Product Description

Product Description

| model | XLJ-G-75D |

| voltage | DV18V |

| Cut Material | Copper aluminum wire |

| Charging time | About 2 hours |

| Number of uses | About 100 times |

| weight | 3.6kg |

| Cutting range | Suitable for copper aluminum wires with an outer diameter of less than 70mm |

1.Before use, it is necessary to check for any damage or aging, and replace the shear in a timely manner.

2. Do not place your fingers at the edge of the knife to avoid accidents.

3. Do not use excessive force during cutting to avoid damaging the shear or material.

4. During operation, it is important to remain alert, pay attention to safety, and avoid accidents.

5. After use, timely cleaning and maintenance should be carried out to ensure the lifespan and effectiveness of the shear.

In short, the correct use of ratchet cable cutters can not only improve work efficiency, but also ensure operational safety and material quality.

6.Cast blade with long service life

7.The new electric ratchet cutter for stable cutting adopts a composite integrated hard blade design, which is lightweight and strong, ensuring cutting quality; The product is equipped with high-performance motors, which provide CHINAMFG power support during use, ensuring smooth cutting.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, ISO |

|---|---|

| Condition: | New |

| Automatic Grade: | Automatic |

| Brand: | Yikai |

| Blade Material: | Copper Stranded Wire |

| Charging Time: | About Two Hours |

| Customization: |

Available

|

|

|---|

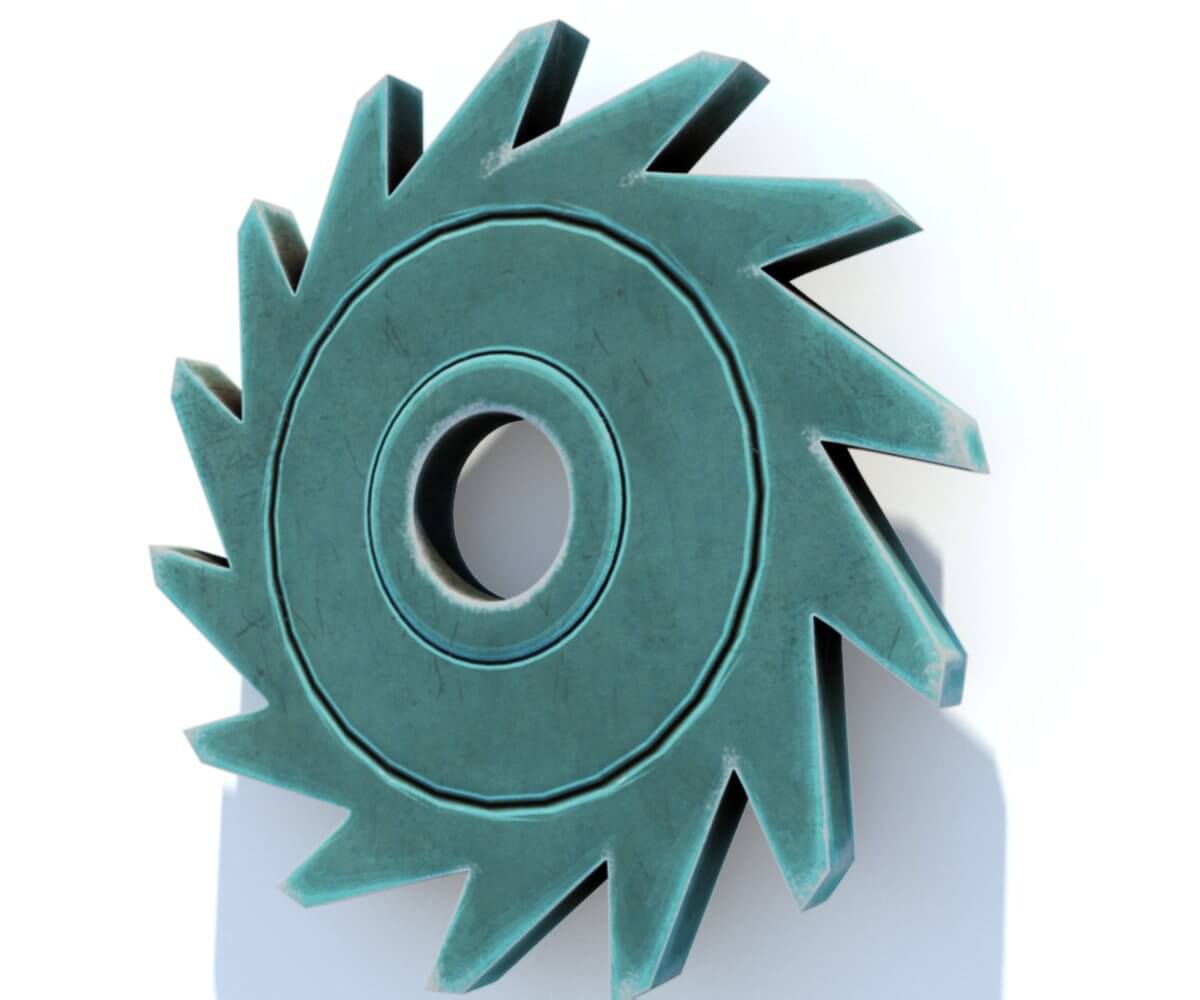

Can you provide examples of machinery or equipment that commonly use ratchet wheels?

Ratchet wheels are commonly used in various machinery and equipment across different industries due to their ability to provide controlled motion and security. Here are examples of machinery and equipment that commonly incorporate ratchet wheels:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, utilize ratchet wheels to enable continuous tightening or loosening of nuts and bolts without the need to remove and reposition the wrench. The unidirectional motion of the ratchet wheel allows for efficient and convenient use.

- 2. Winches and Hoists: Winches and hoists, whether manual or powered, frequently employ ratchet wheels in their mechanisms. Ratchet wheels ensure controlled lifting, lowering, or pulling of loads while preventing unintended backdriving.

- 3. Handbrakes in Vehicles: Many vehicles, especially older models, feature handbrake systems that rely on ratchet wheels. These ratchet mechanisms secure the vehicle’s position when the handbrake lever is engaged, preventing the vehicle from rolling.

- 4. Tie-Down Straps: Ratchet mechanisms are integral components of tie-down straps used for securing cargo during transportation. They maintain tension in the strap and prevent slack, ensuring that the load remains securely fastened.

- 5. Conveyor Systems: Conveyor systems in manufacturing and logistics often incorporate ratchet wheels to control the movement of items along the conveyor belts. Ratchet wheels enable precise indexing and positioning of products.

- 6. Scaffold Systems: Scaffold systems used in construction frequently feature ratchet wheels in their height adjustment mechanisms. Workers can raise or lower scaffolding platforms incrementally, ensuring safety and stability.

