Product Description

Introducing our Five-Axis CNC Machining Parts, perfect for precision machining needs. Made by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., these high-quality CNC parts are durable and reliable. Get efficient four-axis CNC parts for your industrial needs.

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | HangZhou, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Detailed Photos

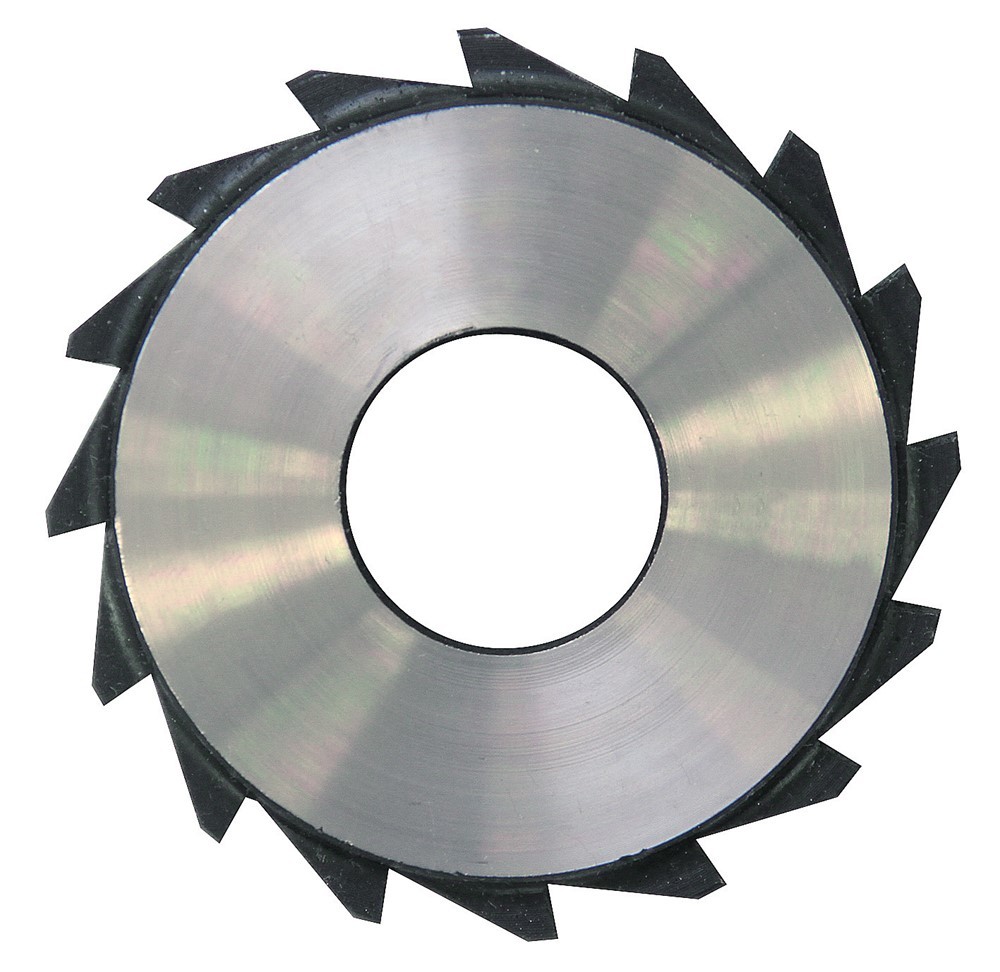

Explore our collection of high-quality CNC machining parts, including precision five-axis, four-axis, and milling parts. Our custom-made components are perfect for packing machines, ratchets, and carrier tape needle wheels. Trust HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for durable and reliable CNC parts.

Five-Axis CNC Machining Parts

Experience precision and quality with our Five-Axis CNC Machining Parts. Crafted by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., these parts are designed to elevate your machining needs to new heights.

Our CNC Machining Parts are meticulously processed using state-of-the-art technology. The mask machine knurling wheel, for example, undergoes a multi-step production process. It begins with CNC turning, which creates a rough blank. Then, our precision 5-axis CNC machines take over, ensuring every detail is flawlessly executed. Finally, a surface electroplating finish adds a touch of elegance.

With our Five-Axis Machining Parts, you can expect durability, reliability, and efficiency. They are perfect for a wide range of applications, including milling parts, packing machine parts, ratchet parts, and carrier tape needle wheel parts.

