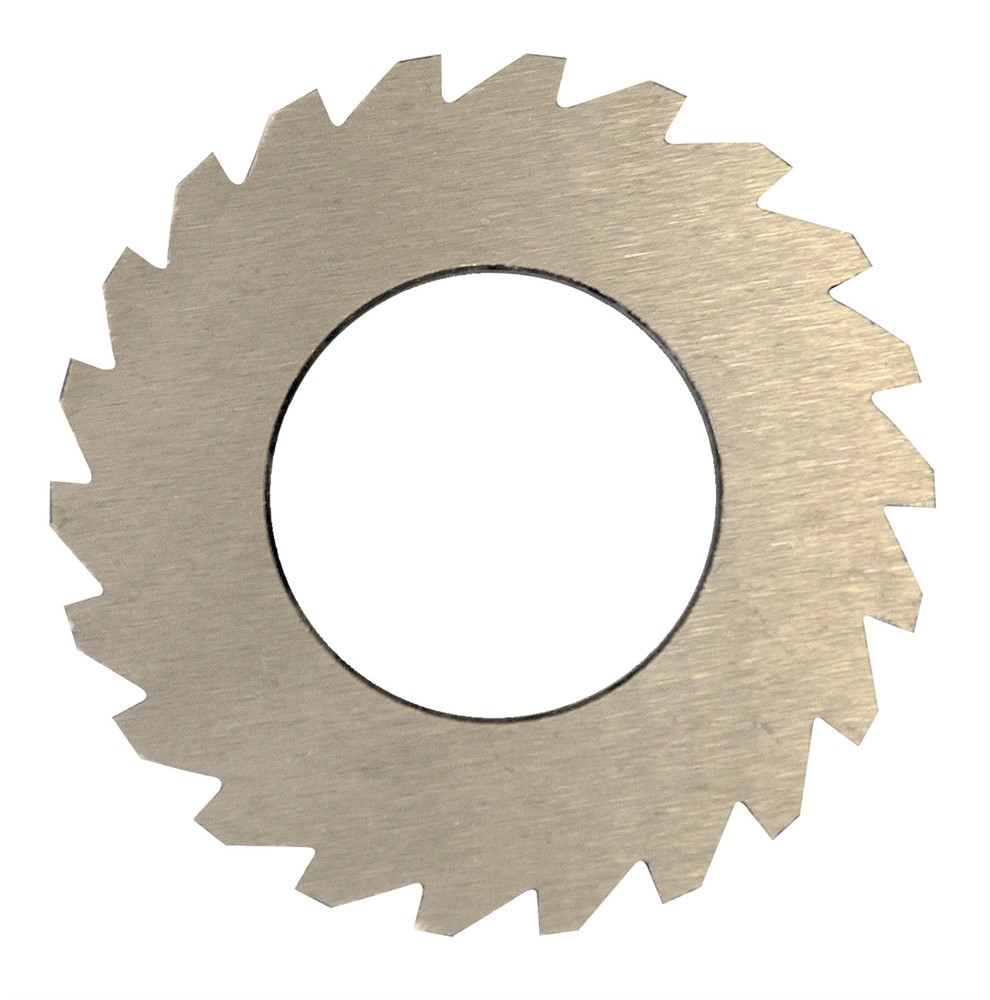

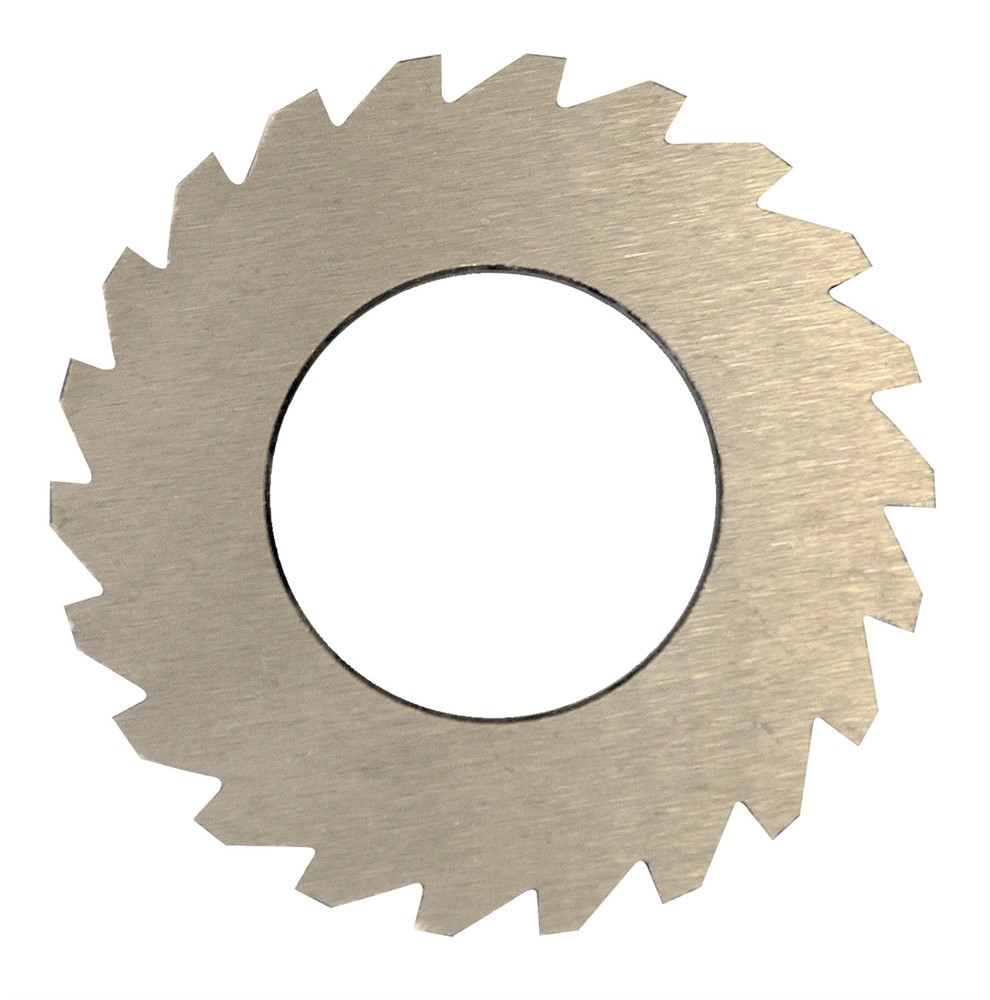

Product Description

Introducing the Carrier Tape Needle Wheel Supplier from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This precision machined part is perfect for CNC machining applications in various industries such as automotive, aerospace, and medical devices. Made from high-quality materials like aluminum, stainless steel, and brass, it ensures durability and reliability. Upgrade your machinery equipment with this custom CNC part today!

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | HangZhou, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Detailed Photos

Explore our wide range of precision machining parts, including CNC parts, milling parts, and injection molding parts. We are a trusted supplier of CNC machining components for various industries, such as automotive, aerospace, and medical devices. Our products are made from high-quality materials like aluminum, stainless steel, brass, and copper. Browse our collection for custom CNC parts and enjoy reliable performance.

Introducing the Exciting Mask Machine Knurling Wheel!

Get ready to revolutionize your mask production process with the incredible Mask Machine Knurling Wheel from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This high-quality CNC part is designed to take your manufacturing capabilities to new heights.

Our Mask Machine Knurling Wheel starts its journey as a rough blank, meticulously crafted through CNC turning. But that’s just the beginning! We then take it to the next level with precision 5-axis CNC machining, ensuring unparalleled accuracy and performance.

And the excitement doesn’t stop there! We complete the process with a flawless surface electroplating, giving the Mask Machine Knurling Wheel a stunning finish that will leave you in awe.

With our Mask Machine Knurling Wheel, you can expect nothing but the best. It’s the perfect choice for all your packaging needs, making it an essential component for any CNC parts supplier or CNC machining parts enthusiast.

Don’t miss out on this opportunity to elevate your production game. Get your hands on the Mask Machine Knurling Wheel today and experience the difference it can make in your operations.

