Product Description

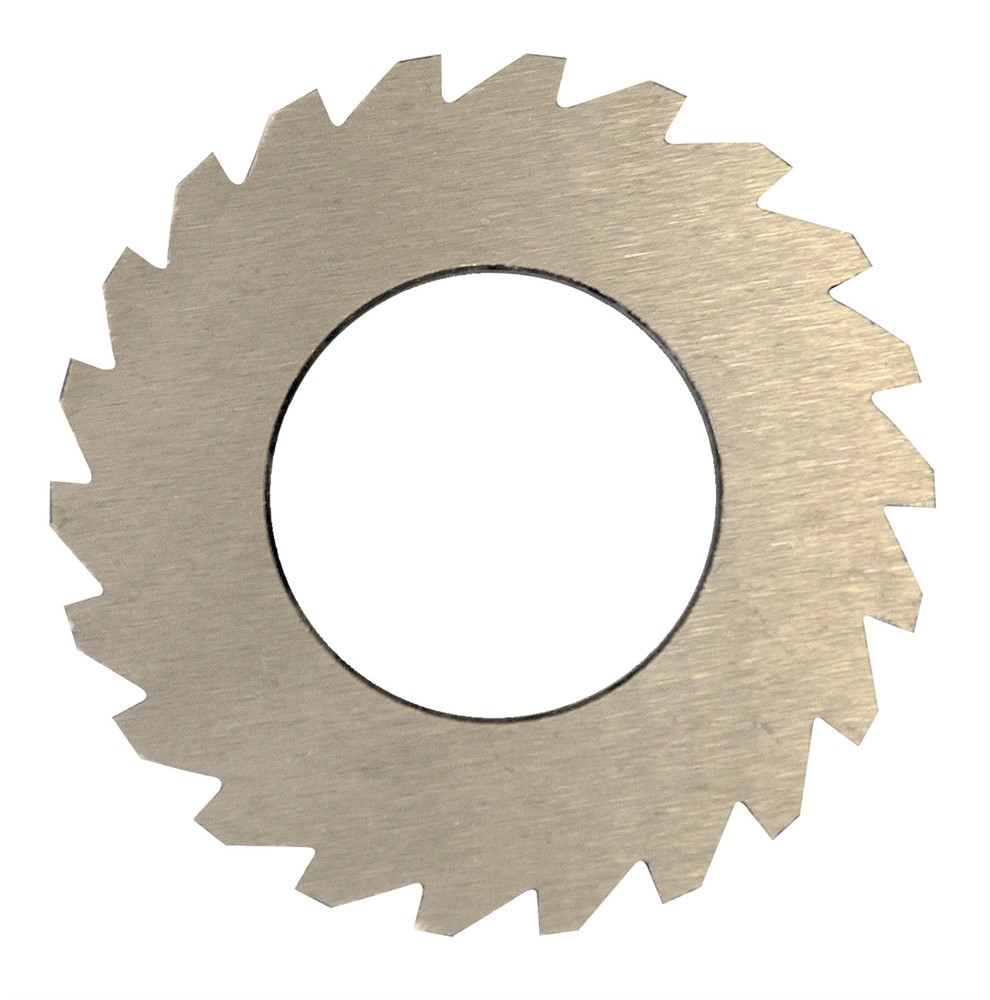

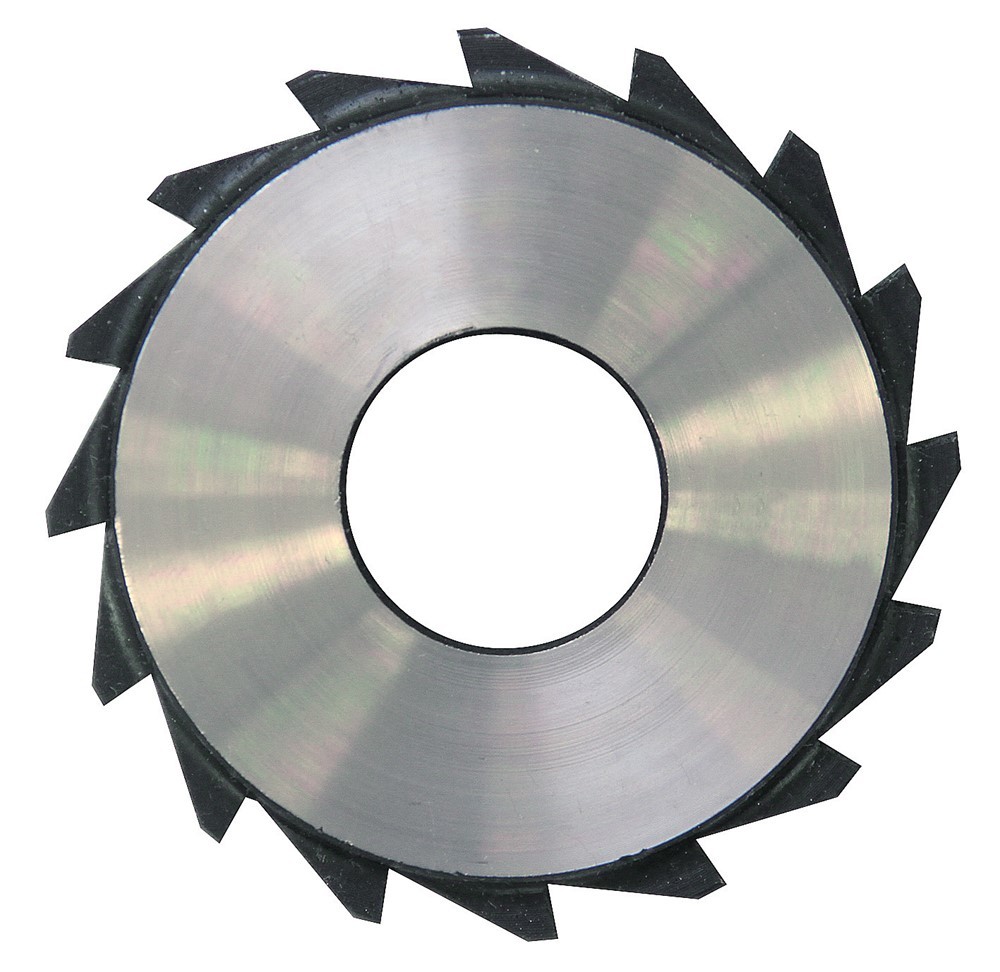

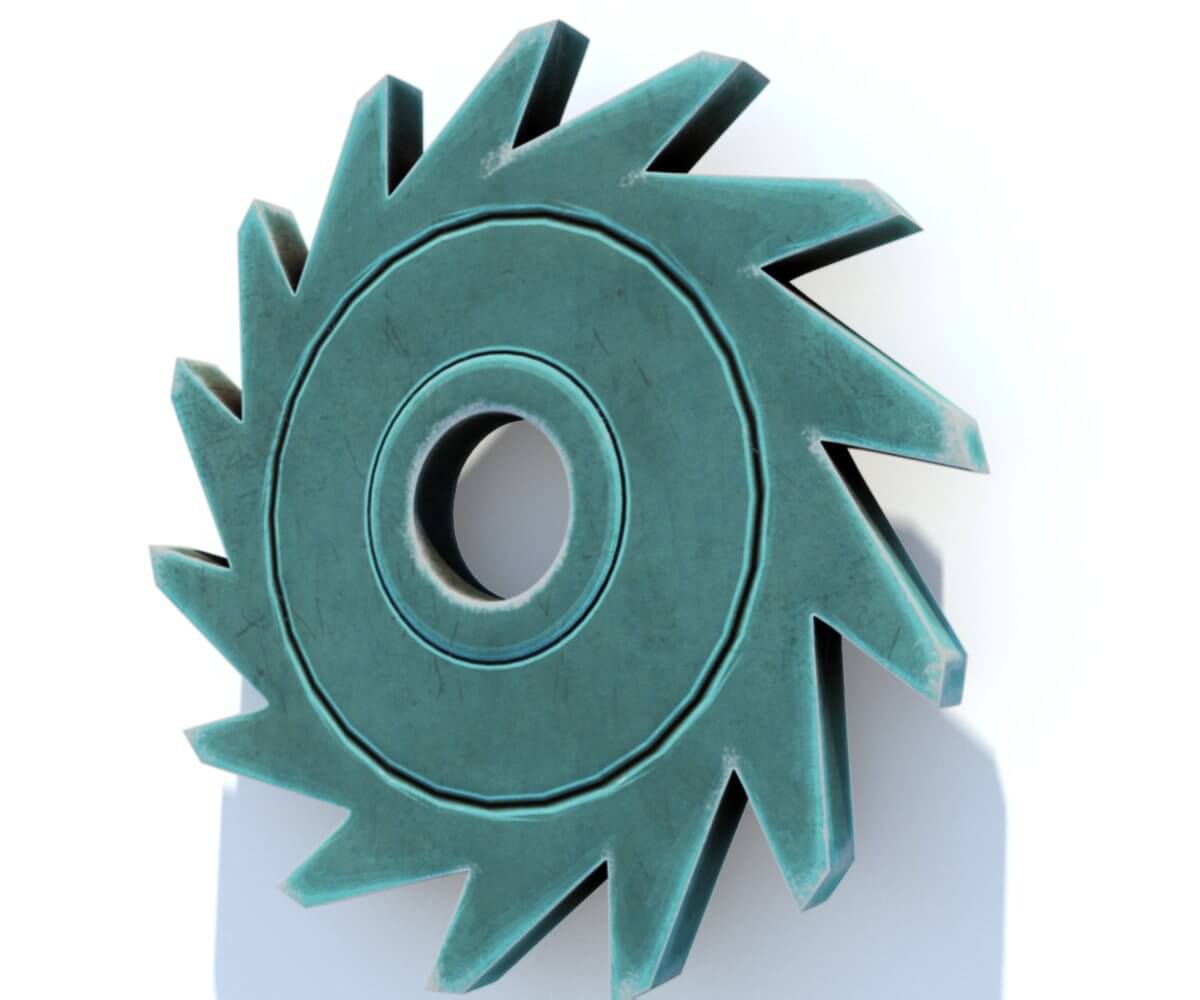

Introducing the Carrier Pin Wheel for Ratchet Pin Wheel by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This unique pin wheel is made of alloy steel and is perfect for customized processing and packaging machines. It features five-axis machining and CNC machining components for precision and durability. Upgrade your machine with this high-quality pin wheel today!

