Product Description

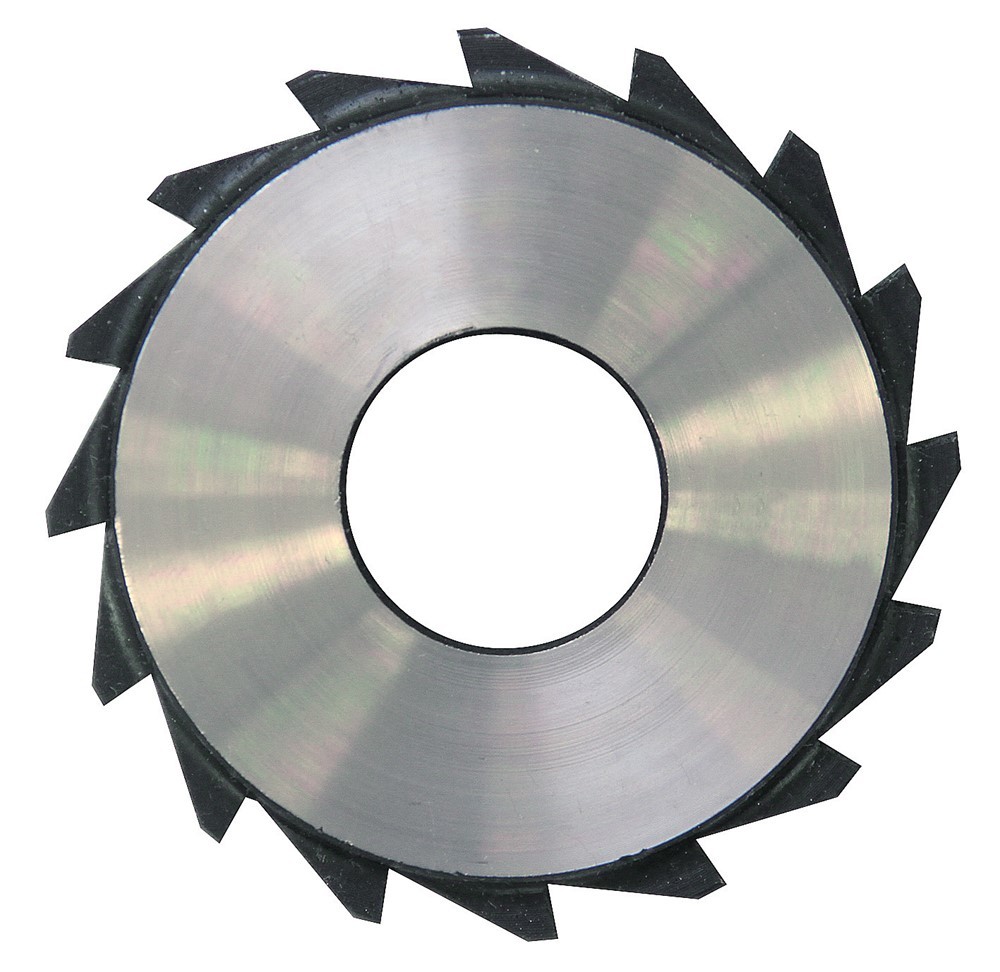

Product Name: Five Axis Machining Ratchet Pin Wheel

Company Name: HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.

Keywords: Machining Ratchet Pin Wheel, Five Axis Machining Wheel, Alloy Steel Pin Wheel, CNC Machining Parts

Description: Our Five Axis Machining Ratchet Pin Wheel is a high-quality CNC machined part made from alloy steel. It is designed for use in customized processing and packaging machines, specifically for SMD carrier tape pin wheel semiconductor vibration plate parts. Trust in our expertise at HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for precision and reliability.

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | HangZhou, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Detailed Photos

Explore our collection of detailed photos showcasing the precision and quality of our Five Axis Machining Ratchet Pin Wheel. Made from alloy steel, this CNC machined part is perfect for machines that require a reliable and durable pin wheel. Enhance your machine’s performance with our top-notch machining wheel.

Introducing the Five Axis Machining Ratchet Pin Wheel!