Choose our Custom Five-Axis Machining Parts for a tailored solution that meets your specific requirements. We pride ourselves on delivering high-quality CNC parts that exceed expectations.

Discover the advanced capabilities of our Industrial CNC Machining Parts. Whether you need precision machining parts or custom machining parts, we have you covered. Our specialized CNC parts are designed to withstand the demands of any industry.

Invest in our Five-Axis CNC Machined Parts and Four-Axis CNC Machined Parts for exceptional performance. These machined milling parts and packing machine ratchet parts are engineered to deliver optimal results.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we are committed to providing you with the best. Our durable and reliable CNC Machining Parts are the epitome of excellence. Trust in our efficient Four-Axis CNC Parts and reliable Five-Axis CNC Parts to elevate your machining experience.

Motor Shaft Copper Sleeve

Experience the precision and quality of our Motor Shaft Copper Sleeve, crafted with utmost care and expertise by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. Our team of skilled professionals utilizes the finest H59 brass material, ensuring exceptional durability and performance.

Through a meticulous process, the copper sleeve undergoes precision CNC turning, followed by 5-axis CNC milling, and finally, a surface treatment through electroplating. This comprehensive approach guarantees a flawless finish and optimal functionality.

Whether you require CNC Machining Parts, Five-Axis Machining Parts, or Milling Parts, our Motor Shaft Copper Sleeve is a versatile solution that meets your specific needs. Its high-quality construction and customizability make it suitable for various applications, including Packing Machines, Ratchet Systems, and Carrier Tape Needle Wheels.

Choose our Motor Shaft Copper Sleeve for its advanced machining capabilities, reliable performance, and efficient functionality. Trust in our expertise to deliver durable and precise CNC Machined Components that exceed your expectations.

Robot Accessory Bracket: Made of AL6061 aluminum alloy, this bracket is crafted using advanced five-axis milling technology and features a natural oxidized surface treatment. Perfect for various industrial applications.

Calm and Soothing Fine-Tuning Dial for Terminal Machines and Mechanical Equipment

Introducing the fine-tuning dial by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This high-quality dial is designed to provide precise scale adjustment for terminal machines and mechanical equipment, ensuring optimal performance and accuracy.

Our fine-tuning dial is crafted from durable carbon steel, known for its exceptional hardness and longevity. Through the use of CNC lathe and precision 5-axis CNC technology, we have achieved unparalleled precision in its construction. To further enhance its durability and aesthetics, the dial is electroplated on the surface.

With our fine-tuning dial, you can effortlessly adjust the scale of your terminal machines and mechanical equipment, allowing for seamless operation and improved efficiency. Its reliable performance ensures that your equipment operates at its best, minimizing downtime and maximizing productivity.

Choose the calm and soothing fine-tuning dial from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for your scale adjustment needs. Experience the precision, durability, and efficiency that our high-quality CNC machining parts offer.

Calm and Soothing Speech Microphone

Experience the ultimate in audio clarity with our Speech Microphone. Crafted from high-quality AL6063 aluminum alloy material, this microphone is designed to deliver exceptional performance in any setting. Whether you’re in a KTV, school, karaoke hall, stage, or any other public place, our Speech Microphone ensures that your voice is heard with crystal-clear precision.

Using state-of-the-art CNC lathe and 5-axis CNC technology, our microphone is meticulously crafted to perfection. The surface is then treated with a luxurious gold oxidation, adding a touch of elegance to its sleek design.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we specialize in producing top-of-the-line CNC Machining Parts. Our expertise lies in creating custom Five-Axis Machining Parts that are durable, reliable, and efficient. With our advanced machining capabilities, we can deliver precision CNC parts that meet the highest industry standards.

Key Features:

- AL6063 aluminum alloy material for superior durability

- CNC lathe and 5-axis CNC technology for precise manufacturing

- Gold oxidation surface treatment for an elegant finish

- Perfect for KTV, schools, karaoke halls, stages, speeches, and more

Choose our Speech Microphone and elevate your audio experience to new heights. Trust in our expertise and let us provide you with the highest-quality CNC Machining Parts available on the market.