Product Description

| Production type |

Custom production and processing |

Material |

Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods |

CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting |

Processing Equipment |

CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy |

±0.05mm |

Whether proofing |

yes |

| Is it customized |

yes |

Proofing time |

7-15 days |

| OEM/ODM |

OEM ODM CNC machining service |

surface treatment |

Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin |

HangZhou, China |

Quotations |

FOB |

| Business Type: |

Manufacturer/Factory & Trading Company |

Main Products: |

CNC parts; Machining parts |

| Management System Certification: |

ISO 9001:2015 |

Average Lead Time: |

Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Product Parameters

Discover our high-quality Cam Machining Parts for Semiconductor Vibration Plate. Made from alloy steel, these precision components are perfect for the semiconductor industry. With our advanced machining technology, we provide reliable and custom CNC parts for your needs.

Calm and Soothing Product Description: Cam Machining Parts for Semiconductor Vibration Plate

Introducing the Cam Machining Parts for Semiconductor Vibration Plate, brought to you by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. Our high-quality machining parts are designed to enhance the performance of your semiconductor vibration plate, providing you with reliable and efficient solutions for your semiconductor manufacturing needs.

Our precision cam components are meticulously crafted using advanced machining technology. The alloy steel construction ensures durability and longevity, making these parts a reliable choice for your cam wheel assembly. With our custom CNC parts, you can expect precise and accurate machining, guaranteeing optimal performance.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we understand the importance of precision in the semiconductor industry. That’s why our cam machining accessories, such as the pulling wheel, carrier pin wheel, and ratchet, are manufactured with utmost care and attention to detail. These components play a crucial role in the smooth operation of your vibration plate, ensuring consistent and reliable performance.

With our expertise in precision machining, we offer machining services that meet the highest standards. Our CNC parts are processed using CNC turning and precision 5-axis CNC, resulting in a rough blank that is then surface electroplated for a flawless finish. This meticulous process guarantees the quality and reliability of our machining parts.

Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. as your trusted machining supplier for all your semiconductor vibration plate needs. Experience the benefits of our high-quality cam machining solutions and take your semiconductor manufacturing to the next level.

Calm and Soothing Product Description: Motor Shaft Copper Sleeve

Introducing the Motor Shaft Copper Sleeve, a high-quality precision component designed to enhance the performance of your machinery. Crafted with utmost care and expertise by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a reliable machining supplier in the semiconductor industry.

Our Motor Shaft Copper Sleeve is made from H59 brass, a material known for its exceptional durability and reliability. Through precision CNC turning and 5-axis CNC milling, we ensure the utmost accuracy and precision in every detail of this component.

To further enhance its longevity and aesthetics, the Motor Shaft Copper Sleeve undergoes a meticulous electroplating process for surface treatment. This not only adds a touch of elegance but also provides an extra layer of protection against wear and tear.

With its impeccable craftsmanship and advanced machining technology, our Motor Shaft Copper Sleeve is the perfect choice for semiconductor vibration plates, cam machining parts, pulling wheels, carrier pin wheels, ratchets, and more. Its compatibility with various machinery makes it a versatile solution for your machining needs.

Experience the difference of our Motor Shaft Copper Sleeve and elevate the performance of your machinery. Trust in the expertise of HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. to deliver high-quality machining parts that meet your exact specifications.

Robot accessory bracket: Made of AL6061 aluminum alloy through 5-axis milling and natural surface treatment.

Calm and Soothing Fine-Tuning Dial for Terminal Machines and Mechanical Equipment

Introducing our high-quality fine-tuning dial, designed to bring precision and durability to your terminal machines and mechanical equipment. Made from carbon steel with exceptional hardness, this dial has undergone meticulous processing using CNC lathe and precision 5-axis CNC technology. To ensure longevity, the surface has been electroplated for added protection.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we specialize in providing top-notch machining parts for various industries. Our Cam Machining Parts for Semiconductor Vibration Plate are meticulously crafted to meet the demanding requirements of the semiconductor industry.

Key Features:

- Alloy steel construction for enhanced strength and reliability

- Precision machining using advanced 5-axis CNC technology

- Customizable CNC parts to suit your specific needs

- Perfect for semiconductor manufacturing and vibration plate components

-

-

With our fine-tuning dial, you can easily adjust the scale of your terminal machines and mechanical equipment, ensuring optimal performance and efficiency. Whether you need to fine-tune a pulling wheel, carrier pin wheel, or ratchet, our dial is the perfect solution.

Trust in our reliable machining services and benefit from our expertise in the semiconductor industry. Our Cam Machining Parts are designed to deliver exceptional performance and longevity, making them the ideal choice for your machining needs.

Calm and Soothing Speech Microphone

Experience the tranquility of our Speech Microphone, crafted with precision using AL6063 aluminum alloy material. Through the meticulous process of CNC lathe and 5-axis CNC, this microphone is transformed into a masterpiece. Its surface is delicately oxidized with a luxurious gold finish, adding a touch of elegance to any setting.

Designed for various public places, our Speech Microphone is perfect for KTV, schools, karaoke halls, stages, and speeches. Its exceptional quality ensures crystal-clear sound transmission, allowing your voice to resonate effortlessly. Whether you’re addressing a crowd or performing on stage, our microphone guarantees a calm and soothing experience for both you and your audience.

Trust in the expertise of HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a reliable machining supplier in the semiconductor industry. Our Cam Machining Parts for Semiconductor Vibration Plate are meticulously crafted using advanced machining technology. With precision cam components and high-quality machining parts, our solutions cater to the specific needs of the semiconductor manufacturing process.

Key Features:

- Alloy steel construction for durability and longevity

- Five-axis machining for precise performance

- Custom CNC parts tailored to your requirements

- Reliable and efficient machining services

-

-

Enhance your semiconductor vibration plate with our Cam Machining Parts. From pulling wheels to carrier pin wheels and ratchets, our machining accessories are designed to optimize the performance of your equipment. Experience the seamless integration of our steel ratchet wheel and precision cam components, ensuring smooth operation and increased productivity.

Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for all your machining needs in the semiconductor industry. Our commitment to delivering high-quality machining parts and exceptional customer service sets us apart. Trust in our expertise and let us provide you with reliable solutions that exceed your expectations.

Titanium Alloy Interface

Experience the exceptional quality and precision of our Titanium Alloy Interface. Crafted from Tc4 titanium alloy material using state-of-the-art CNC processing techniques, this interface is perfect for a wide range of applications including equipment interfaces, mechanical interfaces, and aviation plug interfaces.

Company Profile

About Us

Welcome to HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a renowned manufacturer with over 20 years of industry and trade expertise. Located in HangZhou City, ZheJiang Province, China, we pride ourselves on our advanced high-end professional production and processing technology. Our dedicated team of technical management personnel, experienced designers, and R&D experts work tirelessly to deliver innovative solutions. With a perfect company management system in place, we are committed to providing you with the highest quality products.

CNC Training Parts

Introducing our Cam Machining Parts for Semiconductor Vibration Plate, designed to meet the specific needs of the semiconductor industry. Made from alloy steel and manufactured using advanced five-axis CNC machining technology, these precision parts include pulling wheels, carrier pin wheels, ratchets, and more. Our high-quality machining solutions ensure reliable performance and seamless integration into your semiconductor manufacturing process.

5-axis CNC Workshop

Discover high-quality machining parts and custom CNC solutions for the semiconductor industry. Our advanced machining technology and reliable supplier services ensure precision and efficiency. Explore our range of cam machining parts, including semiconductor vibration plates, pulling wheels, carrier pin wheels, ratchets, and more. Trust in our expertise in alloy steel machining and precision cam components. Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for all your machining needs.

Calm and Soothing Product Description: Cam Machining Parts for Semiconductor Vibration Plate

Introducing our high-quality Cam Machining Parts for Semiconductor Vibration Plate, designed and manufactured by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. With a focus on precision and reliability, our machining parts are perfect for the semiconductor industry.

Our factory, spHangZhou over 2,000 square meters, is equipped with state-of-the-art production equipment, including CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, and die-casting equipment. This allows us to master core processing technologies and deliver exceptional results.

Featuring alloy steel construction, our Cam Machining Parts are built to withstand the demands of the semiconductor manufacturing process. The precision machining ensures optimal performance, while the cam wheel assembly guarantees smooth and efficient operation.

With our advanced machining technology, we offer custom CNC parts tailored to your specific requirements. Whether you need pulling wheels, carrier pin wheels, ratchets, brooch pins, or any other cam machining accessories, we have you covered.

Choose our Cam Machining Parts for Semiconductor Vibration Plate and experience the benefits of reliable machining. Trust in our expertise and let us provide you with high-quality machining solutions for your semiconductor industry needs.

Three-dimensional Imager

Enhance your production process with our high-quality auxiliary production equipment. Our range includes electroplating, anodizing, hard anodizing, and surface treatment equipment. These advanced technologies ensure superior results and impeccable surface finishes.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we prioritize precision and quality. That’s why we offer a complete range of testing equipment to ensure the utmost accuracy in our products. Our sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector, and other conventional testing equipment guarantee the highest standards of quality control.

If you are interested in our products, please don’t hesitate to contact us. We are committed to providing the best price support and quality service to meet your needs.

Welcome to HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., where we specialize in providing high-quality machining parts for the semiconductor industry. Our expertise lies in producing precision cam components, including cam machining parts, pulling wheels, carrier pin wheels, ratchets, and more.

Our Advantages

We take pride in our long-standing partnerships with reputable material suppliers, ensuring that the materials we use are of the highest quality. Whether you require aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, or acrylic, we have you covered. Rest assured that all our materials come with supporting documents for your peace of mind.

When it comes to surface treatment, our experienced suppliers are well-versed in meeting the stringent quality requirements. From heat treatment to spray painting, powder coating to plating, we offer a wide range of options to suit your specific needs. Our surface treatment processes include aluminum alloy surface oxidation, ensuring a durable and visually appealing finish.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we understand the importance of precision and reliability in the semiconductor industry. That’s why we utilize advanced machining technology and employ a five-axis machining approach to deliver exceptional results. Our CNC parts are custom-made to meet your exact specifications, guaranteeing a perfect fit and optimal performance.

Choose us as your reliable machining supplier, and experience the benefits of our high-quality machining parts. Whether you need components for vibration plates or cam machining accessories, we have the solutions you’re looking for. Trust in our expertise in the semiconductor manufacturing industry, and let us provide you with top-notch machining services.

Discover the difference that our alloy steel machining can make in your operations. Our precision cam components and steel ratchet wheels are designed to withstand the demands of the semiconductor industry, ensuring long-lasting performance and reliability.

Contact us today to discuss your requirements. We welcome your pictures and letters, and we look CHINAMFG to establishing a good and long-term cooperation with you. Thank you for considering HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. as your trusted partner in precision machining.

HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. offers high-quality dust-free electroless nickel plating on carbon steel surfaces. Perfect for semiconductor vibration plates, our precision machining parts, including cam machining accessories and steel ratchet wheels, are the ideal solution for the semiconductor industry. Trust our reliable machining services and advanced technology for all your machining needs.

FAQ

Product Description: Cam Machining Parts for Semiconductor Vibration Plate

Our Cam Machining Parts for Semiconductor Vibration Plate are precision-engineered components designed to enhance the performance and reliability of semiconductor vibration plates. Made from high-quality alloy steel, these parts are meticulously machined using advanced CNC technology and five-axis machining techniques.

With our expertise in the semiconductor industry, we understand the critical role that vibration plates play in ensuring smooth and efficient operations. Our Cam Machining Parts, including pulling wheels, carrier pin wheels, ratchets, and brooch pins, are specifically designed to meet the demanding requirements of the semiconductor manufacturing process.

By utilizing our custom CNC parts, you can optimize the performance of your vibration plates, resulting in improved productivity and reduced downtime. The precision cam components and steel ratchet wheels ensure smooth and precise movements, allowing for accurate positioning and reliable operation.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we take pride in our commitment to delivering high-quality machining parts. Our experienced engineers and skilled workforce, along with our state-of-the-art workshop, ensure that every component meets the highest standards of quality and precision.

When you choose our Cam Machining Parts, you can expect exceptional craftsmanship, reliable performance, and long-lasting durability. We prioritize customer satisfaction and strive to exceed your expectations with our reliable machining solutions.

Whether you need machining services for semiconductor vibration plate components or any other precision machining requirements, we are your trusted supplier. Rest assured that your product drawings and specifications will be kept confidential, and we will provide regular updates on the production progress, including detailed schedules, digital pictures, and videos.

Experience the difference of working with a reliable machining supplier. Contact HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. today to discuss your specific needs and discover how our Cam Machining Parts can enhance the performance of your semiconductor vibration plates.

Packaging & Shipping

Calm and Soothing Tone: Cam Machining Parts for Semiconductor Vibration Plate

Experience the highest quality machining parts with our Cam Machining Parts for Semiconductor Vibration Plate. Designed and manufactured by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a reliable machining supplier in the semiconductor industry, these precision cam components are perfect for your semiconductor manufacturing needs.

Our Cam Machining Parts are made from alloy steel, ensuring durability and long-lasting performance. With advanced machining technology and five-axis machining capabilities, we guarantee precise and accurate results every time.

Featuring a ratchet wheel, pulling wheel, carrier pin wheel, and brooch pin, our Cam Machining Parts provide exceptional functionality and reliability. They are designed to optimize the performance of your vibration plate, ensuring smooth and efficient operation.

Whether you need custom CNC parts or cam machining solutions, our machining services have got you covered. We offer a wide range of packaging options to suit your requirements, including commercial packaging and industrial packaging.

Trust HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for all your machining needs. Contact us today to learn more about our Cam Machining Parts for Semiconductor Vibration Plate and how they can enhance your semiconductor manufacturing process.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: |

Professional Service |

| Warranty: |

30 Days |

| Certification: |

ISO9001, ISO, CE |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order)

|

Order Sample

|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

Shipping Cost:

Estimated freight per unit.

|

about shipping cost and estimated delivery time.

|

| Payment Method:

|

|

|

|

Initial Payment

Full Payment

|

| Return&refunds:

|

You can apply for a refund up to 30 days after receipt of the products.

|

What maintenance practices are recommended for ratchet wheels to ensure optimal functionality?

Maintaining ratchet wheels is essential to ensure their optimal functionality and longevity in mechanical systems. Here are recommended maintenance practices for ratchet wheels:

- 1. Regular Inspection: Perform routine visual inspections of the ratchet wheel and the surrounding components. Look for signs of wear, damage, or deformation. Pay attention to the teeth, as worn or damaged teeth can affect engagement.

- 2. Cleaning: Keep the ratchet wheel and associated components clean from dirt, debris, and contaminants. Clean with a suitable solvent or degreaser to remove built-up grime and ensure smooth operation.

- 3. Lubrication: Apply a suitable lubricant to the ratchet wheel and pawl or catch mechanism to reduce friction and prevent premature wear. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

- 4. Pawl or Catch Inspection: Check the pawl or catch mechanism that engages with the ratchet wheel. Ensure it is in good condition, and there is no excessive wear or damage. Replace worn or damaged pawls promptly.

- 5. Alignment: Verify that the ratchet wheel is correctly aligned with the pawl or catch. Misalignment can lead to uneven wear and reduced effectiveness. Make any necessary adjustments to ensure proper engagement.

- 6. Tightening Fasteners: Periodically check and tighten any fasteners, such as bolts and nuts, that secure the ratchet wheel and its associated components. Loose fasteners can lead to play and affect performance.

- 7. Teeth Replacement: If teeth on the ratchet wheel show signs of significant wear or damage, consider replacing the ratchet wheel or the affected teeth. Damaged teeth can lead to unreliable engagement.

- 8. Corrosion Prevention: In corrosive environments, take measures to prevent rust or corrosion on the ratchet wheel. This may include applying protective coatings or using corrosion-resistant materials.

- 9. Calibration (If Applicable): In applications requiring precise control, consider calibrating the ratchet wheel to ensure it provides the desired incremental movement accurately.

- 10. Safety Check: Ensure that ratchet wheels in safety-critical applications are functioning correctly and have not been compromised in any way. This includes systems in vehicles, safety equipment, and emergency mechanisms.

- 11. Replacement: As ratchet wheels age and show significant wear, it’s advisable to replace them to maintain the reliability and safety of the system.

Regular maintenance and inspection of ratchet wheels are essential to prevent unexpected failures, ensure proper engagement, and extend their service life. Following these maintenance practices helps maintain the optimal functionality and reliability of ratchet wheels in mechanical systems.

Can you provide insights into the importance of proper installation and alignment of ratchet wheels?

The proper installation and alignment of ratchet wheels are of utmost importance for ensuring their functionality, longevity, and safety in mechanical systems. Here are key insights into why proper installation and alignment matter:

- 1. Precision and Efficiency: Correct installation and alignment ensure that the ratchet wheel engages smoothly with the pawl or catch mechanism. Proper alignment minimizes friction and maximizes the efficiency of controlled motion, allowing for precise and repeatable adjustments.

- 2. Preventing Premature Wear: Misaligned or improperly installed ratchet wheels can experience uneven wear on their teeth. This can lead to premature wear and decreased service life. Proper alignment distributes loads evenly, reducing the risk of wear and damage.

- 3. Safety Considerations: In safety-critical applications, such as emergency stop systems, the alignment of ratchet wheels is vital. Misalignment can compromise the safety of these systems, leading to unintended operation or failure to engage when needed. Proper alignment ensures reliable safety mechanisms.

- 4. Avoiding Slippage: Correct alignment ensures that the pawl or catch securely engages with the ratchet wheel’s teeth. Improper alignment can result in slippage, where the wheel fails to hold its position or lock as intended. This can be hazardous in applications requiring stability and security.

- 5. Reducing Maintenance Costs: Misaligned ratchet wheels are more likely to require frequent maintenance and replacement. Properly aligned ratchet wheels experience less wear and stress, leading to longer service intervals and reduced maintenance costs over time.

- 6. Enhancing Durability: Well-aligned ratchet wheels are more durable and can withstand higher loads and forces. This durability is essential in applications where the ratchet wheel is subjected to heavy use or challenging conditions.

- 7. Consistency in Operations: Properly installed and aligned ratchet wheels contribute to consistent and repeatable operations. Whether in manufacturing, assembly, or other tasks, consistency is critical for achieving desired outcomes and quality standards.

- 8. Minimizing Vibration and Noise: Misalignment can lead to unwanted vibrations and noise in mechanical systems. Proper alignment reduces these disturbances, contributing to a quieter and smoother operation.

- 9. Compliance with Specifications: Many industries have specific standards and regulations governing the installation and alignment of critical components like ratchet wheels. Proper alignment ensures compliance with these standards and ensures that the system operates as intended.

In summary, proper installation and alignment of ratchet wheels are essential for precision, efficiency, safety, and overall system performance. Investing time and care in the initial installation process pays off in terms of reliability, reduced maintenance, and improved safety in mechanical systems.

Can you explain the primary purpose and applications of ratchet wheels in various industries?

Ratchet wheels serve a primary purpose in various industries by enabling unidirectional motion, preventing backward movement, and offering precise control. Their applications are diverse and include the following:

- 1. Automotive Industry: Ratchet wheels are integral to automotive applications, such as handbrakes and vehicle jacks. Handbrakes use ratchet mechanisms to securely hold a vehicle in place, preventing it from rolling when parked on an incline. Vehicle jacks employ ratchet mechanisms for controlled lifting and lowering of vehicles during maintenance or tire changes.

- 2. Construction and Engineering: Construction and engineering equipment often feature ratchet mechanisms. Ratchet straps and tie-downs are used for securing loads on trucks and trailers. Additionally, ratchet wrenches and torque wrenches provide precise control in construction and assembly tasks, allowing for incremental tightening or loosening of bolts and fasteners.

- 3. Manufacturing and Assembly: Ratchet mechanisms are employed in manufacturing and assembly processes where controlled movement is essential. This includes machinery used in factories for precision tasks like fastening, clamping, or incrementally advancing components on an assembly line.

- 4. Medical Devices: The medical industry utilizes ratchet wheels in various instruments and devices. For instance, surgical instruments may feature ratchet mechanisms to control the movement of specific components, allowing surgeons to perform delicate procedures with precision.

- 5. Material Handling: In material handling equipment such as winches, hoists, and cranes, ratchet wheels ensure the controlled lifting and lowering of heavy loads. They contribute to safety and prevent unintended load movement, making them crucial in industries like construction, manufacturing, and logistics.

- 6. Consumer Products: Ratchet mechanisms are found in many consumer products. A common example is a retractable tape measure, where a ratchet wheel allows the tape to be extended and then locked in place at the desired length. Similarly, many hand tools like screwdrivers and pliers feature ratchet mechanisms for efficient and continuous rotation in one direction.

- 7. Aerospace and Aviation: Ratchet wheels are used in aerospace and aviation applications for tasks like securing cargo in aircraft, controlling movements in cockpit instruments, and ensuring the proper operation of various components within the aircraft.

- 8. Marine and Boating: Marine equipment often employs ratchet mechanisms in winches and pulleys for controlling sails, anchors, and other rigging. They enable sailors to adjust sail tension and anchor position with precision.

- 9. Sports and Recreation: Ratchet mechanisms are used in sports and recreational equipment, such as bike gears and fishing reels. They provide controlled motion and prevent backward movement, enhancing the user experience and safety.