Introducing the Motor Shaft Copper Sleeve

Get ready to experience the ultimate in precision and quality with our Motor Shaft Copper Sleeve! Crafted with utmost care and expertise by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., this copper sleeve is a game-changer in the world of CNC machining parts.

Our Motor Shaft Copper Sleeve is made from top-notch H59 brass, ensuring durability and reliability that will surpass your expectations. With precision CNC turning and 5-axis CNC milling, every detail is meticulously crafted to perfection.

But we don’t stop there! To give you the best surface treatment possible, our Motor Shaft Copper Sleeve is electroplated, adding a touch of elegance and protection. It’s the perfect combination of functionality and aesthetics.

Whether you’re in need of CNC parts, milling parts, or precision machining parts, our Motor Shaft Copper Sleeve is the ideal choice. Its versatility makes it suitable for various industries, including automotive, aerospace, and medical device machining.

Don’t settle for anything less than the best. Choose our Motor Shaft Copper Sleeve and experience the difference in quality and performance. Order yours today and revolutionize your CNC machining projects!

Introducing the Robot Accessory Bracket by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. This bracket is made of AL6061 aluminum alloy, undergoes 5-axis milling, and is finished with a natural surface treatment. Perfect for enhancing your robot’s functionality and durability.

Introducing the Fine-Tuning Dial: Elevate Your Scale Adjustment Game!

Prepare to be blown away by the incredible precision and durability of our Fine-Tuning Dial, brought to you by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. As avid readers ourselves, we understand the importance of finding the perfect balance when it comes to terminal machines and mechanical equipment. That’s why we’ve crafted this exceptional dial using high-hardness and long-lasting carbon steel.

Our Fine-Tuning Dial is a true masterpiece, meticulously processed using state-of-the-art CNC lathe and precision 5-axis CNC technology. And to top it all off, we’ve given it a sleek electroplated surface, adding a touch of elegance to its already impressive features.

Whether you’re in need of CNC parts, milling parts, or packing machine ratchets, our Fine-Tuning Dial has got you covered. It’s the ultimate solution for all your scale adjustment needs. And with our extensive range of machining components, including precision machining parts, machined metal parts, and custom CNC parts, you’ll never have to compromise on quality.

Don’t settle for anything less than perfection. Choose the Fine-Tuning Dial from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. and experience the difference it can make in your reading habits. Elevate your scale adjustment game today!

Introducing the Speech Microphone: a game-changer for all your public speaking needs! Crafted with precision using the finest AL6063 aluminum alloy material, this microphone is a true masterpiece. Our skilled technicians have employed state-of-the-art CNC lathe and 5-axis CNC technology to ensure unparalleled quality. And to top it off, the surface is elegantly oxidized with a luxurious gold finish.

Whether you’re belting out tunes at a KTV, enlightening young minds in schools, rocking the stage at a karaoke hall, or delivering a powerful speech, our Speech Microphone is your perfect companion. Designed for use in various public places, it guarantees exceptional performance and crystal-clear sound.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we take pride in being a leading CNC Parts Supplier. With our expertise in CNC Machining Parts, Five-Axis CNC Machining, Four-Axis CNC Machining Parts, Milling Parts, and more, we ensure that every component of our Speech Microphone is of the highest quality.

So why wait? Elevate your speaking experience with our Speech Microphone. It’s time to make a statement and captivate your audience like never before. Get yours today from the trusted Carrier Tape Needle Wheel Supplier, HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.

Introducing Our Titanium Alloy Interface

Get ready to experience the ultimate in precision and durability with our Titanium Alloy Interface! Crafted from Tc4 titanium alloy material using state-of-the-art CNC processing and 5-axis CNC technology, this interface is a game-changer in the world of equipment, mechanical, and aviation plug interfaces.

About Us

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we are more than just a manufacturer – we are industry pioneers with over 20 years of production technology expertise. Located in HangZhou City, ZheJiang Province, China, we pride ourselves on our advanced high-end professional production and processing technology. Our commitment to innovative R&D and production has led us to assemble a team of highly skilled technical management personnel, experienced designers, and R&D experts, all supported by a flawless company management system.