Titanium Alloy Interface

Experience the exceptional quality and precision of our Titanium Alloy Interface. Crafted from Tc4 titanium alloy material using state-of-the-art CNC processing techniques, this interface is perfect for a wide range of applications including equipment interfaces, mechanical interfaces, and aviation plug interfaces.

About Us

Welcome to HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a leading manufacturer with over 20 years of experience in the industry. Located in HangZhou City, ZheJiang Province, China, we specialize in the production and trade of high-quality precision parts. Our advanced production and processing technology, combined with our commitment to innovation, ensures that we deliver exceptional products to our valued customers.

CNC Training Parts

Discover our range of Five-Axis CNC Machining Parts, designed to meet the highest standards of quality and precision. Whether you need CNC Machining Parts, Four-Axis Machining Parts, or Milling Parts, we have you covered. Our expertise extends to various industries, including packing machines, ratchet systems, and carrier tape needle wheels. With our custom machining capabilities, we can provide you with the perfect solution for your specific needs.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we pride ourselves on our attention to detail and our dedication to customer satisfaction. Our team of experienced designers and R&D personnel work tirelessly to ensure that our CNC Machined Components meet the most demanding requirements. With our specialized CNC parts and advanced machining techniques, you can trust in the durability, reliability, and efficiency of our products.

Experience the difference of our high-quality CNC Machining Parts today. Contact us for more information or to discuss your specific requirements.

5-Axis CNC Workshop

Discover our high-quality CNC machining parts at HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. We specialize in custom five-axis machining parts, offering precision and durability. Our efficient four-axis CNC parts are perfect for industrial applications. Explore our advanced and reliable CNC components today!

Five-Axis CNC Machining Parts

Five-Axis CNC Machining Parts

Experience precision and quality with our Five-Axis CNC Machining Parts. Crafted by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., our parts are designed to meet your specific needs.

Our factory, spHangZhou over 2,000 square meters, is equipped with state-of-the-art production equipment including CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, and die-casting equipment. This ensures the highest level of precision and accuracy in every part we produce.

With our 2.5-dimensional detection equipment, we guarantee the quality and reliability of our machining parts. Each part undergoes thorough inspection to ensure it meets the highest industry standards.

Whether you require CNC Machining Parts, Four-Axis Machining Parts, Milling Parts, or any other specialized CNC parts, we have you covered. Our custom machining parts are tailored to your unique requirements, providing efficient and durable solutions.

Trust in our expertise and experience. Our Five-Axis CNC Machining Parts are widely used in various industries, including industrial CNC machining, packing machines, and more. We pride ourselves on delivering high-quality CNC parts that you can rely on.

Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for your precision machining needs. Contact us today to discuss your requirements and let us provide you with the perfect solution.

Three-dimensional Imager

Enhance your production process with our state-of-the-art three-dimensional imager. Designed and manufactured by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a trusted leader in CNC machining parts, this imager is the perfect addition to your auxiliary production equipment.

With our complete testing equipment, including sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector, and other conventional testing equipment, you can ensure the highest quality and precision in your manufacturing process.

Experience peace of mind knowing that our imager is crafted with the utmost attention to detail and precision. It is perfect for electroplating, anodizing, hard anodizing, and surface treatment, providing you with exceptional results every time.

If you are interested in our products, please contact us for the best price support and quality service. Trust in HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. to meet all your CNC machining needs.

Welcome to HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., where we specialize in providing high-quality Five-Axis CNC Machining Parts. With our extensive experience and cooperation with top material suppliers, we guarantee the utmost quality in our products.

When it comes to materials, we offer a wide range of options to suit your specific requirements. Choose from aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, acrylic, and more. Rest assured that all our materials come with supporting documents for your peace of mind.

For surface treatment, we have established long-standing partnerships with reliable suppliers who are well-versed in meeting our quality standards. Whether you need heat treatment, spray painting, powder coating, blackening, plating, polishing, or any other treatment, we have you covered.

One of our specialties is aluminum alloy surface oxidation, which enhances the durability and appearance of the parts. This process ensures that your CNC Machining Parts not only perform flawlessly but also look visually appealing.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we pride ourselves on delivering precision and CHINAMFG in every product we create. Our Five-Axis CNC Machining Parts are designed to meet the highest industry standards, making them ideal for various applications.