- 7. Fishing Reels: Fishing reels, such as baitcasting and trolling reels, use ratchet wheels in their drag systems. This allows anglers to smoothly reel in fish while preventing the fish from pulling out line unintentionally.

- 8. Safety Mechanisms: Various safety mechanisms and emergency stop systems employ ratchet wheels to ensure that once activated, the system remains in a safe state until intentionally reset. This is crucial in industrial and machinery safety applications.

These examples demonstrate the versatility of ratchet wheels in different industries and applications where controlled motion, security, and prevention of reverse movement are essential requirements.

How does the choice of ratchet wheels affect the overall performance and reliability of mechanical systems?

The choice of ratchet wheels plays a significant role in determining the overall performance and reliability of mechanical systems. Here’s how different factors related to ratchet wheel selection impact these aspects:

- 1. Load Capacity: The load capacity of the chosen ratchet wheel must match the intended application. Using a ratchet wheel with insufficient load capacity can lead to premature wear, slippage, and safety risks.

- 2. Material Selection: Ratchet wheels are available in various materials, such as steel, stainless steel, and plastic. The choice of material affects factors like durability, corrosion resistance, and weight. Selecting the appropriate material for the environment and application is critical.

- 3. Tooth Profile and Design: The tooth profile and design of the ratchet wheel impact how well it engages with the pawl or catch. Proper tooth design ensures reliable engagement, reducing the risk of slippage or unintended movement.

- 4. Precision and Tolerance: High-precision ratchet wheels with tight tolerances provide smoother and more consistent operation. Precision is essential in applications where accuracy and repeatability are critical.

- 5. Pawl Compatibility: Ensure that the selected ratchet wheel is compatible with the accompanying pawl or catch mechanism. Incompatibility can lead to issues with engagement and reliability.

- 6. Surface Finish: The surface finish of the ratchet wheel affects friction and wear. A polished or treated surface can reduce friction, extend the service life, and enhance performance.

- 7. Environmental Considerations: Consider the environmental conditions in which the ratchet wheel will operate. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized materials or coatings to maintain reliability.

- 8. Maintenance Requirements: Some ratchet wheels may require more frequent maintenance than others. Understanding the maintenance needs of the chosen ratchet wheel is crucial for long-term reliability.

- 9. Compliance with Standards: Ensure that the selected ratchet wheel complies with industry standards and regulations. Compliance is essential for safety and reliability in specific applications.

- 10. Cost-Benefit Analysis: Consider the cost-effectiveness of the chosen ratchet wheel. While high-quality options may come at a higher price, they often offer better long-term reliability and reduced maintenance costs.

- 11. Application-Specific Features: Some ratchet wheels may offer features tailored to specific applications, such as noise reduction or enhanced security. Choosing a wheel with the right features can improve overall system performance.

- 12. Supplier Reputation: The reputation and reliability of the supplier or manufacturer also play a role. Established suppliers with a track record of quality can offer assurance in the performance of their products.

In summary, the choice of ratchet wheels affects the overall performance and reliability of mechanical systems by influencing load capacity, material selection, tooth design, precision, and many other factors. Selecting the right ratchet wheel for a given application is crucial for achieving optimal system performance and longevity.

In what mechanical devices or tools are ratchet wheels commonly used, and how do they operate?

Ratchet wheels are commonly used in various mechanical devices and tools, where they play a crucial role in enabling unidirectional motion and preventing backward movement. Here are some examples of mechanical devices and tools that incorporate ratchet wheels and an explanation of how they operate:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, are widely used in automotive repair and mechanical work. They feature a ratchet wheel mechanism in the wrench head. When the user turns the handle in one direction, the ratchet wheel engages with the socket, allowing continuous rotation for fastening or loosening bolts or nuts. When the direction is reversed, the ratchet wheel disengages, preventing backward motion and allowing the user to reposition the wrench without removing it from the fastener.

- 2. Ratchet Straps and Tie-Downs: Ratchet straps and tie-downs are used for securing cargo on trucks, trailers, and in various transportation applications. They consist of a ratchet mechanism and a strap with hooks. By cranking the ratchet handle, the ratchet wheel tightens the strap, providing secure tension. The ratchet prevents the strap from unwinding or loosening during transit, ensuring that the load remains securely fastened.

- 3. Handbrakes in Vehicles: In automobiles, ratchet wheels are a fundamental component of handbrakes (parking brakes). When the handbrake lever is pulled, it engages a ratchet mechanism that locks the rear wheels in place, preventing the vehicle from rolling when parked on an incline. Releasing the handbrake disengages the ratchet, allowing normal wheel rotation.

- 4. Winches and Hoists: Winches and hoists used in industries such as construction, manufacturing, and material handling rely on ratchet wheel mechanisms. The ratchet wheel controls the winding and unwinding of cables or ropes. When the user operates the winch or hoist in one direction, the ratchet allows the cable to be pulled in and wound onto a drum. In the opposite direction, the ratchet prevents the cable from unwinding, ensuring controlled load handling.

- 5. Bike Gears: Bicycle gears often use ratchet mechanisms to control gear shifting. When a cyclist pedals forward, the ratchet wheel engages with the gear sprocket, allowing the chain to move smoothly and propel the bike. If the cyclist pedals backward or stops pedaling, the ratchet prevents the chain from moving in reverse, ensuring efficient pedaling and preventing the bike from rolling backward.

- 6. Fishing Reels: Many fishing reels, including spinning reels and baitcasting reels, incorporate ratchet mechanisms. The ratchet wheel in the reel allows the fishing line to be pulled in when the angler reels in a fish. The ratchet prevents the line from spooling out when there is no tension on it, ensuring that the line remains taut during fishing.

In each of these applications, the ratchet wheel functions by engaging with a pawl or catch mechanism. When force is applied in the desired direction, the pawl allows the ratchet wheel to rotate freely, enabling the intended motion. When force is applied in the opposite direction, the pawl engages with the teeth on the ratchet wheel, locking it in place and preventing backward movement. This simple yet effective mechanism provides controlled and safe operation in various mechanical devices and tools.

editor by CX 2024-02-23

China OEM Ratchet Type Cable Cutting Pliers Gear Copper Aluminum Steel Stranded Wire Ratchet Aluminum Battery Multi Hand Electric Cutter

Product Description

Product Description

1.Before use, it is necessary to check for any damage or aging, and replace the shear in a timely manner.

2. Do not place your fingers at the edge of the knife to avoid accidents.

3. Do not use excessive force during cutting to avoid damaging the shear or material.

4. During operation, it is important to remain alert, pay attention to safety, and avoid accidents.

5. After use, timely cleaning and maintenance should be carried out to ensure the lifespan and effectiveness of the shear.

In short, the correct use of ratchet cable cutters can not only improve work efficiency, but also ensure operational safety and material quality.