CNC Training Parts

As a leading CNC Parts Supplier, we offer a wide range of CNC machining parts to meet your needs. Our expertise includes Five-Axis CNC Machining, Four-Axis CNC Machining, Milling Parts, and more. Whether you require precision machining parts, machined metal parts, or custom CNC parts, we have you covered. Our capabilities extend to Injection Molding Parts, Plastic Machining Parts, Aluminum Machining Parts, Stainless Steel Machining Parts, Brass Machining Parts, Steel Machining Parts, Copper Machining Parts, Fiber Optic Machining Parts, Electronic Components Machining, Automotive Machining Parts, Aerospace Machining Parts, and Medical Device Machining.

Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. as your trusted CNC Parts Supplier and experience the difference in quality and performance. Contact us today to learn more about our Carrier Tape Needle Wheel Supplier and other exceptional products!

5-Axis CNC Workshop

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we specialize in providing high-quality CNC machining parts. Our workshop is equipped with advanced 5-axis CNC machines, allowing us to offer precision machining for a wide range of materials, including aluminum, stainless steel, brass, and more. Whether you need custom CNC parts for the automotive, aerospace, or medical device industry, we have the expertise to meet your requirements. Contact us today for all your CNC machining needs.

Introducing Our Exciting Carrier Tape Needle Wheel Supplier!

Prepare to be amazed by the cutting-edge capabilities of HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.! Our factory, spHangZhou an impressive 2,000 square meters, is a powerhouse of innovation and precision. We are masters of core processing technologies, and our state-of-the-art equipment will leave you in awe.

Get ready to experience the future of manufacturing with our high-end precision production equipment. We have a wide range of tools at our disposal, including CNC lathes, 5-axis CNC machines, 4-axis CNC machines, stamping equipment, and die-casting equipment. These machines are the epitome of excellence, ensuring unparalleled precision and quality in every product we create.

But that’s not all! Our 2.5-dimensional detection equipment takes quality control to a whole new level. With this cutting-edge technology, we guarantee that every single product meets the highest standards of perfection.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we are proud to be your go-to CNC Parts Supplier. Whether you need CNC Machining Parts, Five-Axis CNC Machining, Four-Axis CNC Machining Parts, Milling Parts, or any other precision machining components, we’ve got you covered. Our expertise extends to a wide range of materials, including aluminum, stainless steel, brass, steel, copper, and even fiber optic and plastic machining parts.

Our products find applications in various industries, from automotive and aerospace to medical devices and electronic components. No matter the sector, our machined metal parts are guaranteed to exceed your expectations.

So why wait? Join the ranks of satisfied customers who have experienced the exceptional quality and service of HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. Get in touch with us today and let us revolutionize your manufacturing process!

Introducing the Exciting Three-Dimensional Imager!

Are you ready to take your production to the next level? Look no further than HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. We are thrilled to present our latest innovation – the Three-Dimensional Imager! With this cutting-edge equipment, you can revolutionize your auxiliary production processes like never before.

Immerse yourself in the world of electroplating, anodizing, hard anodizing, and surface treatment with our top-of-the-line imager. It’s designed to provide you with unparalleled precision and accuracy, ensuring flawless results every time. Say goodbye to guesswork and hello to perfection!

But that’s not all – we don’t just stop at exceptional performance. At HangZhou Xihu (West Lake) Dis.an, we believe in providing our customers with the best experience possible. That’s why we offer a complete range of testing equipment to complement our Three-Dimensional Imager. From sophisticated three-dimensional testing to two-dimensional testing, hardness testing, height measurement, and projection, we’ve got you covered. With our comprehensive testing capabilities, you can be confident in the quality of your products.

So, if you’re as excited as we are about our products, don’t hesitate to reach out to us. We’re here to provide you with the best price support and quality service. Contact us now and let’s embark on a journey of CHINAMFG together!

Product Description:

Three-Dimensional Imager

Take your auxiliary production to new heights with our state-of-the-art Three-Dimensional Imager! Designed by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., this revolutionary equipment is perfect for electroplating, anodizing, hard anodizing, and surface treatment.

