adopts diaphragm spring brake, it health supplements the foot brake and is restricted by the foot brake, showcasing protection and trustworthiness.

Reliability of drinking water circuit

The water sprinkling system of XP163/XP203 fulfills the requirements of diverse operating conditions, prolongs the support lifestyle of the h2o pump, and avoids halting perform thanks to the water circuit failures.

The optional oil sprinkle unit meets the customer’s personalized need, efficiently lowers the asphalt adhered to the tyres, and increases the doing work quality.

Energy conservation and environment protection

Minimal sounds supercharged diesel engine characteristics large efficiency, reputable high quality, and great inexpensive functionality, meeting the emission stHangZhourd of phase II.

Handy servicing

The motor protect is straightforward to open. The rear portion of the device adopts the go over plate composition which can be lifted. Lifting the water tank backward can facilitate the inspection, adjustment, and maintenance of the battery, drinking water pump system, and chains.

Specifications:

|

Kind |

Device |

XP163 |

|

Functioning excess weight |

kg |

11100 |

|

Max working weight |

kg |

16000 |

|

Journey Speed, Forward |

km/h |

4.2 , 8.2 , 17.4 |

|

Vacation Velocity, Reverse |

Km/h |

4.2, 8.2 |

|

Gradeability in idea |

% |

thirty |

|

Least outer turning radius |

mm |

7230 |

|

Min ground clearance |

mm |

250 |

|

Compacting width |

mm |

2055 |

|

Overlapping of front&rear tyre |

mm |

thirty |

|

Tire specification |

9.-12-20PR |

|

|

Amount of tyres |

four front & 5 rear |

|

|

Floor stress |

kPa |

200-four hundred |

|

Motor Design |

|

YC4A125Z |

|

Rated rotating velocity |

r/min |

2200 |

|

Rated electrical power |

kW |

ninety two |

|

Engine oil consumption |

g.kw/h |

≤230 |

|

Dimensions(LxWxH) |

mm |

4770x2210x3442 |

|

Fuel tank potential |

L |

130 |

|

EPT oil tank ability |

L |

sixty |

Machine Photographs: EPT sixteen ton EPT pneumatic tire roller XP163

The use of unique products manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating product use and compatibility. Our business and the detailed alternative elements contained herein are not sponsored, accepted, or created by the OEM.