Get ready to revolutionize your machining experience with the incredible precision and quality of our Ratchet Pin Wheel. Manufactured by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., this cutting-edge product is designed to take your CNC machining to new heights.

Our Ratchet Pin Wheel is crafted with utmost care and expertise. It all starts with CNC turning, where the rough blank is meticulously shaped. Then, our state-of-the-art precision 5-axis CNC takes over, ensuring every detail is flawlessly executed. Finally, a sleek surface electroplating finish adds the perfect touch of sophistication.

With its alloy steel construction, our Ratchet Pin Wheel guarantees durability and longevity. It is specifically engineered to withstand the demands of heavy-duty machining, making it an ideal choice for professionals and enthusiasts alike.

Experience the benefits of our Five Axis Machining Wheel firsthand. Its exceptional design allows for seamless integration into your CNC machine, providing unparalleled performance and accuracy. Say goodbye to subpar results and hello to precision engineering at its finest.

Don’t settle for anything less than perfection. Choose our Ratchet Pin Wheel for machine and witness the difference it can make in your machining projects. Upgrade your CNC machine with the best in the industry and achieve outstanding results every time.

Introducing the Five Axis Machining Ratchet Pin Wheel

Get ready to experience precision and quality like never before with the Five Axis Machining Ratchet Pin Wheel from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This incredible product is designed to elevate your machining capabilities to new heights.

Constructed with H59 brass, the motor shaft copper sleeve is meticulously CNC turned and 5-axis CNC milled to ensure unparalleled accuracy. To top it off, the surface is expertly electroplated for a flawless finish that will impress even the most discerning eye.

With the Five Axis Machining Ratchet Pin Wheel, you’ll enjoy seamless performance and effortless operation. Its alloy steel pin wheel guarantees durability and longevity, making it the perfect choice for any CNC machining project. Whether you’re working on a ratchet pin wheel carrier or a brooch pin wheel, this versatile product has got you covered.

Don’t settle for anything less than perfection. Upgrade your machining game with the Five Axis Machining Ratchet Pin Wheel today!

Introducing the Robot Accessory Bracket by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This bracket is made of AL6061 aluminum alloy and undergoes 5-axis milling and natural surface treatment. Perfect for enhancing your robot’s functionality and durability.

Introducing the Five Axis Machining Ratchet Pin Wheel

Get ready to take your scale adjustment game to the next level with the incredible Five Axis Machining Ratchet Pin Wheel from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This high-performance tool is designed to fine-tune terminal machines and mechanical equipment with precision and ease.

Crafted from top-quality carbon steel, this ratchet pin wheel is built to last. Its high-hardness and durability ensure that it can withstand even the toughest tasks. The CNC lathe and precision 5-axis CNC processing guarantee exceptional accuracy, while the electroplated surface adds a touch of style.

With its advanced design and impeccable craftsmanship, the Five Axis Machining Ratchet Pin Wheel is a must-have for any professional or DIY enthusiast. Whether you’re working on a complex project or simply need to make precise adjustments, this tool will exceed your expectations.

Don’t settle for anything less than perfection. Upgrade your equipment with the Five Axis Machining Ratchet Pin Wheel and experience the difference it makes in your work. Order yours today and revolutionize your scale adjustment process!

Introducing the incredible Speech Microphone by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.! Crafted with precision using the finest AL6063 aluminum alloy material, this microphone is a true game-changer. With its sleek design and gold surface oxidation, it’s not just a microphone, it’s a statement!

Perfect for a variety of settings, including KTV, schools, karaoke halls, stages, speeches, and other public places, this microphone is a must-have for anyone who wants to make their voice heard. Whether you’re a professional speaker or just love to sing your heart out, this microphone will take your performance to the next level.

Thanks to the CNC lathe and 5-axis CNC processing, this microphone is built to last. It’s durable, reliable, and delivers exceptional sound quality every time. Say goodbye to muffled or distorted audio – with this microphone, your voice will shine through crystal clear.

Don’t settle for ordinary when you can have extraordinary. Upgrade your microphone game with the Speech Microphone by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. Order yours today and get ready to make a lasting impression!

