Product Description

Product Description

1.Before use, it is necessary to check for any damage or aging, and replace the shear in a timely manner.

2. Do not place your fingers at the edge of the knife to avoid accidents.

3. Do not use excessive force during cutting to avoid damaging the shear or material.

4. During operation, it is important to remain alert, pay attention to safety, and avoid accidents.

5. After use, timely cleaning and maintenance should be carried out to ensure the lifespan and effectiveness of the shear.

In short, the correct use of ratchet cable cutters can not only improve work efficiency, but also ensure operational safety and material quality.

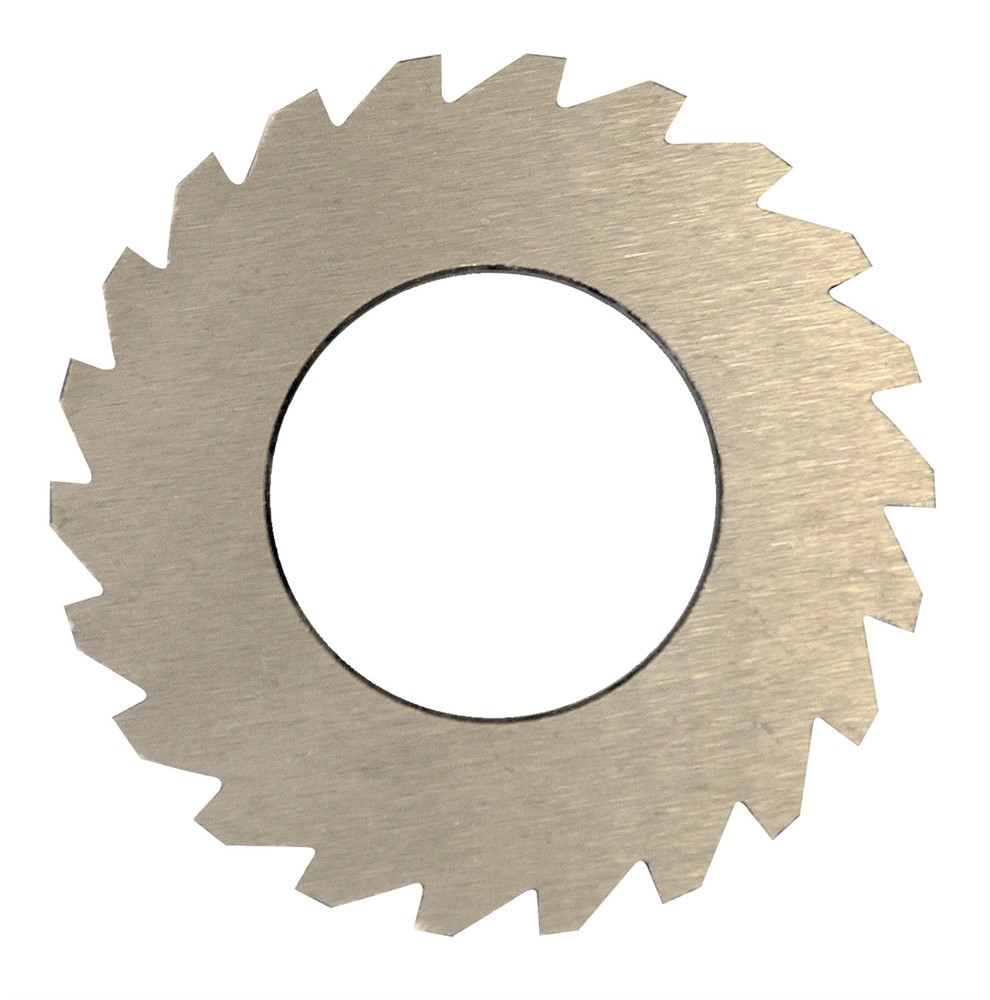

6.Cast blade with long service life

7.The new electric ratchet cutter for stable cutting adopts a composite integrated hard blade design, which is lightweight and strong, ensuring cutting quality; The product is equipped with high-performance motors, which provide CHINAMFG power support during use, ensuring smooth cutting.