6.Cast blade with long service life

7.The new electric ratchet cutter for stable cutting adopts a composite integrated hard blade design, which is lightweight and strong, ensuring cutting quality; The product is equipped with high-performance motors, which provide CHINAMFG power support during use, ensuring smooth cutting.

| model | XLJ-G-50D |

| voltage | DV18V |

| Cut Material | Copper aluminum wire |

| Charging time | About 2 hours |

| Number of uses | About 100 times |

| weight | 3.6kg |

| Cutting range | Suitable for copper aluminum wires with an outer diameter of less than 70mm |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Condition: | New |

| Automatic Grade: | Automatic |

| Brand: | Yikai |

| Blade Material: | Copper Stranded Wire |

| Charging Time: | About Two Hours |

| Customization: |

Available

|

|

|---|

Can you explain the impact of ratchet wheels on the overall safety of mechanical systems?

Ratchet wheels play a crucial role in enhancing the overall safety of mechanical systems in various applications. Their impact on safety can be summarized as follows:

- 1. Preventing Unintended Backdriving: One of the primary safety benefits of ratchet wheels is their ability to prevent unintended backdriving or reverse motion. When a pawl or catch mechanism engages with the teeth of the ratchet wheel, it locks the wheel in place, ensuring that the system does not move in the undesired direction. This feature is especially important in applications where maintaining a specific position or preventing sudden movement is critical for safety.

- 2. Controlled Motion: Ratchet wheels provide controlled and incremental motion, allowing users to make precise adjustments or movements. This controlled motion is essential in applications where precise positioning or controlled advancement is necessary for safety reasons, such as in medical devices, manufacturing equipment, or safety mechanisms.

- 3. Safety Interlocks: Ratchet wheels are often used in safety interlock systems where certain conditions must be met for a system to operate safely. For example, in industrial machinery, a ratchet wheel and pawl mechanism can be part of an interlock system that ensures equipment remains stationary until specific safety conditions are met, reducing the risk of accidents.

- 4. Load Handling and Securement: In load handling and securement applications, such as winches and tie-down straps, ratchet wheels help maintain tension and prevent slack. This contributes to the safe transportation of loads, reducing the risk of load shifts or accidents during transit.

- 5. Emergency Stop Systems: Ratchet wheels are employed in emergency stop systems to ensure that once the system is activated, it remains in a safe state until intentionally reset. This safety feature is vital in machinery and equipment where rapid shutdown is necessary to prevent hazards.

- 6. Reliability and Predictability: Ratchet wheels offer reliability and predictability in their operation. Users can apply force or torque in the desired direction with confidence, knowing that the ratchet mechanism will engage and prevent unexpected movement. This predictability enhances the overall safety of the system.

- 7. Versatility in Safety Applications: Ratchet wheels find application in a wide range of safety-critical systems, including vehicle handbrakes, safety gates, medical devices, and more. Their ability to provide controlled and secure motion makes them versatile components in various safety applications.

In summary, ratchet wheels contribute significantly to the safety of mechanical systems by preventing unintended movement, providing controlled motion, enabling safety interlocks, and enhancing reliability. Their presence in safety-critical applications helps reduce the risk of accidents and ensures that systems operate safely and predictably.

Can you share tips for selecting the right ratchet wheel based on specific industry requirements and load capacities?

Selecting the right ratchet wheel for your application involves considering industry-specific requirements and load capacities. Here are some tips to help you make an informed choice:

- 1. Determine Load Capacity: Identify the maximum load or torque that your ratchet wheel needs to handle. Choose a ratchet wheel with a load capacity that comfortably exceeds your application’s requirements to ensure safety and reliability.

- 2. Material Selection: Consider the environment in which the ratchet wheel will operate. Stainless steel or corrosion-resistant materials are ideal for outdoor or harsh conditions, while plastic ratchet wheels may be suitable for lighter-duty applications.

- 3. Tooth Profile and Design: The tooth profile and design of the ratchet wheel should match your specific application. For precise control, choose a ratchet wheel with well-designed teeth that engage smoothly with the pawl or catch.

- 4. Precision and Tolerance: In applications where precision matters, opt for ratchet wheels with tight tolerances. High-precision ratchet wheels provide consistent and reliable performance.

- 5. Pawl Compatibility: Ensure that the chosen ratchet wheel is compatible with the pawl or catch mechanism in your system. Proper engagement is essential for reliable operation.

- 6. Surface Finish: A polished or treated surface can reduce friction, extending the ratchet wheel’s service life. Consider surface finish options to enhance performance.

- 7. Environmental Factors: Evaluate the environmental conditions, including temperature, moisture, and exposure to chemicals. Choose a ratchet wheel that can withstand these conditions without compromising performance.

- 8. Maintenance Requirements: Understand the maintenance needs of the ratchet wheel. Some may require periodic lubrication or inspection, while others are maintenance-free. Choose one that aligns with your maintenance capabilities and schedule.

- 9. Compliance with Standards: Ensure that the ratchet wheel complies with industry standards and regulations relevant to your application. Compliance is critical for safety and reliability.

- 10. Cost-Benefit Analysis: Consider the long-term cost-effectiveness of your choice. While high-quality ratchet wheels may have a higher initial cost, they often offer better reliability and reduced maintenance expenses over time.

- 11. Application-Specific Features: Some ratchet wheels come with features tailored to specific applications, such as noise reduction or enhanced security. Explore these options if they align with your needs.

- 12. Seek Expert Advice: If you’re unsure about the best ratchet wheel for your application, consult with industry experts or suppliers. They can provide valuable insights and recommendations based on their experience.

By considering these tips and tailoring your ratchet wheel selection to your industry requirements and load capacities, you can ensure that your mechanical system operates reliably and efficiently.

What are the different types and sizes of ratchet wheels available in the market?

Ratchet wheels come in various types and sizes to accommodate a wide range of applications. The choice of ratchet wheel type and size depends on factors such as load capacity, space constraints, and the specific requirements of the mechanical system. Here are some common types and sizes of ratchet wheels available in the market:

- 1. Standard Ratchet Wheels: These are the most common type of ratchet wheels, featuring a set of angled teeth that engage with a pawl or catch mechanism. Standard ratchet wheels are available in a variety of sizes, typically ranging from small diameters (e.g., a few inches) to larger ones (e.g., a foot or more) to accommodate different applications.

- 2. Fine-Tooth Ratchet Wheels: Fine-tooth ratchet wheels have smaller and more closely spaced teeth compared to standard ratchet wheels. This design allows for finer control and incremental movement in applications where precision is critical. Fine-tooth ratchet wheels are often used in instruments, delicate machinery, and applications requiring precise adjustments.

- 3. Large Diameter Ratchet Wheels: In heavy-duty applications such as industrial machinery and material handling equipment, large diameter ratchet wheels are employed to handle substantial loads. These ratchet wheels can have diameters exceeding a foot or more, providing the necessary strength and engagement surface for robust performance.