[Product Name: Five Axis Machining Ratchet Pin Wheel]

[Company Name: HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.]

[Keywords: Machining Ratchet Pin Wheel, Five Axis Machining Wheel, Alloy Steel Pin Wheel, CNC Machining Parts, Ratchet Pin Wheel, Machining Brooch Pin, Pin Wheel for Machine, Five Axis Machining Cam, Ratchet Pin Wheel Carrier, CNC Machine Parts, Alloy Steel Ratchet Pin Wheel, Machining Wheel for Machine, Five Axis CNC Parts, Ratchet Wheel Pin, Machining Pin Wheel, Alloy Steel Cam Wheel, CNC Machined Parts, Ratchet Pin Wheel for Machine, Five Axis Machined Wheel, Alloy Steel Machining Parts, Machining Ratchet Wheel, CNC Parts for Machine, Ratchet Pin Wheel Cam, Machining Brooch Pin Wheel, Alloy Steel Machine Parts, CNC Machining for Machine]

Introducing the Titanium Alloy Interface

Get ready to experience the cutting-edge technology of the Titanium Alloy Interface! Crafted with precision CNC processing and 5-axis CNC processing, this interface is made from the finest Tc4 titanium alloy material. It’s not just any ordinary interface – it’s a game-changer!

Whether you need it for equipment interfaces, mechanical interfaces, or aviation plug interfaces, our Titanium Alloy Interface is designed to exceed your expectations. Its exceptional durability and strength make it the perfect choice for any application.

About Us

Welcome to HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.! With over 20 years of experience in production technology, we are a leading manufacturer that combines industry and trade. Located in HangZhou City, ZheJiang Province, China, we pride ourselves on our advanced high-end professional production and processing technology.

At Xihu (West Lake) Dis.an Hardware, we are dedicated to innovation and continuous R&D. Our team of highly skilled technical management personnel, experienced designers, and R&D experts ensures that we deliver only the highest quality products. With a perfect company management system in place, we are committed to providing you with the best.

CNC Training Parts

Looking for top-notch CNC machining parts? Look no further! Our Five Axis Machining Ratchet Pin Wheel is the ultimate choice for precision and performance. Made from alloy steel, this pin wheel is designed to withstand the toughest conditions.

Whether you need it for a machine, brooch pin, or cam, our Five Axis Machining Ratchet Pin Wheel is versatile and reliable. With its impeccable craftsmanship and attention to detail, it’s the perfect addition to any CNC machine.

Experience the difference with Xihu (West Lake) Dis.an Hardware’s CNC Machined Parts. Our commitment to CHINAMFG ensures that you receive the highest quality products that meet your exact specifications. Don’t settle for anything less than the best – choose Xihu (West Lake) Dis.an Hardware for all your CNC machining needs!

Product Name: Five Axis Machining Ratchet Pin Wheel

Company Name: HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.

Keywords: Machining Ratchet Pin Wheel, Five Axis Machining Wheel, Alloy Steel Pin Wheel, CNC Machining Parts, Ratchet Pin Wheel, Machining Brooch Pin, Pin Wheel for Machine, Five Axis Machining Cam, Ratchet Pin Wheel Carrier, CNC Machine Parts, Alloy Steel Ratchet Pin Wheel, Machining Wheel for Machine, Five Axis CNC Parts, Ratchet Wheel Pin, Machining Pin Wheel, Alloy Steel Cam Wheel, CNC Machined Parts, Ratchet Pin Wheel for Machine, Five Axis Machined Wheel, Alloy Steel Machining Parts, Machining Ratchet Wheel, CNC Parts for Machine, Ratchet Pin Wheel Cam, Machining Brooch Pin Wheel, Alloy Steel Machine Parts, CNC Machining for Machine

Description: Introducing the Five Axis Machining Ratchet Pin Wheel by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This high-quality alloy steel pin wheel is perfect for CNC machining applications. It is designed to provide precise and reliable performance, making it an essential component for any machine. Upgrade your CNC machine with this durable and efficient ratchet pin wheel today!

Introducing the Five Axis Machining Ratchet Pin Wheel!