Ratchet wheels are versatile components that find applications in an array of industries, improving safety, control, and efficiency across various mechanical systems.

editor by CX 2024-01-16

many projects that included varied sizes of custom made worm gears to print requirements.

many projects that included varied sizes of custom made worm gears to print requirements. can get this product at marketplace leading prices.

can get this product at marketplace leading prices. extremely strong and light-weight. They are are .100” thick and accept regular .25” (1/4”) metallic or plastic chain.

extremely strong and light-weight. They are are .100” thick and accept regular .25” (1/4”) metallic or plastic chain. high-grade electricity transm

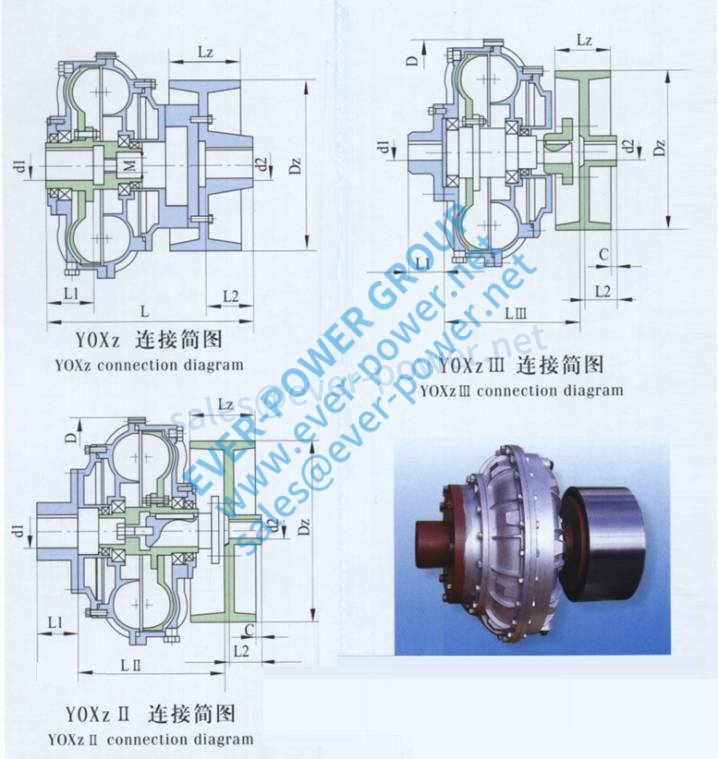

high-grade electricity transm id-Couplings.jpg]#ission technologies, braking and cooling methods, and hydraulic factors.

id-Couplings.jpg]#ission technologies, braking and cooling methods, and hydraulic factors. a more substantial pitch diameter than before with this adjustment. Meet every need in your market by slowing the machinery right down to a specific rate. Simply raise the space between your two discs, which decreases the belt’s motion. At EVER-POWER, our adjustable pulleys give you the necessary adaptability to refine your machinery and move forward with a productive day.

a more substantial pitch diameter than before with this adjustment. Meet every need in your market by slowing the machinery right down to a specific rate. Simply raise the space between your two discs, which decreases the belt’s motion. At EVER-POWER, our adjustable pulleys give you the necessary adaptability to refine your machinery and move forward with a productive day. why.

why. Name:

Name: the timing belt used to operate a vehicle the camshafts within an car or motorcycle engine.

the timing belt used to operate a vehicle the camshafts within an car or motorcycle engine. be in alignment.

be in alignment. the laboratory or anywhere a low vacuum is needed; typically give both vacuum and pressure features. Use tough vacuum pumps (or roughing pumps) for laboratory and industrial applications requiring an even of vacuum less than 10-3 Torr. Use high vacuum pressure pumps when you need vacuums greater than 10-3 Torr. Also, consider the free-air capacity needed (the bigger the free air capacity, the faster it will evacuate the chamber) and whether you need a lubricated (oiled) or non-lubricated (dried out or oilless) pump. Lubricated pumps offer higher capacities, higher vacuum amounts, and lower sound, but can contaminate the machine and require more maintenance.

the laboratory or anywhere a low vacuum is needed; typically give both vacuum and pressure features. Use tough vacuum pumps (or roughing pumps) for laboratory and industrial applications requiring an even of vacuum less than 10-3 Torr. Use high vacuum pressure pumps when you need vacuums greater than 10-3 Torr. Also, consider the free-air capacity needed (the bigger the free air capacity, the faster it will evacuate the chamber) and whether you need a lubricated (oiled) or non-lubricated (dried out or oilless) pump. Lubricated pumps offer higher capacities, higher vacuum amounts, and lower sound, but can contaminate the machine and require more maintenance.  of the standard tests.

of the standard tests. to increase backlash.

to increase backlash.  move back and forth once, it is readily apparent that the input swiftness will determine the amount of strokes or urgings the clutches supply the output shaft each and every minute.

move back and forth once, it is readily apparent that the input swiftness will determine the amount of strokes or urgings the clutches supply the output shaft each and every minute. faster but doesn’t change the sound from the engine as much as a conventional two rate or one rate. This confuses some riders and qualified prospects to a mistaken impression of too little power.

faster but doesn’t change the sound from the engine as much as a conventional two rate or one rate. This confuses some riders and qualified prospects to a mistaken impression of too little power. the right is a specialty customized manufactured

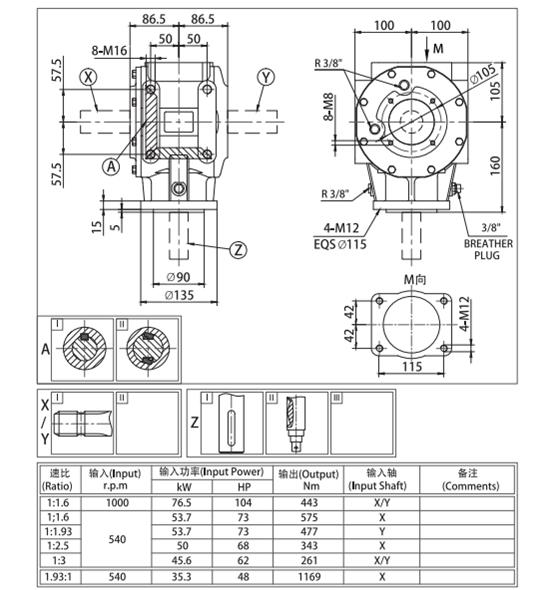

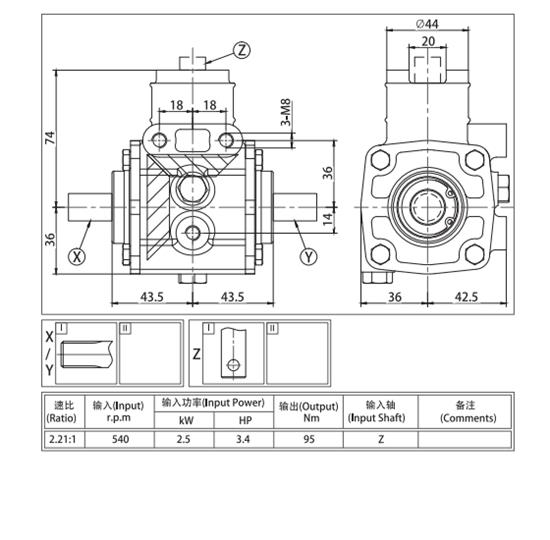

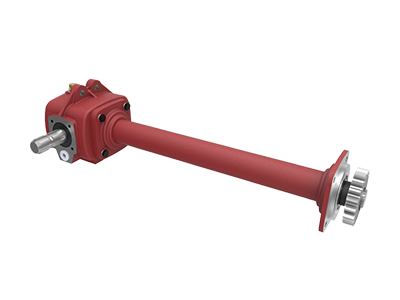

the right is a specialty customized manufactured  Our spiral bevel gearboxes could be given up to four shafts, hollow shaft and with an output torque as high as 1,000 Nm and will end up being fitted with a engine flange with a good coupling for direct mounting of the motor.

Our spiral bevel gearboxes could be given up to four shafts, hollow shaft and with an output torque as high as 1,000 Nm and will end up being fitted with a engine flange with a good coupling for direct mounting of the motor. gear drives are often accessible in the function assistance is ever required.

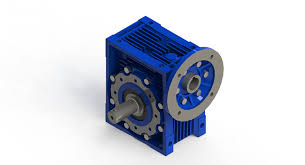

gear drives are often accessible in the function assistance is ever required. to reduce speed and/or transmit higher torque while changing path 90 degrees. Worm gearing is a sliding actions where the work pinion pushes or pulls the worm gear into action. That sliding friction creates heat and lowers the effectiveness ranking. Worm gears can be used in high-torque situations in comparison to other options. They certainly are a common option in conveyor systems since the equipment, or toothed wheel, cannot move the worm. This enables the gearbox motor to continue operation regarding torque overload and also emergency stopping regarding a failure in the system. It also enables worm gearing to handle torque overloads.

to reduce speed and/or transmit higher torque while changing path 90 degrees. Worm gearing is a sliding actions where the work pinion pushes or pulls the worm gear into action. That sliding friction creates heat and lowers the effectiveness ranking. Worm gears can be used in high-torque situations in comparison to other options. They certainly are a common option in conveyor systems since the equipment, or toothed wheel, cannot move the worm. This enables the gearbox motor to continue operation regarding torque overload and also emergency stopping regarding a failure in the system. It also enables worm gearing to handle torque overloads. they could just travel in

they could just travel in  save money and time when identifying and purchasing gears. These pitch templates can be purchased in nine sets to recognize all the normal pitch sizes: Diametral Pitch “DP”, Circular Pitch “CP”, External Involute Splines, Metric Module “MOD”, Stub Tooth, Great Pitches, Coarse Pitches and Uncommon Pitches. Make reference to the section on GEAR GAGES for catalog numbers when ordering.

save money and time when identifying and purchasing gears. These pitch templates can be purchased in nine sets to recognize all the normal pitch sizes: Diametral Pitch “DP”, Circular Pitch “CP”, External Involute Splines, Metric Module “MOD”, Stub Tooth, Great Pitches, Coarse Pitches and Uncommon Pitches. Make reference to the section on GEAR GAGES for catalog numbers when ordering. software, water pump, floor polisher, pickup truck lift, salt spreader, stair lift, hospital bed

software, water pump, floor polisher, pickup truck lift, salt spreader, stair lift, hospital bed low-torque; the addition of a worm drive increases the range of applications that it might be suitable for, especially when the worm drive’s compactness is known as.

low-torque; the addition of a worm drive increases the range of applications that it might be suitable for, especially when the worm drive’s compactness is known as. effective answer for power transmitting applications requiring high-ratio swiftness reduction in a restricted space using correct angle (90°), non-intersecting shafts. When properly used, worms and worm gears provide the smoothest, quietest form of gearing.