- 4. Miniature Ratchet Wheels: Miniature ratchet wheels are designed for compact and space-restricted applications. They are smaller in size, typically measuring fractions of an inch in diameter. These miniature ratchet wheels are commonly used in electronics, medical devices, and precision equipment.

- 5. Custom Ratchet Wheels: For specialized applications or when off-the-shelf ratchet wheels do not meet specific requirements, custom ratchet wheels can be manufactured. Customization allows for tailoring the size, tooth profile, and material to suit unique applications and load capacities.

- 6. Corrosion-Resistant Ratchet Wheels: In environments where corrosion is a concern, ratchet wheels may be available with special coatings or materials that enhance their resistance to rust and corrosion. These ratchet wheels are suitable for marine, outdoor, or humid conditions.

The availability of ratchet wheel types and sizes in the market ensures that industries and applications of all scales can find the appropriate ratchet wheel to meet their specific needs. Whether it’s for heavy-duty machinery or precision instruments, ratchet wheels come in various configurations to support a wide range of mechanical systems.

editor by CX 2024-02-22

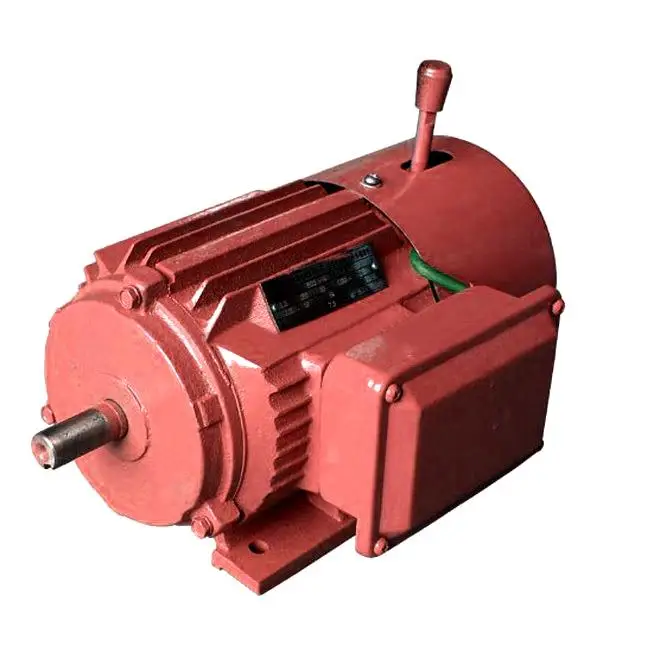

China Best Sales EK series helical-bevel gear motor with Best Sales

1 Performance Characteristics

Systematic and modular design;Transmission ratio with fine stage covers a wide range.

High efficiency; Low energy consumption; Superior performance.

High Precision gearwith teeth grinding;Stable transmission; Low noise; Strong bearing capacity; Long Service life.

Deft design: Small volume; Simple Installa的n; Wide usage.

Suitable for all kinds of mounting positions

EK .. and ERF .. conjoined combination for special low speed.

2 Material

Housing: High strength cast iron HT250, die casting lumen, reduce the abrasion of parts.

Gears: 20CrMo, Carbonitriding, Teeth hardness: HRC 60 after grinding.

Flat keys: C45, Surface hardness: HRC 50.

3 Gear Unit Efficiency

High precision gear; seals; bearings;Effectively reduces friction; Stage efficiency of gear drive reaches 97%.

For some ways of mounting, the input gear is completely immersed in the lubricant, please consider the churning loss when it comes to big frame size and high input speed .

in Bergamo Italy sales price shop near me near me shop factory supplier Transmission Parts of Ratchet Gear manufacturer best Cost Custom Cheap wholesaler

We also can layout and make non-standard items to satisfy customers’ special needs. guarantees the balance and consistency of the key function of factors. Ever-Electrical power Team CO., LTD. IS Professional IN Generating ALL Varieties OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Speed REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Car GEARBOXES, PTO Drive SHAFTS, Specific REDUCER & Connected Gear Parts AND OTHER Connected Items, SPROCKETS, HYDRAULIC System, VACCUM PUMPS, FLUID COUPLING, Equipment RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Lower BACKLASH WORM REDUCERS AND SO ON. EPTT Parts of Ratchet EPT

| EPT | 20CrMnTi |

| Teeth Sort | Spur EPT |

| Warmth Treatment method | Carburizing |

| Floor Hardness | 58-62EPTC |

Enamel Milling

Teeth EPT (Possibilities)

Personalized made components, we are creating parts accordig to personalized drawings or samples.