| model | XLJ-G-50D |

| voltage | DV18V |

| Cut Material | Copper aluminum wire |

| Charging time | About 2 hours |

| Number of uses | About 100 times |

| weight | 3.6kg |

| Cutting range | Suitable for copper aluminum wires with an outer diameter of less than 70mm |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Condition: | New |

| Automatic Grade: | Automatic |

| Brand: | Yikai |

| Blade Material: | Copper Stranded Wire |

| Charging Time: | About Two Hours |

| Customization: |

Available

|

|

|---|

How do ratchet wheels differ from other types of gears in terms of functionality?

Ratchet wheels differ from other types of gears in terms of functionality primarily due to their unidirectional motion and ability to prevent backward movement. Here are key distinctions between ratchet wheels and other gears:

- 1. Unidirectional Motion: Ratchet wheels are designed to allow motion in only one direction. When force is applied in the desired direction, the ratchet wheel rotates freely, enabling movement. In contrast, traditional gears, such as spur gears or helical gears, transmit motion bidirectionally—both clockwise and counterclockwise.

- 2. Prevention of Backward Movement: The defining feature of ratchet wheels is their ability to prevent backward movement. This is achieved through the engagement of a pawl or catch mechanism with the teeth of the ratchet wheel. The pawl locks the ratchet wheel in place when force is applied in the opposite direction, effectively preventing any reverse motion. Traditional gears do not have this locking capability and allow bidirectional movement without restriction.

- 3. Incremental Motion Control: Ratchet wheels are often used in applications where precise incremental motion control is required. The teeth on a ratchet wheel are typically spaced in a way that allows for controlled, step-by-step movement. This is advantageous in scenarios where precise positioning or adjustments are necessary, such as in ratchet wrenches or fine-tooth ratchet wheels.

- 4. Limited Gear Ratio: Unlike traditional gears that can provide variable gear ratios to change speed and torque, ratchet wheels offer a fixed gear ratio. They are not used for speed reduction or torque amplification but rather for controlled and secure movement in one direction.

- 5. Specialized Applications: Ratchet wheels are commonly found in specific applications where their unidirectional and locking capabilities are crucial. These include hand tools like ratchet wrenches, winches, tie-down straps, handbrakes in vehicles, and more. Traditional gears are used in a broader range of applications where bidirectional motion is needed, such as in machinery, vehicles, and industrial equipment.

In summary, ratchet wheels excel at providing controlled, unidirectional motion and preventing backward movement. They are specialized components used in applications where these characteristics are essential. Traditional gears, on the other hand, are versatile components that transmit motion bidirectionally and are employed in a wide array of mechanical systems for various purposes.

How does the choice of ratchet wheels affect the overall performance and reliability of mechanical systems?

The choice of ratchet wheels plays a significant role in determining the overall performance and reliability of mechanical systems. Here’s how different factors related to ratchet wheel selection impact these aspects:

- 1. Load Capacity: The load capacity of the chosen ratchet wheel must match the intended application. Using a ratchet wheel with insufficient load capacity can lead to premature wear, slippage, and safety risks.

- 2. Material Selection: Ratchet wheels are available in various materials, such as steel, stainless steel, and plastic. The choice of material affects factors like durability, corrosion resistance, and weight. Selecting the appropriate material for the environment and application is critical.

- 3. Tooth Profile and Design: The tooth profile and design of the ratchet wheel impact how well it engages with the pawl or catch. Proper tooth design ensures reliable engagement, reducing the risk of slippage or unintended movement.

- 4. Precision and Tolerance: High-precision ratchet wheels with tight tolerances provide smoother and more consistent operation. Precision is essential in applications where accuracy and repeatability are critical.