Prepare to be amazed by the cutting-edge precision and top-notch craftsmanship of our latest creation. At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we take pride in our state-of-the-art factory, spHangZhou an impressive 2,000 square meters. Equipped with the most advanced core processing technologies, our facility is a hub of innovation and excellence.

What sets us apart is our high-end precision production equipment. We have a wide range of tools that will leave you in awe. From CNC lathes to 5-axis CNC and 4-axis CNC machines, we have it all. Our stamping equipment and die-casting equipment further enhance our capabilities, ensuring that every detail is flawlessly executed.

But that’s not all! We also offer 2.5-dimensional detection equipment, guaranteeing the utmost accuracy and quality control. With this cutting-edge technology, we leave no room for errors.

Now, let’s dive into the star of the show – the Five Axis Machining Ratchet Pin Wheel. Crafted with precision and finesse, this alloy steel pin wheel is a true masterpiece. Its CNC machining parts are meticulously designed to deliver exceptional performance.

Whether you need a ratchet pin wheel, a machining brooch pin, or a pin wheel for your machine, we’ve got you covered. Our Five Axis Machining Ratchet Pin Wheel is versatile and can be used in various applications. Its durability and reliability make it a perfect fit for any project.

Experience the power of our CNC machined parts. The ratchet pin wheel for machine is engineered to perfection, ensuring smooth operation and optimal functionality. With our Five Axis Machining Ratchet Pin Wheel, you can trust that your machine will perform at its best.

Don’t settle for anything less than excellence. Choose our alloy steel ratchet pin wheel and witness the difference it makes in your operations. Its superior quality and precision will exceed your expectations.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we are committed to providing top-of-the-line CNC machine parts. Our machining wheel for machine is a testament to our dedication to perfection. Trust us to deliver the highest quality products that meet your exact specifications.

Upgrade your machinery with our Five Axis CNC Parts. The ratchet wheel pin is designed to withstand the toughest conditions, ensuring longevity and reliability. With our machining pin wheel, you can take your projects to new heights.

Experience the power of our alloy steel cam wheel. Its CNC machined parts are built to last, offering unmatched durability and strength. Trust our alloy steel machine parts to deliver exceptional performance every time.

When it comes to CNC machining for machines, we are the experts. Our machining brooch pin wheel is meticulously crafted to meet the highest standards. With our alloy steel machining parts, you can trust that your machine will operate flawlessly.

Upgrade your machinery today with our Five Axis Machining Ratchet Pin Wheel. Experience the precision, durability, and reliability that only HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. can deliver. Trust us to take your projects to new heights!

Introducing the incredible auxiliary production equipment from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.! Get ready to be blown away by our electroplating, anodizing, hard anodizing, and surface treatment capabilities. We’ve got everything you need to take your products to the next level!

But that’s not all – our testing equipment is top-notch too. With our sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector, and other conventional testing equipment, you can be confident that your products will meet the highest standards of quality.

If you’re as excited as we are about our products, then don’t hesitate to contact us. We’re here to provide you with the best price support and quality service. Get in touch now and let’s make some magic happen!

Product Description:

Five Axis Machining Ratchet Pin Wheel

Looking for the perfect ratchet pin wheel for your machining needs? Look no further! Our Five Axis Machining Ratchet Pin Wheel is here to revolutionize your CNC machining experience.

Constructed with precision and expertise, this alloy steel pin wheel is designed to deliver exceptional performance and durability. With our state-of-the-art CNC machining technology, you can expect nothing less than perfection.

Whether you need a ratchet pin wheel for your machine or a machining brooch pin, our versatile product has got you covered. Its five-axis machining capabilities ensure precise and accurate results every time.

Don’t settle for anything less than the best. Choose our Five Axis Machining Ratchet Pin Wheel and experience the difference in quality and performance. Order yours today!

Welcome to HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.! We are thrilled to have the opportunity to establish a long-term cooperation with you. Our team is excited to discuss your requirements and ideas, so please don’t hesitate to send us pictures and letters. We can’t wait to get started!