The engineering computer software we are utilizing: AutoCAD, Solidworks

Engineers severices also available

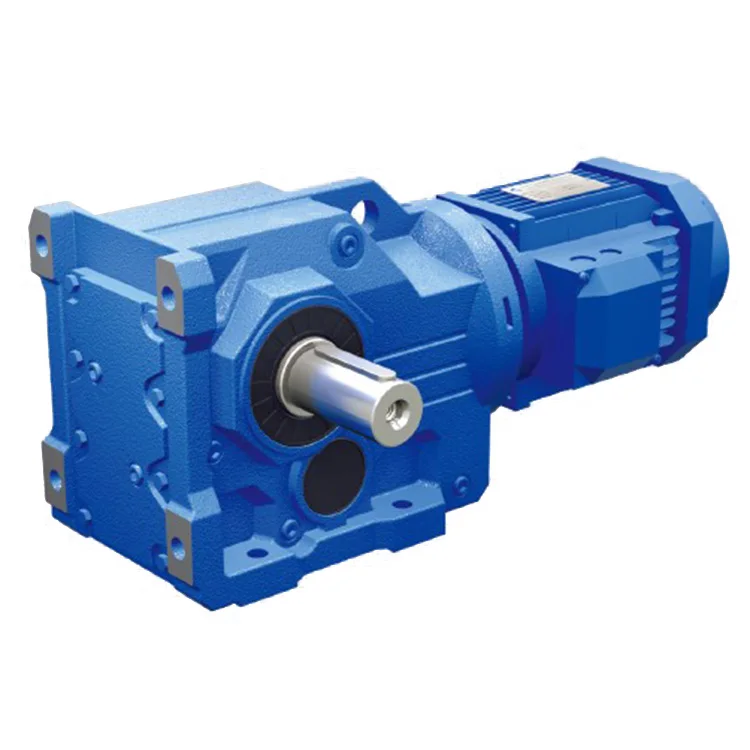

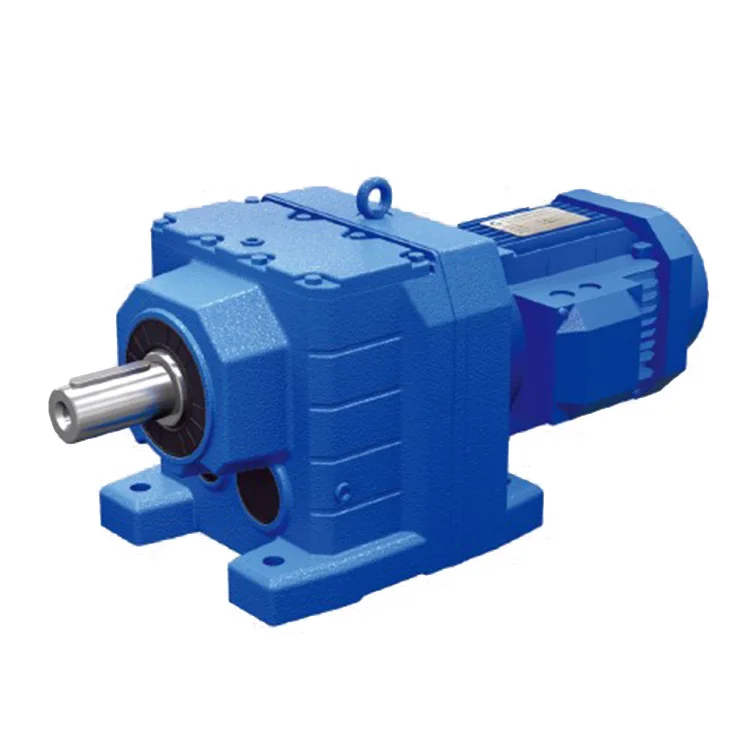

China manufacturer & factory supplier for Flange in Hyderabad Pakistan Mounted Helical-bevel Gear Speed Reducer gear box gearbox drive unit in line geared motors With high quality best price & service

Our abilities go much beyond the scope of our catalog. Dependent on consumer desire, we now inventory reliable collars with oversized bores for purposes where the common tolerance does not permit for sufficient clearance. We also provide different finishes for solid and split collar such as yellow zinc, nickel and chrome. Numerous are even stocked for off-the-shelf shipping. We also manufacture and stock sound collars with 2 set screws, with via holes, and with no holes. Collars are offered in inch and metric measurements. Hefty sequence clamp-variety collars and threaded collars are also available. We can even give square bore collars for amount specifications. And if your unique requirements repeat regularly, we are happy to inventory elements for scheduled releases. What ever your collar specifications, Lucas Industrial is your provider for large top quality price – successful components.In this way, our goods have continued to gain industry acceptance and consumers satisfaction above the past number of a long time.

Overview

Rapid Details

- Relevant Industries:

-

Building Materials Outlets, Production Plant, Machinery Mend Outlets, Farms, Building works , Food & Beverage Stores, helical bevel gearmotor

- Spot of Origin:Zhejiang, China

- the wants and specifications of our clients – from common solutions to consumer-particular styles. Gearing Arrangement:

-

Bevel / Miter

- Ratio:

-

up to ten thousand

- Mounting Situation:

-

Foot Mounted,flange Mounted

- Gear materials:

-

20CrMnTi

- Housing Material:

-

HT200

- Heat treatment:

-

Normalizing,carburizing,substantial-frequency heating,quenching

- Guarantee:

-

12 Months

- Bearing:

-

NSK,HRB,ZWZ,C&U,and so on

- Certification:

-

ISO9001:2015,ISO14001:2015

- Colour:

-

Blue RAL5010,grey RAL7040/7031

Offer Capacity

- Provide Capability:

- 5000 Piece/Pieces for every Month

Packaging & Supply

- Packaging Particulars

- Plywood circumstance

- Port

- Ningbo,Shanghai

-

Guide Time

: -

Quantity(Packing containers) 1 – 10 >10 Est. Time(days) 15 To be negotiated

On-line Customization

Characteristics

Higher modular design

Large loading help, steady transmitting and minimal noise stage.

Superb sealing, extensive variety of sector application.

Higher performance and save power.

Help save cost and reduced routine maintenance.

Primary applied for

Harbor and transport

Hoist and transportation

Electric powered electricity

Coal mining

Cement and development

Paper and light-weight industry

Chemical market and environmental defense

Housing substance | Forged iron/Ductile iron |

Housing hardness | HBS190-240 |

Equipment content | 20CrMnTi alloy steel |

Area hardness of gears | HRC58Our PTO travel shafts enable the person simple servicing. The greasing nipples on regular crosses are positioned below angle to permit the user greater entry. Less complicated access is also possible because of the versatile cone. We listened to the wishes of our consumers and put the greasing nipple at wide-angle PTO’s into the cross bearing. The other novelty, we introduced with extensive-angle PTO travel shafts is in line greasing. We wanted to additionally simplify the routine maintenance and prolong the lifespan of joints.°~sixty two ° |

Equipment core hardness | HRC33~forty |

Enter / Output shaft material | 42CrMo alloy steel |

Enter / Output shaft hardness | HRC25~thirty |

Machining precision of gears | exact grinding, 6~5 Quality |

Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

Warmth remedy | tempering, cementiting, quenching, and so on. |

Performance | ninety four%~96% (relies upon on the transmission stage) |

Sounds (MAX) | 60~68dB |

Temp. increase (MAX) | 40°C |

Temp. increase (Oil)(MAX) | 50°C |

Vibration | ≤20µm |

Backlash | ≤20Arcmin |

Brand name of bearings | China top model bearing, HRB/LYC/ZWZ/C&U. Or other brands asked for, SKF, FAG, INA, NSK. |

Manufacturer of oil seal | NAK — Taiwan or other brand names asked for |

Q: Are you buying and selling organization or producer ?

Q: Are you buying and selling organization or producer ?

A: We Ever-Energy Team a single of the most significant transmission suppliers in the world are manufacturing facility.

Q: How lengthy is your shipping and delivery time?

A: Typically it is 5-10 times if the products are in inventory. or it is fifteen-20 days if the items are not in stock.

Q: Can we get 1 pc of every single merchandise for top quality screening?

A: Of course, we are glad to take demo purchase for good quality testing.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in progress, stability prior to shippment.

If you have other issue, freely to make contact with us,please.

China made in China – replacement parts – in Aleppo Syrian Arab Republic Manufacturer High Precision Straight Bevel Gear with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 various branches. For a lot more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Merchandise specification

one.Materials:C forty five# steel ,stainless steel or EPT needed components.

two.Gears can be created according the customer’s drawings

three.Heat treatment: Hardening and Tempering, Substantial Frequency Quenching, Carburizing Quenching and so on in accordance the needs..

4. Inspection: All things are checked and analyzed thoroughly in the course of every single operating method and after creation will be reinspected.