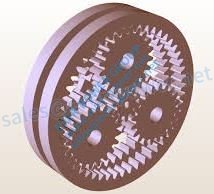

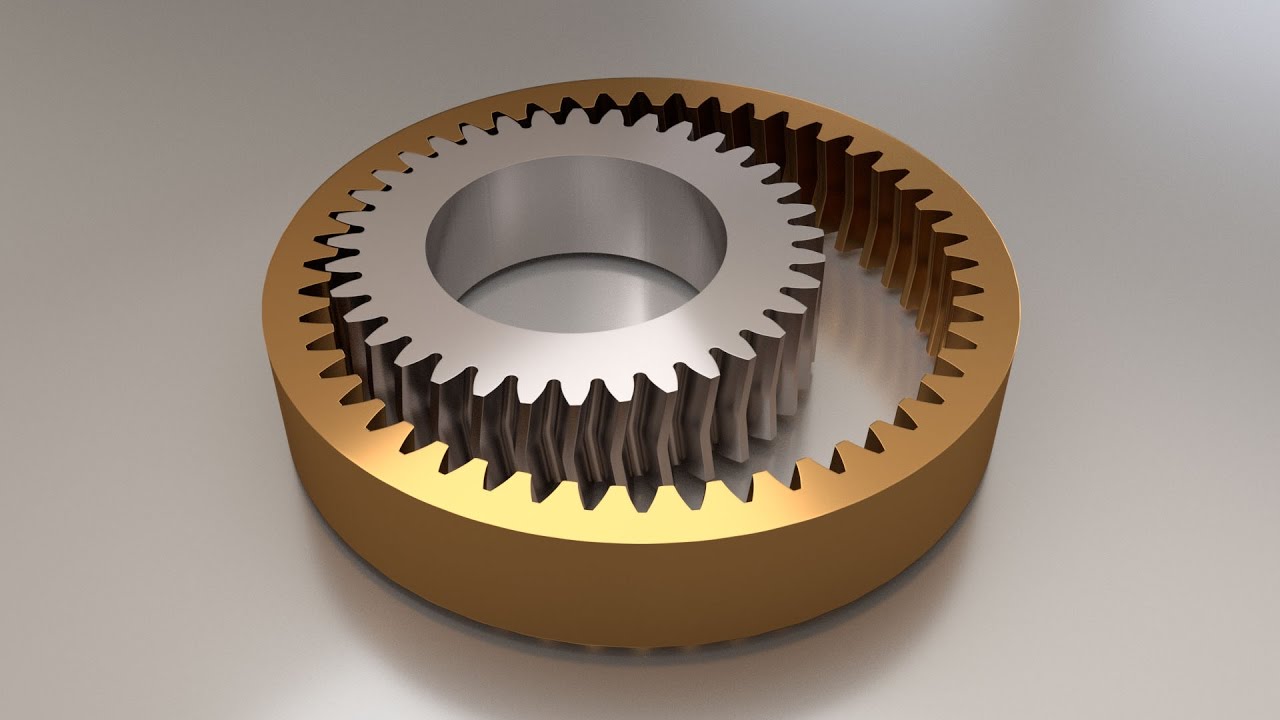

effective answer for power transmitting applications requiring high-ratio swiftness reduction in a restricted space using correct angle (90°), non-intersecting shafts. When properly used, worms and worm gears provide the smoothest, quietest form of gearing. good spur gear in which the tooth are machined on the internal circumference of an annular wheel, these mesh with the exterior teeth of a small pinion. Both tires revolve in the same course. Internal gears have a much better load carrying capability than an external spur equipment. They are safer used because the teeth will be guarded. They are generally applied to bicycle gear changing pumps, system and planetary gear reducers.

good spur gear in which the tooth are machined on the internal circumference of an annular wheel, these mesh with the exterior teeth of a small pinion. Both tires revolve in the same course. Internal gears have a much better load carrying capability than an external spur equipment. They are safer used because the teeth will be guarded. They are generally applied to bicycle gear changing pumps, system and planetary gear reducers. than the central

than the central of a solid or hollow result shaft and show an adjustable mounting placement. Both the SW-1 and the SW-5, nevertheless, can endure shock loading much better than other reduction gearbox styles, making them well suited for demanding applications.

of a solid or hollow result shaft and show an adjustable mounting placement. Both the SW-1 and the SW-5, nevertheless, can endure shock loading much better than other reduction gearbox styles, making them well suited for demanding applications. tranny of higher horsepower amounts than are possible with standard cast iron products. Extra heavy aspect plates connect the worm and equipment shaft bearing supports, assuring proper meshing of the gear under all load conditions. In smaller sizes, fabricated steel reducers are interchangeable with Ever-Power standard cast iron reducers.

tranny of higher horsepower amounts than are possible with standard cast iron products. Extra heavy aspect plates connect the worm and equipment shaft bearing supports, assuring proper meshing of the gear under all load conditions. In smaller sizes, fabricated steel reducers are interchangeable with Ever-Power standard cast iron reducers. the torque output will reduce. Gear drive selection elements include: shaft orientation, rate ratio, design type, nature of load, gear ranking, environment, mounting position, working temperature spectrum, and lubrication.

the torque output will reduce. Gear drive selection elements include: shaft orientation, rate ratio, design type, nature of load, gear ranking, environment, mounting position, working temperature spectrum, and lubrication. more than a few seconds at a time.

more than a few seconds at a time. so a position can be kept even when power is not applied. The precision ground 3/8” stainless steel output shaft is supported by dual 3/8” ABEC 5 ball bearings to support lots from any orientation. The ¼” ABS plastic and aluminum structure offers a rigid framework without adding unnecessary fat and is very easily mounted to any flat surface by utilizing the base mounting tabs. Our Regular Spur Gear motors will continue to work with this gearbox (electric motor marketed separately). The Vertical Shaft Worm-Drive Gearbox is ideal for turn-tables, time-lapse systems and low-acceleration applications that want high precision and torque.

so a position can be kept even when power is not applied. The precision ground 3/8” stainless steel output shaft is supported by dual 3/8” ABEC 5 ball bearings to support lots from any orientation. The ¼” ABS plastic and aluminum structure offers a rigid framework without adding unnecessary fat and is very easily mounted to any flat surface by utilizing the base mounting tabs. Our Regular Spur Gear motors will continue to work with this gearbox (electric motor marketed separately). The Vertical Shaft Worm-Drive Gearbox is ideal for turn-tables, time-lapse systems and low-acceleration applications that want high precision and torque.  the emphasis is on space effectiveness.

the emphasis is on space effectiveness. and helical worm gearboxes / geared motors (S and SS)

and helical worm gearboxes / geared motors (S and SS) gear reducers, quickness reducers, equipment drives, and gearmotors. All terms can be used more or less interchangeably. Please be aware that the inbound links for our little gear drives include details on the full range of framework sizes for that series or design.

gear reducers, quickness reducers, equipment drives, and gearmotors. All terms can be used more or less interchangeably. Please be aware that the inbound links for our little gear drives include details on the full range of framework sizes for that series or design. specific match. And the tighter fit means much less play in the gear teeth, which is the trigger of backlash to begin with. Of training course, precision gears are more expensive, but if the application demands high accuracy, after that precision gearing could be the way to go.

specific match. And the tighter fit means much less play in the gear teeth, which is the trigger of backlash to begin with. Of training course, precision gears are more expensive, but if the application demands high accuracy, after that precision gearing could be the way to go. repeatedly engages the worm gear, the materials of the worm has to be considerably harder than that of the wheel. Because of this, worms are typically produced from metal and worm wheels are typically created from bronze alloys. It’s quite common to harden and grind worms specifically when they are going to be used under excessive load or working at substantial speeds such as inside a reduction drive gearbox.

repeatedly engages the worm gear, the materials of the worm has to be considerably harder than that of the wheel. Because of this, worms are typically produced from metal and worm wheels are typically created from bronze alloys. It’s quite common to harden and grind worms specifically when they are going to be used under excessive load or working at substantial speeds such as inside a reduction drive gearbox. standard for food machinery.

standard for food machinery. quickness reducers are mechanical swiftness reduction equipment used in automation control systems.

quickness reducers are mechanical swiftness reduction equipment used in automation control systems. they are a type of bevel gear, bevel gears have some basic features, such as spur gears, helical gears, and zero-tooth equipment types.

they are a type of bevel gear, bevel gears have some basic features, such as spur gears, helical gears, and zero-tooth equipment types. Input & Output Shafts for Worm Gearboxes

Input & Output Shafts for Worm Gearboxes email us. The application info will be reviewed by our engineers, who will recommend the best solution for your application.

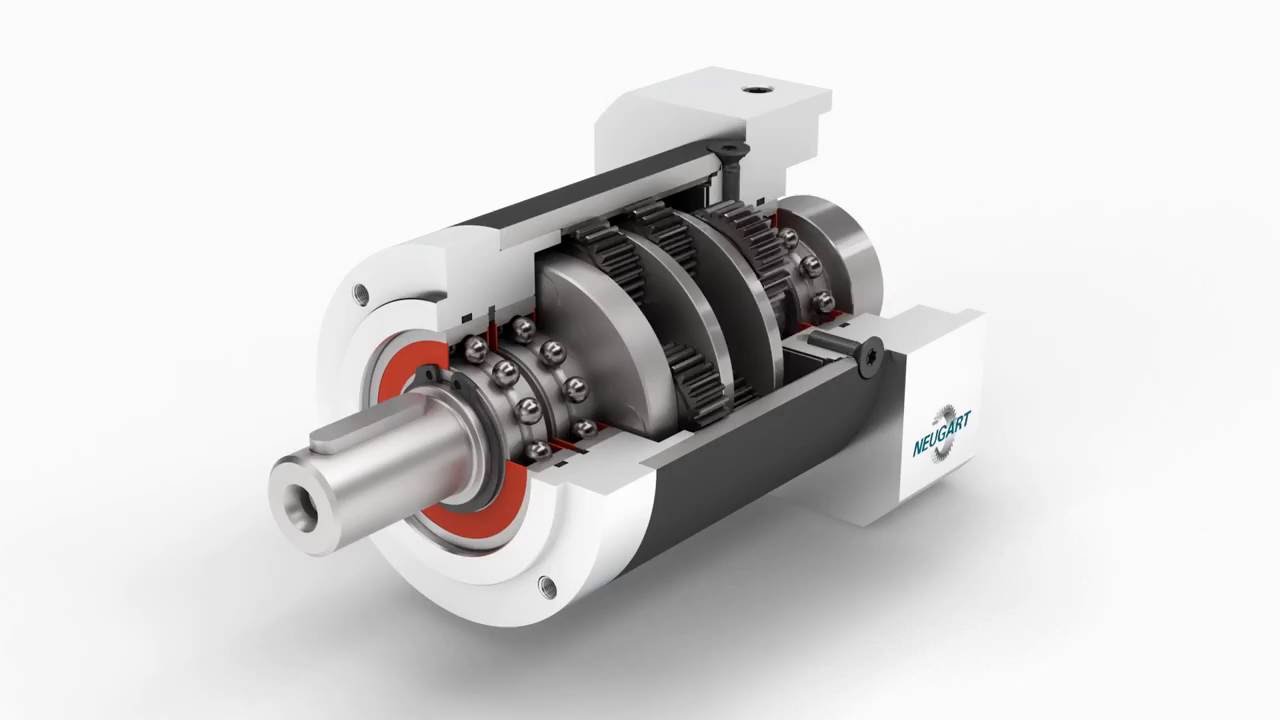

email us. The application info will be reviewed by our engineers, who will recommend the best solution for your application. angle bevel gearbox combines the top features of our correct angle worm and planetary inline reducers. With a solid and efficient correct angle configuration, our right angle planetary gearboxes offer a robust solution. The proper angle bevel gearbox will come in 18 ratios ranging from 5:1 to 1000:1, in fact it is back-drivable at all ratios.