When it comes to materials, we only work with the best. We have partnered with numerous high-quality material suppliers, ensuring that the quality of our products is guaranteed. You can choose from a wide range of materials, including aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, acrylic, and more. We can also provide supporting documents for all the materials we use.

For surface treatment, we have established long-standing relationships with our suppliers. They have extensive experience and are well-versed in meeting all quality requirements. This means that the quality of our surface treatments is stable and highly reliable. We offer a variety of surface treatments, such as heat treatment, spray painting, powder coating, blackening, silver/gold plating, electrolytic polishing, nitriding, phosphating, nickel/zinc/chromium/TiCN plating, anodizing, polishing, passivation, sandblasting, galvanizing, heat treatment, hardening, laser marking, and more. Whatever your requirements may be, we’ve got you covered!

One of our standout products is the Five Axis Machining Ratchet Pin Wheel. This precision-engineered wheel is made from alloy steel, ensuring its durability and reliability. It is perfect for use in various CNC machines and is designed to provide smooth and efficient operation. With our advanced machining techniques, we can create intricate designs and precise dimensions, guaranteeing a perfect fit for your needs.

Don’t miss out on the opportunity to enhance your machines with our top-of-the-line CNC machining parts. Our expertise in machining brooch pins, cam wheels, ratchet pin wheel carriers, and more is unmatched. We use alloy steel to ensure the highest quality and performance.

Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for all your machining needs. We are dedicated to providing exceptional products and services that meet and exceed your expectations. Contact us today and let’s embark on an exciting journey of collaboration and success!

Dust-free electroless nickel plating on carbon steel surface

Introducing the Five Axis Machining Ratchet Pin Wheel by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This CNC machined part is made of alloy steel and is perfect for use in machines. Enhance your machine’s performance with this high-quality ratchet pin wheel.

FAQ

Exciting News! Get Ready for the Ultimate Five Axis Machining Ratchet Pin Wheel!

Are you in search of the perfect machining solution? Look no further! Introducing the incredible Five Axis Machining Ratchet Pin Wheel from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This cutting-edge product is designed to revolutionize your machining experience and take your projects to new heights!

With our Five Axis Machining Ratchet Pin Wheel, you’ll enjoy unparalleled precision and efficiency. Crafted with the highest quality alloy steel, this CNC machined masterpiece guarantees exceptional durability and performance. Say goodbye to subpar results and hello to flawless machining every time!

But that’s not all! Our Ratchet Pin Wheel is not only reliable but also incredibly versatile. Whether you need it for a brooch pin, a cam wheel, or any other machining application, this product has got you covered. Its adaptability and flexibility make it the perfect choice for all your machining needs.

Worried about the hassle of getting your hands on this incredible product? Don’t be! At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we prioritize your convenience. Simply send us an inquiry email, and we’ll be in touch with you in no time. We understand that time is of the essence, so we strive to deliver your sample within 3-7 days, depending on your specific items.

When it comes to payment, we’ve got you covered too. We accept a 50% deposit, and once your goods are prepared, we’ll provide you with photos or videos for your peace of mind. For small quantities, we even accept Paypal, making the process even more convenient for you. For larger amounts, T/T is preferred.

Rest assured, your satisfaction is our top priority. We have a team of experienced engineers and a state-of-the-art workshop spHangZhou over 3,000m2. With our expertise and dedication to quality, we guarantee that you’ll receive nothing but the best. In fact, we’re so confident in our products that we offer samples before mass production, so you can see the exceptional quality for yourself!

Concerned about the safety of your drawings? Don’t be! We value your trust and confidentiality. Your drawings will be kept safe and secure, and we won’t release them to any third party without your permission.

And here’s the best part: you don’t even have to visit our company to stay updated on the progress of your products! We’ll provide you with a detailed production schedule and send you weekly reports with digital pictures and videos. You’ll be able to track the machining progress from the comfort of your own home!

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we never compromise on quality. We take pride in manufacturing only the highest quality products, ensuring your complete satisfaction. In the unlikely event that you’re not happy with your purchase, we’ll work tirelessly to make it right. Your happiness is our guarantee!