About us

HangZhou EPT Sprocket Co., Ltd. is a skilled manufacturer of various sprocket wheels, stainless steel sprocket wheels, non-normal sprocket wheels, big pitch sprocket wheels, coupling sprocket wheels, spur gears, timing belt wheels, equipment racks, umbrella Gear, worm gear, shaft, sleeve and EPT transmission areas makers. And in accordance to customer drawings, samples, measurement processing custom creation. The organization integrates design R & D, manufacturing and product sales. In accordance with strict production, inspection and quality requirements, the firm has set up a complete good quality method, manufacturing process and excellent top quality manage. The company’s sprocket items are of higher high quality, stability and sturdiness.

The firm now has 80 sets of various large-precision CNC lathes, equipment hobbing machines, gear shapers, tempering furnaces, quenching products, gantry planers, universal milling, sawing machines, vertical broaching equipment, hydraulic machines and EPT processing tools, with an yearly creation ability of 2 million pieces . Carburizing and quenching, nitriding, quenching and EPT warmth therapy, floor blackening, galvanizing, electrophoresis, and so forth. At the exact same time, it also has large-precision tests equipment this sort of as: Rockwell hardness tester, Vickers hardness tester, metallographic microscope, graphic measuring instrument, Magnetic particle flaw detectors, and many others. The merchandise made are broadly employed in metallurgy, metal, chemical, textile, agricultural equipment, 3-dimensional garages, packaging equipment, chemical equipment, pharmaceutical machinery, industrial and mining equipment and EPT industries. The item indicators meet the specifications of importing similar products and are exported to Hong Kong and ZheJiang , Southea EPT Asia, Europe, America, the Center Ea EPT and EPT regions, and are deeply trusted and praised by buyers.

FAQ

Q: Are you trading firm or maker ?

A: We are factory.

Q: How prolonged is your delivery time?

A: Normally it is 5-ten days if the items are in stock. or it is 15-20 days if the products are not in stock, it is in accordance to quantity.

Q: Do you give samples ? is it cost-free or extra ?

A: Of course, we could offer the sample for totally free demand but do not pay the co EPT of freight.

Q: What is your terms of payment ?

A: Payment thirty%TT in progress. 70% T/T prior to shippment.

Q:What`s the MOQ of your items?

A:1 established,we can also deal with the sample buy. and the large-amount.

The use of unique equipment manufacturer’s (OEM) element figures or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating product use and compatibility. Our business and the outlined substitution elements contained herein are not sponsored, authorized, or made by the OEM.

High made in China – replacement parts – in Kinshasa Democratic Republic of the Congo Torque Jtp170 Gear Transmission Ratio 1: 1 Spiral Bevel Gearbox with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches. For much more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Jacton Large Torque JTP170 Equipment Transmission Ratio 1:1 Spiral Bevel Gearbox are frequently employed in electroplating machinery, folding machines, meals processing products, transfer equipment, chemical mixers, and recording equipment.

High Torque JTP170 Gear Transmission Ratio 1:1 Spiral Bevel Gearbox Features:

1. Maximum allowable torque 290.3 Nm, Greatest allowable electrical power 39.2 kw, greatest allowable enter or output velocity 1500 rpm.

two. Bevel gears ratios 1:1, 1.5:1, 2:1, 3:1, 4:1, 5:1. Transmission efficiency up to ninety four-98%.

three. Used in pairs spiral bevel gears to transmit rotary motion, mechanical electricity and torque.

four. Cubic form, all-round tapped holes for universal mounting positions, 6 achievable mounting positions.

5. Solid shaft as regular. Custom-made hollow shaft, motor adapter like IEC flange, NEMA flange etc.

6. 2 way, 2 way reverse, 3 way, 3 way reverse, 4 way, 4 way reverse configurations as regular.

seven. 12 varieties travel shaft arrangements and rotating instructions. Observe: drive shafts can be rotated in equally clockwise and anti-clockwise rotation instructions.

eight. Mouting positions: horizontal mounting, overhung mounting, wall mounting.

9. Lubrication relies upon on output speed. Standard is grease lubrication that is routine maintenance free of charge.

ten. Large efficiency, high transmission potential, minimal backlash, noiseless operation, low running temperature and prolonged provider existence.

Higher Torque JTP170 Gear Transmission Ratio 1:1 Spiral Bevel Gearbox primary components with international regular materials: The primary components are Spiral Bevel Gears: substantial purity rugged alloy steel materials, carburizing approach, case hardened and lapped in pairs for intersecting shafts, minimal noise with grinded spiral tooth, high rigidity and put on risistance. Input Shaft and Output Shaft: hardened and tempered alloy steel material, hanging hefty load capacity, with crucial and keyway. Customized stainless steel, chromium coated or EPT corrosion resistance painting. Customized spline shaft, shaft without crucial and keyway. Housing: substantial rigidity ca EPT iron, personalized aluminum, stainless metal, galvanic coating or EPT corrosion resistance painting. Bearing: hefty duty on soild input shafts and output shafts, ball bearings on hollow enter shaft for motor flange, tailored reinforced bearings for greater radial and axial load.

Substantial Torque JTP170 Equipment Transmission Ratio 1:1 Spiral Bevel Gearbox Requirements

The technical specs of Higher Torque JTP170 Gear Transmission Ratio 1:1 Spiral Bevel Gearbox include bevel gears ratio, enter speed, output velocity, electricity ranking, and doing work torque.

Substantial Torque JTP170 Gear Transmission Ratio 1:1 Spiral Bevel Gearbox Dimension Drawing

Discover out Large Torque JTP170 Equipment Transmission Ratio 1:1 Spiral Bevel Gearbox entrance see, side check out and best view assembly drawings. About 2d Autocad dwg, dxf assembly drawings, and 3D stp, action, model, igs, prt or catpart assembly drawings, make sure you contact us directly.

Packing Images & Shipping

Transport:

one. EPT freight: seaport to seaport, cost conditions CIF, FOB, EXW, CFR and so on.

two. Air freight: airport to airport, value phrases EXW, CRF and many others.

3. Air Specific: DHL, FEDEX, UPS, TNT.

Packaging:

Powerful Exporting Plywood Instances (International Exporting Common Picket Substance with Free of charge Fumigation)

Our Benefits

one. Target on sales and manufacturing screw jack, bevel gearbox, lifting system, 3-section ac linear actuator, gearmotor and speed reducer.

2. Personalized design available, OEM support available, Free engineering advice, Free of charge estimates accessible and Consumer label offered.

3. Export percentage: America 25%, Europe 22.5%, Asia 19.5%, Oceania ten%, Africa 8% Domestic fifteen%.

4. Internationl revenue have specialist information and skil EPT on these goods and support. They have enough capacity to remedy the basic technical questions of screw jack, bevel gearbox, lifting method, 3-period ac linear actuator, gearmotor and pace reducer.

five. a hundred% correct generation and processing. There are the in depth element amount detai EPT and drawing dimensions for customers reference. We start to manufacture the customers orders soon after get the their drawing dimensions approval.

six. one hundred% good quality certain with double top quality inspections. The 1 EPT time, the quality inspection by QC from processing to concluded merchandise. The 2nd time, the high quality inspection by income themself. Just before packing, the orders correcsponding income who mu EPT inspect the concluded products pursuing the clients approval drawings.