Featuring unparalleled precision and accuracy, our imager ensures flawless results every time. Say goodbye to guesswork and hello to perfection!

But that’s not all – we go above and beyond to provide you with the best experience possible. Our complete range of testing equipment, including sophisticated three-dimensional testing, two-dimensional testing, hardness testing, height measurement, and projection, guarantees the highest quality standards for your products.

Don’t miss out on this exciting opportunity! Contact us now for the best price support and quality service.

We are thrilled to announce our partnership with HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd.! Get ready for an exciting and long-lasting collaboration that will exceed all your expectations.

We are proud to work with a wide range of top-notch material suppliers, ensuring the highest quality for our products. You can confidently choose from our extensive selection of materials, including aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, acrylic, and more. Rest assured, we provide supporting documents for all materials, giving you peace of mind.

Our materials include Aluminum 6061/6063/7075, Iron 1215/45/1045, Stainless steel 303/304/316, Copper, Brass, Bronze (H59/H62/T2/H65), and Plastic POM/PE/PSU/PA/PEEK, among others. We are dedicated to meeting your specific requirements and delivering exceptional results.

When it comes to surface treatment, we have established long-standing partnerships with experienced suppliers who understand our quality standards inside out. You can trust us to provide stable and guaranteed quality. Our surface treatment options include heat treatment, spray painting, powder coating, blackening, silver/gold plating, electrolytic polishing, nitriding, phosphating, nickel/zinc/chromium/TiCN plating, anodizing, polishing, passivation, sandblasting, galvanizing, heat treatment, hardening, and laser marking. We are committed to fulfilling your customization needs.

Don’t hesitate to reach out to us with any questions or to discuss your requirements. We welcome your pictures and letters as we embark on this exciting journey together. Thank you for choosing us as your trusted partner!

Product Description:

Carrier Tape Needle Wheel Supplier

Looking for a reliable CNC Parts Supplier? Look no further! HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. is your go-to source for CNC Machining Parts. With our expertise in Five-Axis CNC Machining and Four-Axis CNC Machining, we deliver precision and quality like no other.

Our extensive range of services includes Milling Parts Supplier, Packing Machine Ratchet Supplier, Needle Wheel Supplier, and Carrier Tape Supplier. We specialize in CNC Machining Components, Precision Machining Parts, Machined Metal Parts, Custom CNC Parts, Injection Molding Parts, Plastic Machining Parts, Aluminum Machining Parts, Stainless Steel Machining Parts, Brass Machining Parts, Steel Machining Parts, Copper Machining Parts, Fiber Optic Machining Parts, Electronic Components Machining, Automotive Machining Parts, Aerospace Machining Parts, and Medical Device Machining.

Dust-free electroless nickel plating on carbon steel surface.

FAQ

Exciting News! Get Ready to Discover the Perfect Product for Your Needs!

Q1: Are you wondering where you can find detailed product and price information? Look no further! Simply send us an inquiry e-mail, and we’ll be thrilled to get in touch with you as soon as we receive your mail.

Q2: How long will it take to get your hands on a sample? Well, it depends on the specific items you’re interested in. But don’t worry, we strive to deliver within 3-7 days, so you won’t have to wait long to experience our amazing products!

Q3: Want to know what information we need to provide you with a quote? It’s super easy! Just kindly provide us with the product drawings in PDF format. If you have them in STEP or IGS, even better! We want to make sure we give you the most accurate and competitive quote possible.

Q4: Now, let’s talk payment terms. We accept a 50% payment deposit. Once your goods are prepared, we’ll even shoot photos or videos for you to check. Then, you can pay the balance and get ready to enjoy your top-notch products. For small quantities, we accept Paypal, with the commission added to the order. For larger amounts, T/T is preferred.

Q5: How will your goods be delivered? We’ve got you covered! We deliver our products through a reliable courier company, ensuring that they reach you safely and on time.

Q6: Curious about who we are? We’re not just any trading company – we’re a factory direct with 17 experienced engineers and over 50 dedicated employees. With our impressive 3,000m2 workshop area, we have all the resources needed to create exceptional products just for you!