Choose us for your machining needs, and we guarantee a good and long-term cooperation. Feel free to send us pictures and letters to discuss your requirements. Thank you for considering HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. as your trusted partner in CNC machining.

Dust-free electroless nickel plating on carbon steel surface. Enhance durability and reliability. Perfect for industrial CNC machining parts. Get high-quality CNC machined components from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.

FAQ

Product Description: Five-Axis CNC Machining Parts

Looking for high-quality CNC machining parts? Look no further! At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we specialize in providing custom five-axis machining parts that are durable, reliable, and efficient.

Our precision CNC parts are meticulously crafted by our team of 17 experienced engineers using advanced machining techniques. With over 50 skilled employees and a spacious 3,000m2 workshop area, we have the capacity to handle projects of any size.

Whether you need milling parts, packing machine parts, ratchet parts, or carrier tape needle wheel parts, our CNC machining expertise ensures precise and accurate results. We pride ourselves on delivering products that meet your exact specifications.

When it comes to quality, we never compromise. We understand the importance of delivering goods that exceed your expectations. That’s why we offer samples before mass production, allowing you to assess the quality firsthand.

Rest assured, your drawings and designs are safe with us. We prioritize your privacy and will not release any information to third parties without your permission.

Worried about staying updated on the progress of your products? We’ve got you covered. We provide detailed production schedules and send weekly reports with digital pictures and videos, allowing you to track the machining progress from the comfort of your own office.

Ready to get started? Simply send us an inquiry email with your product drawings in PDF format. If you have STEP or IGS files, even better! We’ll promptly respond and provide you with a quote tailored to your specific needs.

For payment, we accept a 50% deposit, and once the goods are prepared, we’ll provide photos or videos for your inspection before you pay the balance. We offer flexible payment options, including Paypal for small quantities and T/T for larger amounts.

When it comes to delivery, we rely on trusted courier companies to ensure your products reach you safely and on time.

Don’t have drawings? No problem! Simply send us a sample, and our skilled team will create CAD or 3D files based on your specifications, providing you with better solutions.

Experience the precision and quality of our five-axis CNC machining parts. Contact us today to discuss your requirements and let us exceed your expectations!

Packing&Shipping

Calm and Soothing Packaging Details

Our Five-Axis CNC Machining Parts are carefully packaged to ensure their safe delivery and protection. We offer 2 types of packaging options:

- Commercial packaging: Each piece is individually packed in a plastic bag, then placed in a color box. These boxes are then securely packed in a carton and placed on a pallet for added stability.

- Industrial packaging: We provide 2 options for industrial packaging. The first option includes packing the parts in a plastic tube, which is then placed in a carton and secured on a pallet. The second option involves packing the parts in a plastic bag, followed by wrapping them in kraft paper. These wrapped parts are then placed in a carton and secured on a pallet.

We understand that every customer has unique requirements, so we are flexible and can accommodate any specific packaging needs you may have.

About HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.

HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. is a reputable company specializing in the production of high-quality CNC Machining Parts. With our advanced machining capabilities, we are able to provide precision CNC parts that meet the highest industry standards.

Product Description: Five-Axis CNC Machining Parts

Our Five-Axis CNC Machining Parts are meticulously crafted to deliver exceptional performance and durability. These precision machined parts are perfect for various applications, including milling machines, packing machines, and more.

Key Features:

- Advanced Five-Axis Machining: Our parts are manufactured using state-of-the-art five-axis CNC machining technology, ensuring precise and efficient production.

- Customizable Options: We offer custom machining services, allowing you to tailor the parts to your specific requirements.

- Industrial-Grade Quality: Made from high-quality materials, our CNC Machining Parts are built to withstand rigorous industrial environments.

- Reliable Performance: Our parts are designed to deliver consistent and reliable performance, ensuring smooth operation and minimal downtime.

Whether you need specialized CNC parts or general machining components, our Five-Axis CNC Machining Parts are the perfect choice. Trust in our expertise and experience to provide you with durable and efficient solutions for your machining needs.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Professional Service |

|---|---|

| Warranty: | 30 Days |

| Condition: | New |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the impact of ratchet wheels on the overall safety of mechanical systems?