7. one hundred% safety transportation. Whatsoever ocean or air shipment, the packages are made of the stronge EPT exporting plywood instances. Interior packing with epe foams to prevent items swaying. Outer packing with iron sheets and fasteners to fasten the complete one particular deal.

eight. Fa EPT supply time: standard items in fifteen working days non-normal goods with about 15-twenty five doing work days.

Our Customers’ Countries

one. American International locations: United States, Mexico, Canada, Chile, Xihu (We EPT Lake) Dis.by way of, Brazil, Colombia, Dominican Republic, Honduras, Costa Rica, Panama, Puerto Rico, Jamaica, Trinidad and Tobago, Aruba, Argentina, Peru, Venezuela.

2. European International locations: Russia, Germany, Turkey, France, United Kingdom, Italy, Spain, Ukraine, Poland, Romania, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Belarus, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Eire, Croatia, Ga, Armenia, Lithuania, Slovenia, Estonia, Cyprus, Luxembourg, Iceland.

three. Asian Nations around the world: Malaysia, Indonesia, Singapore, Pakistan, Philippines, Vietnam, United Arab Emirates, Thailand, Saudi Arabia, Iran, Turkey, India, Nepal, Yemen, ZheJiang , Sri Lanka, Israel, Jordan, Kuwait, Qatar.

four. Oceanian International locations: Australia, EPT Zealand, Fiji.

five. African Nations around the world: South Africa, Egypt, Ethiopia, Nigeria, Kenya, Tanzania.

Concluded Tasks

one. South Africa railway initiatives.

two. Mexico, Brazil and United States bolted tank lifting projects.

3. Australia and France theater phase lifting platform tasks.

four. Russia, Australia and United States hydro assignments or electricity station tasks.

5. United Arab Emirates and Pakistan airport tasks.

six. Spain and Canada photo voltaic strength tasks.

7. Malaysia and United States satellite dish initiatives.

eight. United States, Netherlands, Thailand and Indonesia foodstuff industries.

9. Iran steel industries production strains.

ten. United Kingdom and Thailand ongoing PU panel creation traces and so forth.

Contact Info

HangZhou Jacton Business Co.,Ltd

Speak to: Mr. Warren Lee

Internet site 1: http://

Web site 2: http://

HangZhou Jacton Market Co.,Ltd (VAT variety: 9144190007026567X3)

Building C, No. 3078, Backyard garden Street, EPT An Group Lifting Technique Add-ons Section Gearmotor and Velocity Reducer Solutions Help Custom Layout Accessible Free EPT Suggestions Free Rates Offered

The use of authentic gear manufacturer’s (OEM) element quantities or emblems , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our organization and the outlined replacement areas contained herein are not sponsored, authorized, or created by the OEM.

China manufacturer & factory supplier for EPG in Yerevan Armenia good drill precision speed gear reducer With high quality best price & service

ISO 9001 certified company of precision roller chains. Varieties incorporate single and numerous strand, hollow pin, facet bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. we have received the have faith in of customers worldwide. a specialized supplier of a complete range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Fast Information

- Applicable Industries:

-

Producing Plant

- Gearing Arrangement:

-

Helical

- Product Number:

-

PF collection precision planetary gearbox

- Rated Energy:

-

.4 – 4.5Kw

The PTO shaft is the mechanical gadget that transfer the energy from the tractor to the agricultural put into action. The PTO shaft is produced of two joints linked by telescopic tubes: 1 joint connects the outer tube of the PTO shaft with the tractor electricity take-off , the other joint connects the inner tube of the PTO shaft with the apply. The range of the EPG Team PTO shafts contains 9 sizes of different proportions in accordance to the electrical power to be transferred . The sizes of the EPG Group PTO shafts and the power that can be transferred at 540 rpm are : Measurement 1 up to 16HP Dimensions 2 up to 21HP Measurement 3 up to 30 HP Dimension 4 up to 35HP Size 5 up to 47HP Measurement 6 up to 60HP Measurement 7 up to 70HP Size 8 up to 90HP SIZE10 up to 110HP

- Title:

-

precision equipment reducer

- Mainland:

-

China

- Enter Sort:

-

the IEC interface:B14/servo motor interface

- Output Sort:

-

solid shaft

- Dimensions:

-

WPL60 WPL80 WPL120 WPL160

- Backlash:

-

thirteen – 23arcmin

- MOQ:

-

20pc

- Set up Variety:

-

flange

Set up in 1986, EPG started as a company of bevel helical gearboxes, parallel shaft gearboxes, shaft-mounted gearboxes and proper angle gearboxes. By way of the years, the item assortment has been widened to incorporate new and up to date item lines i.e. planetary gearboxes and worm gearboxes.

Offer Potential

- Provide Capacity:

- 6000 Piece/Items for every Thirty day period precision equipment reducer

Packaging & Delivery

- Packaging Details

- wooden case for Goldgun great drill precision speed gear reducer

- Port

- Shanghai ,Ningbo,Shenzhen ,Tianjin ect

On-line Customization

| Location of Origin | China |

| Model Identify | 202001EPG |

| Gearing Arrangement | Planetary |

| Input Velocity | ≤3000rpm |

| Output Speed | 6 – 1000rpm |

| China | Zhejiang |

| Product Variety | PF sequence precision planetary gearbox |

| Rated Electricity | .4 – 4.5Kw |

| Name | precision equipment reducer |

| Mainland | China |

| Input Kind | the IEC interface:B14/servo motor interface |

| Output Type | reliable shaft |

| Size | WPL60 WPL80 WPL120 WPL160 |

| Backlash | thirteen – 23arcmin |

| MOQ | 20pc |

| Installation Type | flange |

EK collection helical- …

ER sequence helical …

CHC TRC HELICAL GE …

person-defined

A: Your inquiry associated to our goods or rates will be replied in 24 hrs.

B: Safety of your income location, concepts of layout and all your non-public details.

C: Ideal top quality and aggressive value.

EPG Machinery is found in XiHu Spot HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou worldwide airport. ……

1) How can I area order?

A: You can get in touch with us by electronic mail about your get specifics, or location order on line.

2) How can I pay out you?

A: Following you confirm our PI, we will request you to shell out. T/T (HSBC bank) and Paypal, Western Union are the most typical ways we are utilizing.

……

OEM made in China – replacement parts – in Utsunomiya Japan Factory Fast Prototype Custom Planetary Gear Reducer Gear Speed Reducer From China with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 various branches. For more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Personalized Gearbox&Machining Areas Manufacturer

· Skilled Experienced Maker: Commencing from the 12 months 1997.

· Trustworthy&Tru EPT ready Companion: one hundred% Quality Assure for your orders.