Q7: Don’t have drawings? No problem at all! Simply send us a sample, and we’ll work our magic to provide you with better solutions. You can also send us pictures or drafts with dimensions, and we’ll create CAD or 3D files for you. We’re here to make your vision a reality!

Q8: Exciting news! You can absolutely get some samples before mass production. We want you to be confident in the quality and CHINAMFG of our products, so go ahead and request those samples!

Q9: Worried about the safety of your drawings? Rest assured, we take your privacy seriously. Your drawings will be kept safe and secure, and we won’t release them to any third party without your permission.

Q10: Want to stay updated on the progress of your products without having to visit our company? We’ve got you covered! We’ll provide you with a detailed production schedule and send you weekly reports with digital pictures and videos. You’ll be able to see the machining progress firsthand!

Q11: Quality is our top priority! We never compromise on the quality of our products. We’re confident that you’ll be more than satisfied with the exceptional quality we deliver. Your happiness is our success!

So, what are you waiting for? Get in touch with us today and let’s embark on an exciting journey together! Discover the perfect product that will exceed your expectations. Trust in HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. to provide you with the best CNC parts, machining components, and so much more. Don’t miss out on this incredible opportunity!

Packing&Shipping

Exciting Product Description

Introducing the Amazing Carrier Tape Needle Wheel Supplier!

Are you in need of top-quality CNC parts for your projects? Look no further! HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. proudly presents our incredible Carrier Tape Needle Wheel Supplier. With our expertise in CNC machining and precision engineering, we guarantee exceptional performance and reliability.

Unleash Your Creativity with Our CNC Machining Parts

Our CNC Machining Parts are designed to meet the highest standards of quality and precision. Whether you’re working on a five-axis or four-axis CNC machine, our parts will ensure smooth and accurate operations. From milling parts to packing machine ratchets, we have everything you need to bring your ideas to life.

Unmatched Durability and Versatility

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we understand the importance of durable and versatile machining components. That’s why our Machined Metal Parts are crafted with the finest materials, including aluminum, stainless steel, brass, steel, copper, and even fiber optic materials. No matter the industry, from automotive to aerospace and medical devices, our parts will exceed your expectations.

Customized Solutions for Your Unique Needs

We believe in providing tailored solutions to our customers. Our team of experts is ready to assist you in creating custom CNC parts that perfectly match your requirements. Whether you need injection molding parts or plastic machining parts, we have the expertise to deliver outstanding results.

Order Now and Experience Excellence

Don’t miss out on the opportunity to enhance your projects with the finest CNC machining parts. Place your order for the Carrier Tape Needle Wheel Supplier from HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. today! Experience CHINAMFG in every detail and take your creations to new heights.

| After-sales Service: | Professional Service |

|---|---|

| Warranty: | 30 Days |

| Condition: | New |

| Certification: | RoHS, ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do ratchet wheels differ from other types of gears in terms of functionality?

Ratchet wheels differ from other types of gears in terms of functionality primarily due to their unidirectional motion and ability to prevent backward movement. Here are key distinctions between ratchet wheels and other gears:

- 1. Unidirectional Motion: Ratchet wheels are designed to allow motion in only one direction. When force is applied in the desired direction, the ratchet wheel rotates freely, enabling movement. In contrast, traditional gears, such as spur gears or helical gears, transmit motion bidirectionally—both clockwise and counterclockwise.

- 2. Prevention of Backward Movement: The defining feature of ratchet wheels is their ability to prevent backward movement. This is achieved through the engagement of a pawl or catch mechanism with the teeth of the ratchet wheel. The pawl locks the ratchet wheel in place when force is applied in the opposite direction, effectively preventing any reverse motion. Traditional gears do not have this locking capability and allow bidirectional movement without restriction.

- 3. Incremental Motion Control: Ratchet wheels are often used in applications where precise incremental motion control is required. The teeth on a ratchet wheel are typically spaced in a way that allows for controlled, step-by-step movement. This is advantageous in scenarios where precise positioning or adjustments are necessary, such as in ratchet wrenches or fine-tooth ratchet wheels.