So what are you waiting for? Don’t miss out on this incredible opportunity to elevate your machining game. Get in touch with us today and experience the power of the Five Axis Machining Ratchet Pin Wheel!

Packing&Shipping

Introducing the Five Axis Machining Ratchet Pin Wheel!

Get ready to revolutionize your machining experience with our top-of-the-line product from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This incredible ratchet pin wheel is designed to take your CNC machining to the next level.

Features:

- Unleash the power of five-axis machining with our cutting-edge wheel

- Made from high-quality alloy steel for exceptional durability and performance

- Precision CNC machining ensures flawless results every time

- Perfectly designed ratchet pin wheel carrier for seamless operation

- Enhance your CNC machine with these top-notch parts

Benefits:

- Experience unparalleled precision and accuracy in your machining projects

- Effortlessly tackle complex tasks with the help of our five-axis machining wheel

- Enjoy long-lasting performance thanks to the superior quality alloy steel

- Maximize productivity and efficiency with our CNC machined parts

- Upgrade your machine with ease and achieve outstanding results

Choose from a variety of packaging options to suit your needs. Whether it’s commercial or industrial packaging, we’ve got you covered. Our team at HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. is dedicated to providing you with the best products and service.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Professional Service |

|---|---|

| Warranty: | 30 Days |

| Certification: | ISO9001, ISO, CE |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can ratchet wheels be customized for specific uses or integrated into different systems?

Yes, ratchet wheels can be customized for specific uses and seamlessly integrated into various mechanical systems. Customization allows for tailoring ratchet wheels to meet the unique requirements of specific applications. Here are ways in which ratchet wheels can be customized and integrated:

- 1. Custom Tooth Profile: Ratchet wheels can be designed with a specific tooth profile to match the desired level of control and movement. Custom tooth spacing and sizes can be created to achieve precise incremental motion or accommodate varying load capacities.

- 2. Material Selection: Depending on the application’s demands, ratchet wheels can be manufactured from different materials, including various types of metals such as steel, stainless steel, or alloys. Specialized coatings can also be applied for enhanced durability and corrosion resistance.

- 3. Size and Diameter: The size and diameter of the ratchet wheel can be customized to fit within the available space of the mechanical system. This ensures a proper fit without clearance issues or interference with other components.

- 4. Load Capacity: Custom ratchet wheels can be designed to handle specific load capacities, making them suitable for both light-duty and heavy-duty applications. Reinforced designs with larger teeth and diameters can support heavier loads.

- 5. Pawl and Catch Mechanism: The design of the pawl or catch mechanism can be tailored to ensure optimal engagement and disengagement with the custom ratchet wheel. This customization ensures reliable operation in the intended application.

- 6. Precision Requirements: For applications demanding precise control and adjustments, fine-tooth custom ratchet wheels can be created to provide finer incremental movement and enhanced accuracy.

- 7. Regulatory Compliance: Custom ratchet wheels can be designed to meet specific industry standards and safety regulations, ensuring compliance with applicable requirements.

- 8. Integration into Systems: Ratchet wheels can be seamlessly integrated into various systems, including hand tools, winches, tie-down mechanisms, conveyor systems, and more. Their unidirectional and locking capabilities make them valuable components in many applications.

Customized ratchet wheels are often used in specialized industries and applications where standard off-the-shelf components may not fully meet the unique demands. Manufacturers and engineers work closely to design and produce custom ratchet wheels that precisely match the specifications and requirements of the intended use, contributing to the efficiency and reliability of the mechanical systems they are part of.

Are there innovations or advancements in ratchet wheel technology that have emerged recently?

Yes, there have been notable innovations and advancements in ratchet wheel technology in recent years. These developments aim to enhance the performance, efficiency, and versatility of ratchet wheels in various applications. Some of the key advancements include:

- 1. Materials and Coatings: Advances in materials science have led to the development of ratchet wheels made from high-strength and lightweight materials. These materials offer improved durability and reduced wear, extending the service life of ratchet wheels. Additionally, specialized coatings are applied to enhance corrosion resistance and reduce friction.