Ratchet wheels play a crucial role in enhancing the overall safety of mechanical systems in various applications. Their impact on safety can be summarized as follows:

- 1. Preventing Unintended Backdriving: One of the primary safety benefits of ratchet wheels is their ability to prevent unintended backdriving or reverse motion. When a pawl or catch mechanism engages with the teeth of the ratchet wheel, it locks the wheel in place, ensuring that the system does not move in the undesired direction. This feature is especially important in applications where maintaining a specific position or preventing sudden movement is critical for safety.

- 2. Controlled Motion: Ratchet wheels provide controlled and incremental motion, allowing users to make precise adjustments or movements. This controlled motion is essential in applications where precise positioning or controlled advancement is necessary for safety reasons, such as in medical devices, manufacturing equipment, or safety mechanisms.

- 3. Safety Interlocks: Ratchet wheels are often used in safety interlock systems where certain conditions must be met for a system to operate safely. For example, in industrial machinery, a ratchet wheel and pawl mechanism can be part of an interlock system that ensures equipment remains stationary until specific safety conditions are met, reducing the risk of accidents.

- 4. Load Handling and Securement: In load handling and securement applications, such as winches and tie-down straps, ratchet wheels help maintain tension and prevent slack. This contributes to the safe transportation of loads, reducing the risk of load shifts or accidents during transit.

- 5. Emergency Stop Systems: Ratchet wheels are employed in emergency stop systems to ensure that once the system is activated, it remains in a safe state until intentionally reset. This safety feature is vital in machinery and equipment where rapid shutdown is necessary to prevent hazards.

- 6. Reliability and Predictability: Ratchet wheels offer reliability and predictability in their operation. Users can apply force or torque in the desired direction with confidence, knowing that the ratchet mechanism will engage and prevent unexpected movement. This predictability enhances the overall safety of the system.

- 7. Versatility in Safety Applications: Ratchet wheels find application in a wide range of safety-critical systems, including vehicle handbrakes, safety gates, medical devices, and more. Their ability to provide controlled and secure motion makes them versatile components in various safety applications.

In summary, ratchet wheels contribute significantly to the safety of mechanical systems by preventing unintended movement, providing controlled motion, enabling safety interlocks, and enhancing reliability. Their presence in safety-critical applications helps reduce the risk of accidents and ensures that systems operate safely and predictably.

How do ratchet wheels contribute to the precision and repeatability of certain applications?

Ratchet wheels play a pivotal role in enhancing precision and repeatability in various applications by providing controlled and incremental motion. Their contributions to precision and repeatability can be explained as follows:

- 1. Controlled Movement: Ratchet wheels are designed to engage with pawls or catches in a way that allows them to move in only one direction while preventing backward movement. This controlled movement ensures that adjustments, increments, or positioning occur with a high degree of accuracy.

- 2. Incremental Adjustments: In applications where precision is crucial, such as in manufacturing, assembly, or calibration equipment, ratchet wheels enable users to make incremental adjustments or movements. This precision allows for fine-tuning and achieving the exact desired outcome.

- 3. Consistency and Repeatability: Ratchet mechanisms, including ratchet wheels, provide a consistent and repeatable motion. Users can reliably achieve the same result repeatedly, ensuring product consistency in manufacturing or consistent positioning in various tasks.

- 4. Safety and Position Locking: Ratchet wheels are commonly used in safety-critical applications where specific positions must be securely locked. This locking feature not only enhances safety but also ensures that a particular setting or position remains precise and repeatable.

- 5. Indexing and Positioning: In applications like indexing tables or machinery requiring precise indexing or positioning, ratchet wheels enable accurate and repeatable alignment of components or workpieces. This is essential for processes such as drilling, milling, or assembly.

- 6. Calibration and Measurement: Ratchet mechanisms are utilized in calibration equipment to allow for precise adjustments of measuring instruments. This contributes to the accuracy and repeatability of measurements, which is critical in scientific, laboratory, and metrology applications.

- 7. Safety Interlocks: Ratchet wheels are often part of safety interlock systems that require specific conditions to be met before certain operations can proceed. This ensures that critical safety protocols are consistently followed.

- 8. Reliability in Emergency Systems: Ratchet mechanisms are incorporated into emergency systems where reliability and repeatability are paramount. For example, emergency stop systems rely on the repeatability of ratchet wheels to ensure consistent and immediate shutdown of machinery.