angle bevel gearbox combines the top features of our correct angle worm and planetary inline reducers. With a solid and efficient correct angle configuration, our right angle planetary gearboxes offer a robust solution. The proper angle bevel gearbox will come in 18 ratios ranging from 5:1 to 1000:1, in fact it is back-drivable at all ratios. helical gears, but its helix angle is typically comparatively larger) and its body is normally quite lengthy in the axial path. The gears in these gearboxes could be right or left-handed depending upon the purpose.

helical gears, but its helix angle is typically comparatively larger) and its body is normally quite lengthy in the axial path. The gears in these gearboxes could be right or left-handed depending upon the purpose. tail edge of the tooth transmitting power from the input and the leading edge of the immediately following one. The gap is essential for gears to mesh with one another without getting stuck and to offer lubrication within the casing. On the drawback, the mechanical enjoy is associated with significant motion losses, preventing a motor from reaching its optimal performance. To begin with, the losses influence negatively performance and precision.

tail edge of the tooth transmitting power from the input and the leading edge of the immediately following one. The gap is essential for gears to mesh with one another without getting stuck and to offer lubrication within the casing. On the drawback, the mechanical enjoy is associated with significant motion losses, preventing a motor from reaching its optimal performance. To begin with, the losses influence negatively performance and precision. and so forth. Furthermore, we can produce personalized variators, geared motors, electrical motors and other hydraulic items according to clients’ drawings.

and so forth. Furthermore, we can produce personalized variators, geared motors, electrical motors and other hydraulic items according to clients’ drawings. technically advanced, high velocity, low backlash servo software planetary gearbox. Our Break through patented technology (over 6 patents), supplies the client with the the best possible high precision helical reducer at a reasonable price and emerges with the only suggestion to toe 5-12 months warranty in the market today, including the seals and bearings. Our company slogan is TRUTHFUL RESPONSIBLE CREATIVE. The primary focus in daily operation is quality. We satisfaction ourselves on our dedication to quality; our duty, is customer satisfaction. We are constantly improving processes, finding appropriate and effective methods to provide customers new solutions for hard applications, and developing services.

technically advanced, high velocity, low backlash servo software planetary gearbox. Our Break through patented technology (over 6 patents), supplies the client with the the best possible high precision helical reducer at a reasonable price and emerges with the only suggestion to toe 5-12 months warranty in the market today, including the seals and bearings. Our company slogan is TRUTHFUL RESPONSIBLE CREATIVE. The primary focus in daily operation is quality. We satisfaction ourselves on our dedication to quality; our duty, is customer satisfaction. We are constantly improving processes, finding appropriate and effective methods to provide customers new solutions for hard applications, and developing services.  up a hill and around a tree.

up a hill and around a tree. where nhsg = the number of followers or rollers in the fixed housing and nops = the quantity for followers or rollers in the sluggish velocity output shaft (flange).

where nhsg = the number of followers or rollers in the fixed housing and nops = the quantity for followers or rollers in the sluggish velocity output shaft (flange). with an assortment of predefined roller and raceway crowns, or with a measured crown.

with an assortment of predefined roller and raceway crowns, or with a measured crown. reducer.

reducer. Using a gearhead with a servo motor or using an integrated gearmotor can enable the use of a smaller motor, thereby reducing the machine size and price. There are three primary advantages of going with gears, each of which can enable the use of smaller sized motors and drives and therefore lower total system cost:

Using a gearhead with a servo motor or using an integrated gearmotor can enable the use of a smaller motor, thereby reducing the machine size and price. There are three primary advantages of going with gears, each of which can enable the use of smaller sized motors and drives and therefore lower total system cost: In order to center the device before the install, stick to these easy steps:

In order to center the device before the install, stick to these easy steps: in relatively brief periods

in relatively brief periods systems can also be tailor-made to offer movements to either direction. This is achieved through integrating two or more motors on either end of the conveyor system.

systems can also be tailor-made to offer movements to either direction. This is achieved through integrating two or more motors on either end of the conveyor system. moderate loads and speeds, it is extremely easy to restoration and install. Something vital that you note when setting up and using metal detachable chain is that the closed end of the tab should always end up being towards the sprocket. We stock both painted and non-painted SDC chains so when ordering please specify which series you are interested in.

moderate loads and speeds, it is extremely easy to restoration and install. Something vital that you note when setting up and using metal detachable chain is that the closed end of the tab should always end up being towards the sprocket. We stock both painted and non-painted SDC chains so when ordering please specify which series you are interested in. the sprockets. Silent chains drives are not truly silent. The links in a silent chain drive, however, build relationships the sprocket the teeth with little influence or sliding, and consequently a silent chain creates less vibrations and sound than other chains. The amount of noise generated by a silent chain drive is dependent of many factors including sprocket size, swiftness, lubrication, load, and drive support. A web link belt silent chain includes removable links became a member of by rivets or interlocking tabs. These chains offer the advantage of installation without dismantling drive elements, reducing inventory, and increasing temperature ranges

the sprockets. Silent chains drives are not truly silent. The links in a silent chain drive, however, build relationships the sprocket the teeth with little influence or sliding, and consequently a silent chain creates less vibrations and sound than other chains. The amount of noise generated by a silent chain drive is dependent of many factors including sprocket size, swiftness, lubrication, load, and drive support. A web link belt silent chain includes removable links became a member of by rivets or interlocking tabs. These chains offer the advantage of installation without dismantling drive elements, reducing inventory, and increasing temperature ranges Standard Roller Chains. These chains are designed for general usage.

Standard Roller Chains. These chains are designed for general usage. standards you demand from your tools, such as fighting off debris accumulation and acclimating to nearly every temperature alter. Agricultural roller chain goes through extensive examining and quality checks before it finds your farm. Try our agricultural smooth link chain for easy operations every day. If you want trusted agricultural conveyor chain parts in a hurry.

standards you demand from your tools, such as fighting off debris accumulation and acclimating to nearly every temperature alter. Agricultural roller chain goes through extensive examining and quality checks before it finds your farm. Try our agricultural smooth link chain for easy operations every day. If you want trusted agricultural conveyor chain parts in a hurry. excess axial forces total little more than an inconvenience. Gearbox designers will often upsize the bearings to support the additional forces.

excess axial forces total little more than an inconvenience. Gearbox designers will often upsize the bearings to support the additional forces. equipment motor has the ability to handle numerous load requirements; the more gear stages (stacks), the bigger the strain distribution and torque transmission.

equipment motor has the ability to handle numerous load requirements; the more gear stages (stacks), the bigger the strain distribution and torque transmission. (-40°C)

(-40°C) All fasteners are stainless steel. Hard anodized aluminum or 316 Stainless housings are available. Customizing for other than NEMA motors or your specific application is quickly done.

All fasteners are stainless steel. Hard anodized aluminum or 316 Stainless housings are available. Customizing for other than NEMA motors or your specific application is quickly done. and the top speed gear is obtained. When the left dog clutch meshes with the second gear on the main shaft, the next speed gear is achieved. Similarly, by sliding the right-hand dog clutch left and right, the first speed gear and reverse gear are attained respectively In this type of gearbox, because all of the gears are in continuous mesh, they are secure from being damaged and unpleasant grinding audio does not happen while engaging and disengaging them.

and the top speed gear is obtained. When the left dog clutch meshes with the second gear on the main shaft, the next speed gear is achieved. Similarly, by sliding the right-hand dog clutch left and right, the first speed gear and reverse gear are attained respectively In this type of gearbox, because all of the gears are in continuous mesh, they are secure from being damaged and unpleasant grinding audio does not happen while engaging and disengaging them. robust and torsion resistant casing so as to ensure long service life standards. The housing is constructed of quality close grained Grey Cast Iron that is proportioned to ensure proper radiation of heat generated when the models are operated at optimum capacity. Further, ideal ribs are placed under bearing seats for high strength with walls of enough thickness to withstand many severe stresses faced during operation. Additional, we also hold expertise in providing housing in cast metal/fabricated steel finish if required.

robust and torsion resistant casing so as to ensure long service life standards. The housing is constructed of quality close grained Grey Cast Iron that is proportioned to ensure proper radiation of heat generated when the models are operated at optimum capacity. Further, ideal ribs are placed under bearing seats for high strength with walls of enough thickness to withstand many severe stresses faced during operation. Additional, we also hold expertise in providing housing in cast metal/fabricated steel finish if required. and permits precise positioning tasks.

and permits precise positioning tasks. of electric motor size and type which best satisfies the customer’s requirements and application.

of electric motor size and type which best satisfies the customer’s requirements and application. way of acceleration and deceleration, the instantaneous torque borne by the output shaft of the Planetary reduction drive exceeds 2 times of its rated output torque, and this kind of acceleration and deceleration can be too frequent, which will eventually make Planetary reduction drive break the shaft.

way of acceleration and deceleration, the instantaneous torque borne by the output shaft of the Planetary reduction drive exceeds 2 times of its rated output torque, and this kind of acceleration and deceleration can be too frequent, which will eventually make Planetary reduction drive break the shaft. does not accommodate parallel displacement of shafts but does accommodate angular misalignment. This sort of couplings are primarily utilized for “floating shaft” programs.