- 2. Precision Manufacturing: Modern manufacturing techniques, including CNC machining and 3D printing, allow for the production of highly precise ratchet wheel components. This precision ensures smoother engagement and more accurate positioning, making ratchet wheels suitable for applications requiring tight tolerances.

- 3. Miniaturization: In industries like electronics and medical devices, there is a demand for smaller and more compact ratchet mechanisms. Recent advancements have led to miniaturized ratchet wheels that can operate in confined spaces while maintaining their precision and reliability.

- 4. Smart Ratchet Systems: Some innovative ratchet systems incorporate smart technology, such as sensors and feedback mechanisms. These systems can monitor the position and condition of the ratchet wheel in real-time, providing valuable data for diagnostics and maintenance.

- 5. Enhanced Safety Features: Advancements in safety-critical applications have resulted in ratchet wheels with enhanced safety features. These may include fail-safe designs, improved locking mechanisms, and more robust materials to withstand extreme conditions.

- 6. Integration with Automation: Ratchet wheels are increasingly being integrated into automated systems, where they play a crucial role in controlled motion and positioning. These integrated solutions improve efficiency and reduce the need for manual adjustments.

- 7. Customization: Manufacturers now offer greater customization options for ratchet wheels to meet specific application requirements. This includes variations in tooth profiles, sizes, and configurations to accommodate diverse needs.

- 8. Sustainable Materials: As sustainability becomes a more significant concern, there is a growing trend toward using eco-friendly materials in ratchet wheel production. This includes the use of recycled and recyclable materials in their construction.

These innovations in ratchet wheel technology contribute to their adaptability in various industries and applications. Whether it’s improving precision, enhancing safety, or reducing environmental impact, recent advancements have expanded the capabilities of ratchet wheels in mechanical systems.

What is a ratchet wheel, and how does it function in mechanical systems?

A ratchet wheel is a mechanical component that plays a crucial role in various systems by allowing unidirectional motion or preventing backward movement. It functions through a simple yet effective mechanism:

A ratchet wheel typically consists of a toothed wheel or gear with angled teeth and a corresponding pawl, which is a small lever or catch. The pawl is mounted or positioned adjacent to the ratchet wheel, and it has a pointed end that engages with the teeth on the wheel.

Here’s how a ratchet wheel functions:

- Unidirectional Motion: When an external force is applied to the system in a particular direction, the pointed end of the pawl engages with the angled teeth on the ratchet wheel. As a result, the wheel rotates freely in the direction of the applied force, allowing unidirectional motion.

- Preventing Backward Movement: However, if an attempt is made to move the system in the opposite direction, the angled teeth on the ratchet wheel lock against the pawl. The pawl prevents the wheel from rotating backward, effectively creating a mechanical “click” or “ratchet” sound and preventing reverse motion.

- Incremental Advancement: In some applications, ratchet wheels are used to provide incremental advancement. Each engagement of the pawl with a tooth on the wheel allows the wheel to move by a fixed amount or angle. This is commonly seen in tools like socket wrenches, where a ratchet mechanism allows for continuous tightening or loosening without needing to reposition the tool.

Ratchet wheels find applications in a wide range of mechanical systems, including:

- Hand Tools: Socket wrenches, screwdrivers, and pliers often feature ratchet mechanisms that enable efficient and continuous rotation in one direction while preventing backward motion.

- Winches and Hoists: Ratchet wheels are used in winches and hoists to control the winding and unwinding of cables or ropes, ensuring that loads can be raised or lowered safely and incrementally.

- Automotive Applications: Ratchet mechanisms are used in car jacks and handbrakes to secure vehicles and prevent unintended movement.

- Medical Devices: Some medical instruments use ratchet mechanisms to control the movement of specific components, ensuring precise and controlled actions.

- Industrial Machinery: Ratchet wheels are found in various industrial machines and equipment where controlled motion in one direction is essential for safety and operation.

In summary, a ratchet wheel is a mechanical device that allows unidirectional motion while preventing backward movement through the engagement of a pawl and angled teeth. Its simple yet effective design makes it a valuable component in numerous mechanical systems across various industries.

editor by CX 2023-12-22