- 9. Reducing Human Error: In applications where human operators are involved, ratchet wheels help reduce the likelihood of errors. The controlled and incremental motion they provide minimizes the risk of overshooting or undershooting desired settings.

In summary, ratchet wheels contribute to precision and repeatability by enabling controlled and incremental motion, ensuring consistent and repeatable results, and enhancing safety in various applications across industries.

In what mechanical devices or tools are ratchet wheels commonly used, and how do they operate?

Ratchet wheels are commonly used in various mechanical devices and tools, where they play a crucial role in enabling unidirectional motion and preventing backward movement. Here are some examples of mechanical devices and tools that incorporate ratchet wheels and an explanation of how they operate:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, are widely used in automotive repair and mechanical work. They feature a ratchet wheel mechanism in the wrench head. When the user turns the handle in one direction, the ratchet wheel engages with the socket, allowing continuous rotation for fastening or loosening bolts or nuts. When the direction is reversed, the ratchet wheel disengages, preventing backward motion and allowing the user to reposition the wrench without removing it from the fastener.

- 2. Ratchet Straps and Tie-Downs: Ratchet straps and tie-downs are used for securing cargo on trucks, trailers, and in various transportation applications. They consist of a ratchet mechanism and a strap with hooks. By cranking the ratchet handle, the ratchet wheel tightens the strap, providing secure tension. The ratchet prevents the strap from unwinding or loosening during transit, ensuring that the load remains securely fastened.

- 3. Handbrakes in Vehicles: In automobiles, ratchet wheels are a fundamental component of handbrakes (parking brakes). When the handbrake lever is pulled, it engages a ratchet mechanism that locks the rear wheels in place, preventing the vehicle from rolling when parked on an incline. Releasing the handbrake disengages the ratchet, allowing normal wheel rotation.

- 4. Winches and Hoists: Winches and hoists used in industries such as construction, manufacturing, and material handling rely on ratchet wheel mechanisms. The ratchet wheel controls the winding and unwinding of cables or ropes. When the user operates the winch or hoist in one direction, the ratchet allows the cable to be pulled in and wound onto a drum. In the opposite direction, the ratchet prevents the cable from unwinding, ensuring controlled load handling.

- 5. Bike Gears: Bicycle gears often use ratchet mechanisms to control gear shifting. When a cyclist pedals forward, the ratchet wheel engages with the gear sprocket, allowing the chain to move smoothly and propel the bike. If the cyclist pedals backward or stops pedaling, the ratchet prevents the chain from moving in reverse, ensuring efficient pedaling and preventing the bike from rolling backward.

- 6. Fishing Reels: Many fishing reels, including spinning reels and baitcasting reels, incorporate ratchet mechanisms. The ratchet wheel in the reel allows the fishing line to be pulled in when the angler reels in a fish. The ratchet prevents the line from spooling out when there is no tension on it, ensuring that the line remains taut during fishing.

In each of these applications, the ratchet wheel functions by engaging with a pawl or catch mechanism. When force is applied in the desired direction, the pawl allows the ratchet wheel to rotate freely, enabling the intended motion. When force is applied in the opposite direction, the pawl engages with the teeth on the ratchet wheel, locking it in place and preventing backward movement. This simple yet effective mechanism provides controlled and safe operation in various mechanical devices and tools.

editor by CX 2024-01-05

China Good quality Yn27c Rock Drill Accessory Ratchet Wheel Assy

Product Description

Product Description

The Internal Combustion Rock Drill Hand Held type YN27C can be used as a tool for both breaking and percussive drilling with higher cost performance,which is widely praised by customers.There is a conversion device in the machine,the machine will operate with percussive drilling function if you turn up the lock pin and operate with breaking function if you turn down the lock pin,which is easy to use.