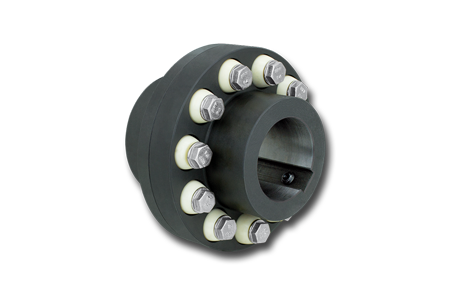

does not accommodate parallel displacement of shafts but does accommodate angular misalignment. This sort of couplings are primarily utilized for “floating shaft” programs. to as a gear-kind versatile, or versatile coupling. The solitary joint allows for minor misalignments this kind of as set up errors and changes in shaft alignment because of to working situations. These kinds of equipment couplings are generally limited to angular misalignments of one/4â1/2°.

to as a gear-kind versatile, or versatile coupling. The solitary joint allows for minor misalignments this kind of as set up errors and changes in shaft alignment because of to working situations. These kinds of equipment couplings are generally limited to angular misalignments of one/4â1/2°. suppliers now.

suppliers now. ore on it based

ore on it based  mostly on the fluid in the outer load immediately modify the working cavity quantity, therefore play a function overload defense.

mostly on the fluid in the outer load immediately modify the working cavity quantity, therefore play a function overload defense. %20coupling2.jpg]#design

%20coupling2.jpg]#design  conveyors, crushers, fanatics, pumps and blowers. They are utilised in numerous industries such as energy technology, steel Era, mining and quarrying, petrochemical and foodstuff producing. They have offered over 70 several several years of dependable successful procedure, and nonetheless give the engineer with a reliable approach of commencing an doing work hefty industrial tools.

conveyors, crushers, fanatics, pumps and blowers. They are utilised in numerous industries such as energy technology, steel Era, mining and quarrying, petrochemical and foodstuff producing. They have offered over 70 several several years of dependable successful procedure, and nonetheless give the engineer with a reliable approach of commencing an doing work hefty industrial tools. upon request

upon request or 450 Nm.

or 450 Nm. Furthermore, 12 M4 holes in it also allow to be used as the plate in Ever-power platform.

Furthermore, 12 M4 holes in it also allow to be used as the plate in Ever-power platform. x 4 x 5 = 60). Inside our example above, the 3,450 rpm electric motor would have its speed reduced to 57.5 rpm by using a 60:1 gearbox. The 10 lb-in electric motor torque would be risen to 600 lb-in (before efficiency losses).

x 4 x 5 = 60). Inside our example above, the 3,450 rpm electric motor would have its speed reduced to 57.5 rpm by using a 60:1 gearbox. The 10 lb-in electric motor torque would be risen to 600 lb-in (before efficiency losses). machines requiring high accuracy positioning.

machines requiring high accuracy positioning.

almost everything seems normal, attempt changing the gear-mesh. This is carried out with the mylar “gaskets” that sit among the primary gearbox circumstance and the enter/output caps. Consider introducing or taking away some of these spacers until finally your gears have about one/8″-one/four” of free enjoy. Pros can buy replacements ($1-two) in various thicknesses, but we suggest the swift and filthy method of chopping your possess out of a sheet of mylar.

almost everything seems normal, attempt changing the gear-mesh. This is carried out with the mylar “gaskets” that sit among the primary gearbox circumstance and the enter/output caps. Consider introducing or taking away some of these spacers until finally your gears have about one/8″-one/four” of free enjoy. Pros can buy replacements ($1-two) in various thicknesses, but we suggest the swift and filthy method of chopping your possess out of a sheet of mylar. ISO 606, ready to install

ISO 606, ready to install high input speeds and a little package size with an excellent price/performance ratio.

high input speeds and a little package size with an excellent price/performance ratio. uniform.

uniform. and non-standard products available. We are able to produce as per your drawing or sample. Material can be standard or as per your special request. If you choose us, you choose reliable.

and non-standard products available. We are able to produce as per your drawing or sample. Material can be standard or as per your special request. If you choose us, you choose reliable. tapered roller bearings are standard for the ISO Flanged Reducers.

tapered roller bearings are standard for the ISO Flanged Reducers. originally suitable for use in small sprockets, now suitable for a great many other lighter-duty applications

originally suitable for use in small sprockets, now suitable for a great many other lighter-duty applications variety of industrial and mobile applications.

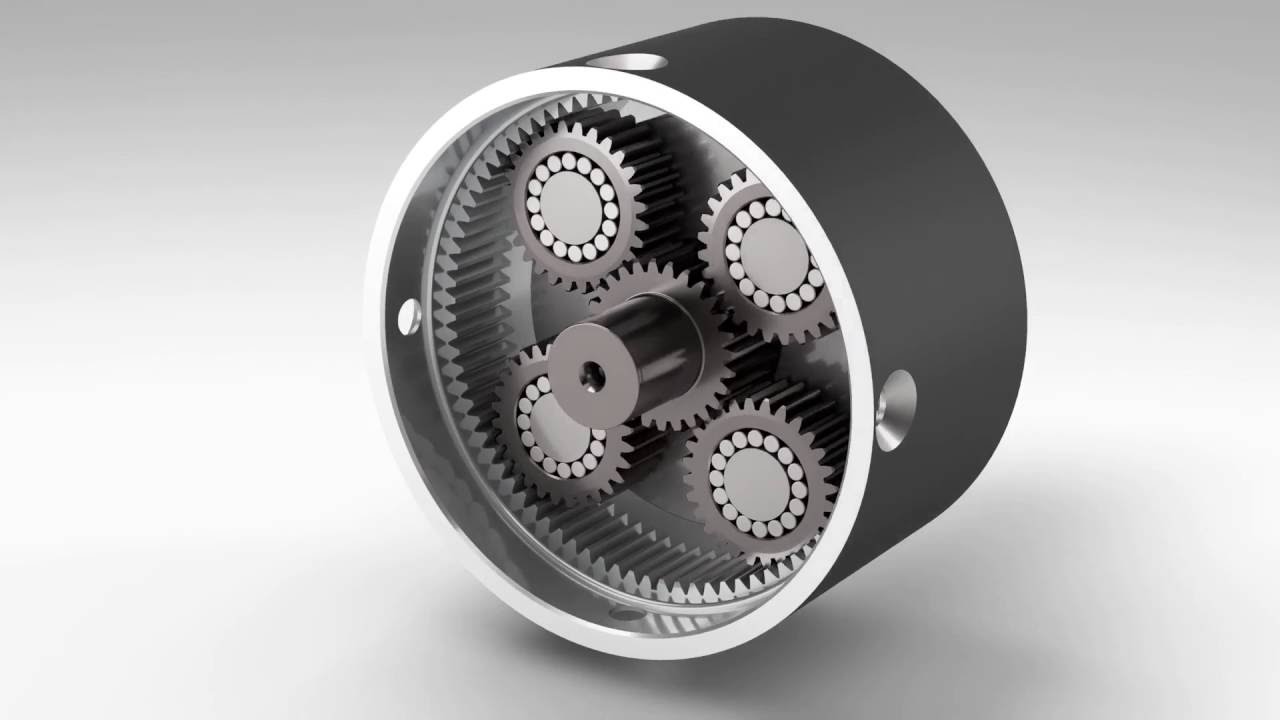

variety of industrial and mobile applications. generating torque. Multiple contact factors across the planetary gear teach permits higher torque generation compared to one of our spur gear motors. Subsequently, an EP planetary equipment motor has the capacity to handle different load requirements; the more equipment stages (stacks), the higher the strain distribution and torque transmitting.

generating torque. Multiple contact factors across the planetary gear teach permits higher torque generation compared to one of our spur gear motors. Subsequently, an EP planetary equipment motor has the capacity to handle different load requirements; the more equipment stages (stacks), the higher the strain distribution and torque transmitting. expensive. As an automotive supplier and industrial partner, you can expect solutions that help keep people safer and healthier. We help secure the environment and present individuals more opportunities to shape their own future.

expensive. As an automotive supplier and industrial partner, you can expect solutions that help keep people safer and healthier. We help secure the environment and present individuals more opportunities to shape their own future. provides an example and a formulation for dealing with inertia in gearbox selection.

provides an example and a formulation for dealing with inertia in gearbox selection. every Original Equipment Manufacturer worldwide to create products for new automobiles as they are being developed. These solid relationships as well as Ever-power commitment to continuous innovation allow us to provide a complete line of OE quality products for the Aftermarket. From Timing Belts to Micro-V AT Belts, Tensioners and Hose, for both import and domestic vehicles, install with confidence, install Ever-power.

every Original Equipment Manufacturer worldwide to create products for new automobiles as they are being developed. These solid relationships as well as Ever-power commitment to continuous innovation allow us to provide a complete line of OE quality products for the Aftermarket. From Timing Belts to Micro-V AT Belts, Tensioners and Hose, for both import and domestic vehicles, install with confidence, install Ever-power. motor flanges

motor flanges between cords and other sections. This way, heat build-up is reduced, extending belt life.

between cords and other sections. This way, heat build-up is reduced, extending belt life. Hypoid versus. Worm Gears: A More AFFORDABLE Right-Angle Reducer

Hypoid versus. Worm Gears: A More AFFORDABLE Right-Angle Reducer a simple structure which can be utilized with electrical motors for output rate reduction, huge torque and good capability of enduring overload. This gearbox is an ideal option for working two loads from one motor and extremely serves the objective of operating machinery like conveyors, rotary table, and packaging machinery.

a simple structure which can be utilized with electrical motors for output rate reduction, huge torque and good capability of enduring overload. This gearbox is an ideal option for working two loads from one motor and extremely serves the objective of operating machinery like conveyors, rotary table, and packaging machinery. are setting up some of the highest quality parts obtainable in the automotive aftermarket – all meeting or exceeding the Original Equipment Manufacturer’s specifications.

are setting up some of the highest quality parts obtainable in the automotive aftermarket – all meeting or exceeding the Original Equipment Manufacturer’s specifications. tonnes).

tonnes). gears: Provides higher efficiencies and greater torque capacity in smaller sized sizes.

gears: Provides higher efficiencies and greater torque capacity in smaller sized sizes. brinnell marks that are the effect of a frozen slide are at all times evident on leading and back floors of the cross trunnion.

brinnell marks that are the effect of a frozen slide are at all times evident on leading and back floors of the cross trunnion. shaft to become a flying missile, or it may strike and break a thing that is attached or installed on the trunk of the tractor. Separation of the driveline shaft isn’t a commonly occurring celebration but is most probably to happen when three-point

shaft to become a flying missile, or it may strike and break a thing that is attached or installed on the trunk of the tractor. Separation of the driveline shaft isn’t a commonly occurring celebration but is most probably to happen when three-point  safety mechanisms that must be in location to protect yourself and your investment. The very first thing you notice when looking at a PTO shaft is the plastic material sleeve that encases the entire length of the shaft between your tractor and the attachment, the metal shaft is actually turning inside of this simple protective casing, avoiding curious onlookers from grabbing a higher horsepower turning shaft and seriously doing some damage to their hands and hands. The next thing you might notice may be the bolts and plates that can be found at one end of the shaft, these bolts and plates are the automatic pressure relief system that manufacturers put on them to release pressure if for example a tiller digs partially into hard floor that it could not power through, one of two

safety mechanisms that must be in location to protect yourself and your investment. The very first thing you notice when looking at a PTO shaft is the plastic material sleeve that encases the entire length of the shaft between your tractor and the attachment, the metal shaft is actually turning inside of this simple protective casing, avoiding curious onlookers from grabbing a higher horsepower turning shaft and seriously doing some damage to their hands and hands. The next thing you might notice may be the bolts and plates that can be found at one end of the shaft, these bolts and plates are the automatic pressure relief system that manufacturers put on them to release pressure if for example a tiller digs partially into hard floor that it could not power through, one of two  ISP is exclusively available from Ever-power. It offers a simple method of steering flat steel belts. Users may combine ISP steering with the original belt tracking designs of crowning, flanging, and timing elements to make a synergistic belt tracking system which efficiently and exactly steers the belt to specified tracking parameters.