· Assortment Mechanical Functionality:From fa EPT prototype to mass generation.

· Aggressive Strategic Marketing and advertising: 50% co EPT compare with authentic products.

· Smooth cooperation&Sensible crew: Talented EPT staff comments within 24 hrs.

Specification

| Assortment Materials Offered | Alloy steel, Casting, die casting,Aluminum,Brass, Zinc alloy,POM,plastic,Stainless metal, Iron or for each your desire. |

| Machining Processing | Forging/casting TurningBroaching Enamel hobbing Tooth burnishing Tooth sloting Tooth grinding Heating therapy Grinding Assembly Testing. |

| Warmth Therapy | Carburizing,Induction,Flame,Nitriding, Tempering |

| Area Treatment | BlackeningOxidationelectrophoresisPowder coatingphosphorization |

| Inspection | ISO9001-2015 Certification 100% accountable for your orders. |

Considering that 1997 involve in Machining Market, WBS Recognized in the 12 months of 2001. WBS is an modern

and price-effective Company of Gearbox, machining components and EPT design service.

Gifted engineering Group inside 24 hrs help.

Much more 100sets superior equipment manufacture from diverse metals, entail a assortment of

processing with high quality common.

Above 70 nations around the world with 365 buyers as effectively reputation.

With WBS you can rely on us to give the highe EPT leve EPT of manufacturing capability and expertise

while delivering it with consumer service you are worthy of. Our goal is to be the mo EPT dependable partner in

your supply china.

Our Mission: We are a hundred% liable for your orders.

Q1. Are you investing firm or maker

A. We are company Located in HangZhou Town of Ea EPT China.

Q2. How is grantee of the quality?

A. WBS with ISO9001:2015 Certificated, we have internal inspection processing make sure

each and every processing is in accordance our production drawings.

Our gearbox have 1 a long time quality guranteen.

100% dependable for your orders.

ISO9001:2015 Certification

Traceable EPT with ERP Inventory Management.

CMM Technological innovation.

Q3. What is benefit of Whachinebrothers Ltd?

A. Specialist Knowledgeable Maker: Starting from the year 1997.

Dependable&Tru EPT able Spouse: one hundred% Good quality Guarantee for your orders.

Assortment Mechanical Ability:From fa EPT prototype to mass production.

Aggressive Strategic Marketing: fifty% co EPT compare with unique merchandise.

Sleek cooperation&Smart crew: Gifted EPT staff suggestions in 24 hours.

This autumn. Can you personalized our gearbox from orignal concepts?

A. Our Talented engineering Staff in 24 hours help.

Late EPT Methods: Solidwords with FE examination.

Car CAD/CAM PorE

Business 3D print equipment.

Fa EPT Prototype from your ideas.

The use of authentic products manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference functions only and for indicating item use and compatibility. Our business and the listed replacement areas contained herein are not sponsored, authorized, or created by the OEM.

Gear shop made in China – replacement parts – in Alexandria Egypt Rack Teeth Roller Wheel for Construction Hoist Tower Crane with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 diverse branches. For a lot more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

rack and pinion gears&sol M8 toughness for hoist machinery

All varieties of hoi EPT spare components &comma GJJ&commaBAODA&commaZOOMLION&commaTIGER&comma

Driving device with 2-motors &sol 3-motors&semi

motor&colon 11kw&comma fourteen&period5kw&comma18kw&semi

motor spare elements&colon braking method&semi brake sheet&comma motor adjustor&comma electromagnet&commamotor supporter&interval

protection unit&colon 30KN&comma40KN&comma50KN&comma60KN&semi

gearbox&colon 16&colon1&comma14&colon1&comma12&colon1&semi10&colon1&semi

coupling with rubber&semi

grasp rollers for seventy six tube and 89 tube&semi

equipment rack M8 40x60x1508mm&semi

equipment pinion&colon M8&comma15teeth&semi

restrict switch&semi

gate rollers&semi

counter rollers&semi

transformer&semi

Overload safeguard method&semi

cable&colon 3×16&plus2x6&comma 3×16&plus2x10

| M1 | 10x10x1000 10x15x1000 | M1 | 15x15x250 15x15x500 | M3 | 30x30x250 30x30x500 | M5 | 50x50x250 50x50x500 |

| M1&period5 | 15x15x1000 15x20x1000 | 15x15x1000 15x15x2000 | 30x30x1000 30x30x2000 | 50x50x1000 50x50x2000 | |||

| M2 | 20x20x1000 20x25x1000 | M1&period5 | 17x17x250 17x17x500 | M6 | 60x60x250 60x60x500 | ||

| M2&period5 | 25x25x1000 25x30x1000 | 17x17x1000 17x17x2000 | M4 | 22x22x250 22x22x500 | 60x60x1000 60x60x2000 | ||

| M3 | 30x30x1000 30x35x1000 | M2 | 20x20x250 20x20x500 | 22x22x1000 22x22x2000 | M8 | 80x80x250 80x80x500 | |

| M4 | 40x40x1000 40x45x1000 | 20x20x1000 20x20x2000 | M4 | 30x30x250 30x30x500 | 80x80x1000 80x80x2000 | ||

| M5 | 50x50x1000 50x55x1000 | M2&period5 | 25x25x250 25x25x500 | 30x30x1000 30x30x2000 | M10 | 100x100x250 100x100x500 | |

| M6 | 60x60x1000 60x65x1000 | 25x25x1000 25x25x2000 | M4 | 40x40x250 40x40x500 | 100x100x1000 100x100x2000 | ||

| M8 | 80x80x1000 | 40x40x1000 40x40x2000 |

All varieties of hoi EPT spare parts &comma GJJ&commaBAODA&commaZOOMLION&commaTIGER&comma

Driving unit with 2-motors &sol 3-motors&semi

motor&colon 11kw&comma 14&period5kw&comma18kw&semi

motor spare parts&colon braking technique&semi brake sheet&comma motor adjustor&comma electromagnet&commamotor supporter&period

security system&colon 30KN&comma40KN&comma50KN&comma60KN&semi

gearbox&colon sixteen&colon1&comma14&colon1&comma12&colon1&semi10&colon1&semi

coupling with rubber&semi

learn rollers for seventy six tube and 89 tube&semi

gear rack M8 40x60x1508mm&semi

equipment pinion&colon M8&comma15teeth&semi

restrict switch&semi

gate rollers&semi

counter rollers&semi

transformer&semi

Overload safeguard method&semi

cable&colon 3×16&plus2x6&comma 3×16&plus2x10

We sincerely wish the cooperation with you in the relative fields&excl

|

substance |

metal C45&solC60 |

| dimension | 40×60×1508mm &comma M8 |

| utilization | development elevator |

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 various branches. For much more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of authentic tools manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating product use and compatibility. Our firm and the listed substitute parts contained herein are not sponsored, approved, or made by the OEM.