Technical Specification

| Weight of main machine | 27kg |

| Overall dimensions(L*W*H) | 746 *315*229mm |

| Type of engine | single cylinder,air cooled 2 strokes |

| Cylinder diameter*stroke of piston | Φ58*70mm |

| Rotating speed of engine | ≥2450r/min |

| Displacement of engine piston | 185cm³ |

| Type of carburetor | hand needle valve,no floating type |

| Ignition system | controllable silicon, contactless system |

| Drilling speed (mean value of 5 holes) | ≥250mm/min |

| Drilling hole diameter | Φ28-42mm |

| Max drilling depth | 6m |

| Fuel consumption | ≤0.121L/m |

| Tank capacity | ≥1.14L |

| Mixture ratio of gasline and lubricating oil | 12:1 |

| Drill rod and breaker shank | Hexagonal 22*108mm |

| Rotating speed of drill rod | ≥200r/min |

| Clearance of spark plug | 0.5-0.7mm |

Product Detail

Product Application

Certifications

Aoubt Us

HangZhou Sailuoxin Pneumatic Tool Co., Ltd. established in 2018,is a professional manufacturer and exporter that is concerned with the design,development and production of rock drill.We are located in Xihu (West Lake) Dis.,HangZhou,ZHangZhoug province,which is near HangZhou port,one of the biggest ports in the world with convenient transportation access.All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

We have over 20 employees,an annual sales figure that exceeds USD 10,000,000 and are currently exporting 80% of our production worldwide.Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

As a result of our high quality products and outstanding customer service,we have gained a global sales network CHINAMFG Africa,South America

If you are interested in any of our products or would like to discuss a custom order,please feel free to contact us.We are looking CHINAMFG to forming successful business relationships with new clients around the world in the near future.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Motor: | AC Motor |

| Transport Package: | in Cartons |

| Specification: | 240g |

| Trademark: | SLX |

| Origin: | China |

| Customization: |

Available

|

|

|---|

How does the choice of materials impact the durability and performance of ratchet wheels?

The choice of materials significantly impacts the durability and performance of ratchet wheels in mechanical systems. Different materials offer varying levels of strength, wear resistance, and corrosion resistance, influencing how well the ratchet wheel performs over time. Here’s how material selection affects ratchet wheel characteristics:

- 1. Strength and Load Capacity: The material of a ratchet wheel determines its strength and load-bearing capacity. High-strength materials like hardened steel or alloy steel are often chosen for heavy-duty applications, as they can withstand substantial loads without deformation or failure.

- 2. Wear Resistance: Ratchet wheels are subject to wear and friction as they engage with pawls or catches. Materials with excellent wear resistance, such as hardened steel or materials with special coatings, can prolong the lifespan of the ratchet wheel by reducing wear and preventing premature tooth damage.

- 3. Corrosion Resistance: In environments where exposure to moisture, chemicals, or corrosive substances is a concern, selecting corrosion-resistant materials is crucial. Stainless steel and certain alloys are known for their resistance to rust and corrosion, making them suitable for such conditions.

- 4. Weight Considerations: The material’s density impacts the weight of the ratchet wheel. Lighter materials, such as aluminum or certain plastics, can be chosen when weight reduction is a priority, especially in applications where portability or reduced inertia is essential.

- 5. Friction and Efficiency: The material’s surface properties can affect friction and overall efficiency. Some materials may require lubrication to reduce friction, while others have inherent properties that promote smooth engagement and reduce energy losses.

- 6. Cost and Availability: Material choice also affects the cost and availability of ratchet wheels. Common materials like steel are readily available and cost-effective, while specialized materials may be more expensive and less accessible.

- 7. Temperature Resistance: For applications in extreme temperature environments, materials must be chosen that can withstand temperature variations without deformation or loss of mechanical properties.

- 8. Compatibility with Pawls: The material of the ratchet wheel should be compatible with the material of the pawl or catch mechanism to ensure proper engagement and prevent premature wear of either component.

Ultimately, the choice of material should align with the specific requirements of the application. Engineers and designers carefully consider factors such as load capacity, wear resistance, environmental conditions, and cost to select the most suitable material for ratchet wheels, ensuring optimal durability and performance in the intended use.

Are there innovations or advancements in ratchet wheel technology that have emerged recently?

Yes, there have been notable innovations and advancements in ratchet wheel technology in recent years. These developments aim to enhance the performance, efficiency, and versatility of ratchet wheels in various applications. Some of the key advancements include:

- 1. Materials and Coatings: Advances in materials science have led to the development of ratchet wheels made from high-strength and lightweight materials. These materials offer improved durability and reduced wear, extending the service life of ratchet wheels. Additionally, specialized coatings are applied to enhance corrosion resistance and reduce friction.

- 2. Precision Manufacturing: Modern manufacturing techniques, including CNC machining and 3D printing, allow for the production of highly precise ratchet wheel components. This precision ensures smoother engagement and more accurate positioning, making ratchet wheels suitable for applications requiring tight tolerances.