ISP is exclusively available from Ever-power. It offers a simple method of steering flat steel belts. Users may combine ISP steering with the original belt tracking designs of crowning, flanging, and timing elements to make a synergistic belt tracking system which efficiently and exactly steers the belt to specified tracking parameters. patrons the very best quality selection of Mechanical Coupling.

patrons the very best quality selection of Mechanical Coupling. and worm gears provide the smoothest, quietest type of gearing.

and worm gears provide the smoothest, quietest type of gearing. very best chains by each manufacturer so do not inquire about cheaper chains as we don’t want our customers calling back upset and for that reason we only sell what we believe in and know to be the very best. All of our chain kits also come with a rivet master link for the best safely, quality, and performance.

very best chains by each manufacturer so do not inquire about cheaper chains as we don’t want our customers calling back upset and for that reason we only sell what we believe in and know to be the very best. All of our chain kits also come with a rivet master link for the best safely, quality, and performance. another piece of metal attached to the axle which can consider this axle torque and transfer it further up the frame, thus relieving the dropout itself from currently taking all of the stresses.

another piece of metal attached to the axle which can consider this axle torque and transfer it further up the frame, thus relieving the dropout itself from currently taking all of the stresses. and supports direction control as well as PWM acceleration control. Rated voltage is 12v and can achieve 16RPM.

and supports direction control as well as PWM acceleration control. Rated voltage is 12v and can achieve 16RPM. Ever-power aluminium rear sprockets have already been precision CNC machined to an extremely limited tolerance. With a case hardened primary they provide the ultimate combination of minimal weight, optimum strength and hardness.

Ever-power aluminium rear sprockets have already been precision CNC machined to an extremely limited tolerance. With a case hardened primary they provide the ultimate combination of minimal weight, optimum strength and hardness. which has polypropylene inside links and 304-stainless metal pin links.

which has polypropylene inside links and 304-stainless metal pin links.  replaced a little early. It’ll be less expensive than waiting until following the belt breaks.

replaced a little early. It’ll be less expensive than waiting until following the belt breaks. doubleworm version, with or without the torque limiter, also accumulate, creating a highly versatile drive system.

doubleworm version, with or without the torque limiter, also accumulate, creating a highly versatile drive system.  worm drive gearboxes. Gear reduction boxes feature a gear arrangement in which a equipment in the type of a screw, also known as a worm, meshes with a worm gear. These gears are usually made from bronze and the worms are steel or stainless steel.

worm drive gearboxes. Gear reduction boxes feature a gear arrangement in which a equipment in the type of a screw, also known as a worm, meshes with a worm gear. These gears are usually made from bronze and the worms are steel or stainless steel. Strong and long lasting. – Are designed for horizontal and vertical forces concurrently. These bearings are perfect for moderate acceleration, heavy-duty applications where sturdiness is required.

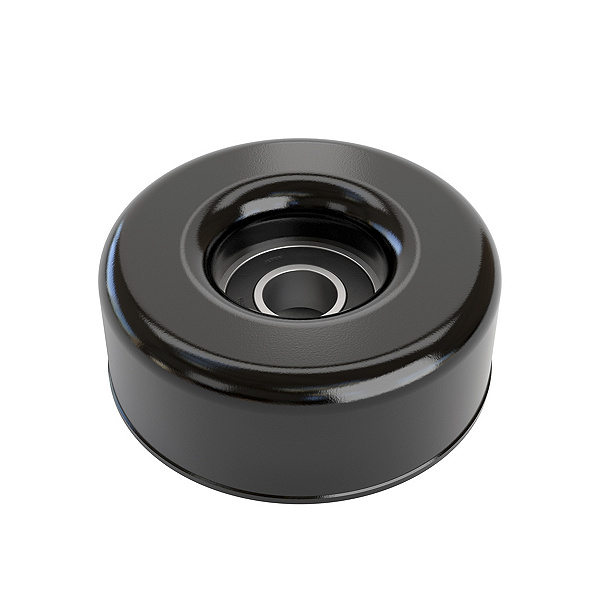

Strong and long lasting. – Are designed for horizontal and vertical forces concurrently. These bearings are perfect for moderate acceleration, heavy-duty applications where sturdiness is required. fact, today, this type of drive mechanisms are those that offer greater efficiency.

fact, today, this type of drive mechanisms are those that offer greater efficiency. also supply special bushings manufactured from other machinable components. Please inquire

also supply special bushings manufactured from other machinable components. Please inquire remember that each host firearm must be examined for baffle alignment via visible inspection before firing.

remember that each host firearm must be examined for baffle alignment via visible inspection before firing.  locks, you simply press the lock down or to the part to ensure that the door is locked effectively and securely. Nevertheless, with vitality locks, you press option and all doors in the vehicle lock simultaneously. The energy of this is through many of things together with your car battery plus your door lock actuator. A door lock

locks, you simply press the lock down or to the part to ensure that the door is locked effectively and securely. Nevertheless, with vitality locks, you press option and all doors in the vehicle lock simultaneously. The energy of this is through many of things together with your car battery plus your door lock actuator. A door lock  to mar the shaft. One piece clamp-on shaft collars simply slide onto the shaft and are guaranteed with a screw. They clamp evenly around the shaft for this reason providing excellent holding vitality. Made of T303 stainless steel which provides excellent corrosion level of resistance. Our shaft collars can be found in several different styles to meet you or your customer’s needs. Climax Steel Products Co. running a business for over 60 years is the leading maker of shaft collars, rigid couplings & keyless locking assemblies. Climax Metals, where fair market pricing and wonderful customer support is our promise for you.

to mar the shaft. One piece clamp-on shaft collars simply slide onto the shaft and are guaranteed with a screw. They clamp evenly around the shaft for this reason providing excellent holding vitality. Made of T303 stainless steel which provides excellent corrosion level of resistance. Our shaft collars can be found in several different styles to meet you or your customer’s needs. Climax Steel Products Co. running a business for over 60 years is the leading maker of shaft collars, rigid couplings & keyless locking assemblies. Climax Metals, where fair market pricing and wonderful customer support is our promise for you. a (little) savings. While the ceramic ball is approximately one-half the pounds of a metal ball the same size, it’s the stiffness that’s important in their performance.

a (little) savings. While the ceramic ball is approximately one-half the pounds of a metal ball the same size, it’s the stiffness that’s important in their performance. cross-section gear rack designs in a

cross-section gear rack designs in a 0.3-0.5mm after precise grinding

0.3-0.5mm after precise grinding to be engaged at the same time as one’s teeth roll across one another.

to be engaged at the same time as one’s teeth roll across one another. with cast iron bushed bore pulley

with cast iron bushed bore pulley relationships every other tooth. Sprockets will have an extended life as chains engage with different teeth every time the rollers rotate (when actual number of the teeth is odd).

relationships every other tooth. Sprockets will have an extended life as chains engage with different teeth every time the rollers rotate (when actual number of the teeth is odd). bearings, pulleys, wheels, etc. Precise combinations vary, based on specific reducer type. What’s common for all combinations-they are intended to transmit power from the electric motor output towards the strain in order to reduce rate and increase torque in a safe and consistent manner.

bearings, pulleys, wheels, etc. Precise combinations vary, based on specific reducer type. What’s common for all combinations-they are intended to transmit power from the electric motor output towards the strain in order to reduce rate and increase torque in a safe and consistent manner. well on virtually any shaft. They’re also long lasting, cost-effective and incredibly simple to use: simply slide the collar into position and tighten the screw to lock it in place.

well on virtually any shaft. They’re also long lasting, cost-effective and incredibly simple to use: simply slide the collar into position and tighten the screw to lock it in place. rapid availability along with optimal reliability and optimum economy within a lifespan of more than 20,000 hours.

rapid availability along with optimal reliability and optimum economy within a lifespan of more than 20,000 hours. of which usually incorporates a gear. Together with attachment holes in both rings, they enable an optimized power transmitting with a simple and quick interconnection between adjacent machine parts. The bearing raceways, in conjunction with the rolling components and cages or spacers, are designed to accommodate loads performing singly or in combination, and in virtually any direction.

of which usually incorporates a gear. Together with attachment holes in both rings, they enable an optimized power transmitting with a simple and quick interconnection between adjacent machine parts. The bearing raceways, in conjunction with the rolling components and cages or spacers, are designed to accommodate loads performing singly or in combination, and in virtually any direction. – tailored precision up to ≤ 2 arcminutes for a number of applications. You profit from rapid availability along with optimal reliability and optimum economy within a lifespan greater than 20,000 hours.

– tailored precision up to ≤ 2 arcminutes for a number of applications. You profit from rapid availability along with optimal reliability and optimum economy within a lifespan greater than 20,000 hours. sale to assembly to practically all servo motors, and the hollow bore result can be utilized to mount output shafts, pinion shafts, or other drive elements.

sale to assembly to practically all servo motors, and the hollow bore result can be utilized to mount output shafts, pinion shafts, or other drive elements. power and larger axial load potential than setscrew collars

power and larger axial load potential than setscrew collars STYLES

STYLES air movements further toward the center of the spirals, the surroundings pockets become smaller, and the surroundings in those pockets gets compressed.

air movements further toward the center of the spirals, the surroundings pockets become smaller, and the surroundings in those pockets gets compressed. lubrication. The drive sleeve is usually supported on anti-friction tapered roller or ball thrust bearings. Rotation of the drive sleeve causes the acme thread lifting screw to translate or rotate, depending upon jack configuration.