- 5. Pawl Compatibility: Ensure that the selected ratchet wheel is compatible with the accompanying pawl or catch mechanism. Incompatibility can lead to issues with engagement and reliability.

- 6. Surface Finish: The surface finish of the ratchet wheel affects friction and wear. A polished or treated surface can reduce friction, extend the service life, and enhance performance.

- 7. Environmental Considerations: Consider the environmental conditions in which the ratchet wheel will operate. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized materials or coatings to maintain reliability.

- 8. Maintenance Requirements: Some ratchet wheels may require more frequent maintenance than others. Understanding the maintenance needs of the chosen ratchet wheel is crucial for long-term reliability.

- 9. Compliance with Standards: Ensure that the selected ratchet wheel complies with industry standards and regulations. Compliance is essential for safety and reliability in specific applications.

- 10. Cost-Benefit Analysis: Consider the cost-effectiveness of the chosen ratchet wheel. While high-quality options may come at a higher price, they often offer better long-term reliability and reduced maintenance costs.

- 11. Application-Specific Features: Some ratchet wheels may offer features tailored to specific applications, such as noise reduction or enhanced security. Choosing a wheel with the right features can improve overall system performance.

- 12. Supplier Reputation: The reputation and reliability of the supplier or manufacturer also play a role. Established suppliers with a track record of quality can offer assurance in the performance of their products.

In summary, the choice of ratchet wheels affects the overall performance and reliability of mechanical systems by influencing load capacity, material selection, tooth design, precision, and many other factors. Selecting the right ratchet wheel for a given application is crucial for achieving optimal system performance and longevity.

Can you describe the factors to consider when selecting ratchet wheels for specific applications?

When selecting ratchet wheels for specific applications, several important factors should be taken into consideration to ensure optimal performance and reliability. These factors include:

- 1. Load Capacity: Determine the maximum load or force the ratchet wheel will need to handle. Choose a ratchet wheel with the appropriate load capacity to ensure safe and efficient operation. Larger and more robust ratchet wheels are suitable for heavy-duty applications.

- 2. Space Constraints: Consider the available space within the mechanical system where the ratchet wheel will be installed. Ensure that the selected ratchet wheel size fits within the allocated space without interference or clearance issues.

- 3. Tooth Profile: The tooth profile of the ratchet wheel should match the application’s requirements. Standard ratchet wheels have angled teeth, while fine-tooth ratchet wheels offer finer control. Select the tooth profile that suits the desired level of precision and movement control.

- 4. Material: Choose a ratchet wheel material that is compatible with the application’s environment and demands. Common materials include hardened steel or alloy metals for durability. In corrosive environments, opt for corrosion-resistant coatings or materials.

- 5. Pawl Compatibility: Ensure that the selected ratchet wheel is compatible with the pawl or catch mechanism used in the application. The pawl should effectively engage and disengage with the ratchet wheel’s teeth for reliable operation.

- 6. Precision Requirements: Consider the level of precision required in the application. Fine-tooth ratchet wheels are suitable for applications demanding precise adjustments, while standard ratchet wheels offer a balance of control and strength.

- 7. Operating Conditions: Evaluate the operating conditions, including temperature extremes, humidity, and exposure to chemicals or contaminants. Select ratchet wheels that can withstand these conditions without degradation.

- 8. Customization: For specialized applications or unique requirements, consider the option of custom-designed ratchet wheels. Customization allows for tailoring the ratchet wheel’s size, tooth profile, and material to meet specific needs.

- 9. Maintenance: Assess the ease of maintenance and lubrication requirements. Some ratchet wheels may need periodic cleaning and lubrication to ensure smooth and reliable operation.

- 10. Regulatory Compliance: In some industries, specific standards and regulations may govern the choice of components. Ensure that the selected ratchet wheel complies with relevant industry standards and safety regulations.

By carefully considering these factors, you can select the most suitable ratchet wheel for your specific application, promoting efficient and reliable performance while minimizing the risk of issues or failures.

editor by CX 2024-02-21