- 3. Miniaturization: In industries like electronics and medical devices, there is a demand for smaller and more compact ratchet mechanisms. Recent advancements have led to miniaturized ratchet wheels that can operate in confined spaces while maintaining their precision and reliability.

- 4. Smart Ratchet Systems: Some innovative ratchet systems incorporate smart technology, such as sensors and feedback mechanisms. These systems can monitor the position and condition of the ratchet wheel in real-time, providing valuable data for diagnostics and maintenance.

- 5. Enhanced Safety Features: Advancements in safety-critical applications have resulted in ratchet wheels with enhanced safety features. These may include fail-safe designs, improved locking mechanisms, and more robust materials to withstand extreme conditions.

- 6. Integration with Automation: Ratchet wheels are increasingly being integrated into automated systems, where they play a crucial role in controlled motion and positioning. These integrated solutions improve efficiency and reduce the need for manual adjustments.

- 7. Customization: Manufacturers now offer greater customization options for ratchet wheels to meet specific application requirements. This includes variations in tooth profiles, sizes, and configurations to accommodate diverse needs.

- 8. Sustainable Materials: As sustainability becomes a more significant concern, there is a growing trend toward using eco-friendly materials in ratchet wheel production. This includes the use of recycled and recyclable materials in their construction.

These innovations in ratchet wheel technology contribute to their adaptability in various industries and applications. Whether it’s improving precision, enhancing safety, or reducing environmental impact, recent advancements have expanded the capabilities of ratchet wheels in mechanical systems.

Can you explain the primary purpose and applications of ratchet wheels in various industries?

Ratchet wheels serve a primary purpose in various industries by enabling unidirectional motion, preventing backward movement, and offering precise control. Their applications are diverse and include the following:

- 1. Automotive Industry: Ratchet wheels are integral to automotive applications, such as handbrakes and vehicle jacks. Handbrakes use ratchet mechanisms to securely hold a vehicle in place, preventing it from rolling when parked on an incline. Vehicle jacks employ ratchet mechanisms for controlled lifting and lowering of vehicles during maintenance or tire changes.

- 2. Construction and Engineering: Construction and engineering equipment often feature ratchet mechanisms. Ratchet straps and tie-downs are used for securing loads on trucks and trailers. Additionally, ratchet wrenches and torque wrenches provide precise control in construction and assembly tasks, allowing for incremental tightening or loosening of bolts and fasteners.

- 3. Manufacturing and Assembly: Ratchet mechanisms are employed in manufacturing and assembly processes where controlled movement is essential. This includes machinery used in factories for precision tasks like fastening, clamping, or incrementally advancing components on an assembly line.

- 4. Medical Devices: The medical industry utilizes ratchet wheels in various instruments and devices. For instance, surgical instruments may feature ratchet mechanisms to control the movement of specific components, allowing surgeons to perform delicate procedures with precision.

- 5. Material Handling: In material handling equipment such as winches, hoists, and cranes, ratchet wheels ensure the controlled lifting and lowering of heavy loads. They contribute to safety and prevent unintended load movement, making them crucial in industries like construction, manufacturing, and logistics.

- 6. Consumer Products: Ratchet mechanisms are found in many consumer products. A common example is a retractable tape measure, where a ratchet wheel allows the tape to be extended and then locked in place at the desired length. Similarly, many hand tools like screwdrivers and pliers feature ratchet mechanisms for efficient and continuous rotation in one direction.

- 7. Aerospace and Aviation: Ratchet wheels are used in aerospace and aviation applications for tasks like securing cargo in aircraft, controlling movements in cockpit instruments, and ensuring the proper operation of various components within the aircraft.

- 8. Marine and Boating: Marine equipment often employs ratchet mechanisms in winches and pulleys for controlling sails, anchors, and other rigging. They enable sailors to adjust sail tension and anchor position with precision.

- 9. Sports and Recreation: Ratchet mechanisms are used in sports and recreational equipment, such as bike gears and fishing reels. They provide controlled motion and prevent backward movement, enhancing the user experience and safety.

Ratchet wheels are versatile components that find applications in an array of industries, improving safety, control, and efficiency across various mechanical systems.

editor by CX 2024-01-05