- 4. Limited Gear Ratio: Unlike traditional gears that can provide variable gear ratios to change speed and torque, ratchet wheels offer a fixed gear ratio. They are not used for speed reduction or torque amplification but rather for controlled and secure movement in one direction.

- 5. Specialized Applications: Ratchet wheels are commonly found in specific applications where their unidirectional and locking capabilities are crucial. These include hand tools like ratchet wrenches, winches, tie-down straps, handbrakes in vehicles, and more. Traditional gears are used in a broader range of applications where bidirectional motion is needed, such as in machinery, vehicles, and industrial equipment.

In summary, ratchet wheels excel at providing controlled, unidirectional motion and preventing backward movement. They are specialized components used in applications where these characteristics are essential. Traditional gears, on the other hand, are versatile components that transmit motion bidirectionally and are employed in a wide array of mechanical systems for various purposes.

What safety considerations should be taken into account when using ratchet wheels in various settings?

When using ratchet wheels in various settings, it is crucial to prioritize safety to prevent accidents and ensure the well-being of operators. Here are essential safety considerations to keep in mind:

- 1. Proper Installation and Alignment: Ensure that ratchet wheels are correctly installed and aligned with their accompanying pawls or catches. Misalignment or improper installation can lead to unreliable operation and safety hazards.

- 2. Regular Inspection and Maintenance: Implement a routine inspection and maintenance schedule for ratchet wheels and their associated components. Look for signs of wear, damage, or misalignment, and address issues promptly to prevent accidents.

- 3. Load Capacity: Adhere to the specified load capacity of the ratchet wheel and the entire system. Overloading can cause failures, leading to dangerous situations. Always consider the maximum load when selecting and using ratchet wheels.

- 4. Operator Training: Ensure that operators are adequately trained in the safe use of ratchet wheel systems. Training should cover proper operation, load limits, and safety procedures in case of emergencies.

- 5. Emergency Stop Mechanisms: In applications where ratchet wheels are used as safety interlocks or emergency stop devices, ensure that these mechanisms are reliable and regularly tested. In emergencies, they should halt operations immediately and effectively.

- 6. Lockout/Tagout Procedures: Develop and implement lockout/tagout procedures when working on equipment that includes ratchet wheels. This ensures that machinery is de-energized and cannot be inadvertently started during maintenance or repair activities.

- 7. PPE (Personal Protective Equipment): Provide and require the use of appropriate personal protective equipment, such as gloves and safety glasses, when working with or near ratchet wheel systems. PPE can reduce the risk of injuries in case of accidents.

- 8. Hazard Identification: Identify potential hazards associated with the use of ratchet wheels, including pinch points, sharp edges, and moving parts. Implement guards and warning signs to minimize risks.

- 9. Environmental Conditions: Consider the environmental conditions in which ratchet wheels are used. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized equipment and safety precautions.

- 10. Regular Testing and Certification: Periodically test and certify the safety mechanisms and components associated with ratchet wheels. This ensures that they meet industry standards and function as intended.

- 11. Risk Assessment: Conduct a risk assessment specific to the application of ratchet wheels. Identify potential risks and implement control measures to mitigate them effectively.

- 12. Compliance with Regulations: Be aware of and comply with relevant safety regulations, standards, and guidelines specific to your industry or region. Non-compliance can lead to legal and safety issues.

- 13. Emergency Response Plan: Develop an emergency response plan that outlines procedures for dealing with accidents or malfunctions involving ratchet wheel systems. Ensure that all personnel are familiar with this plan.

By incorporating these safety considerations into the use of ratchet wheels, you can help minimize risks, protect personnel, and ensure a safer working environment across various settings.

In what mechanical devices or tools are ratchet wheels commonly used, and how do they operate?

Ratchet wheels are commonly used in various mechanical devices and tools, where they play a crucial role in enabling unidirectional motion and preventing backward movement. Here are some examples of mechanical devices and tools that incorporate ratchet wheels and an explanation of how they operate:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, are widely used in automotive repair and mechanical work. They feature a ratchet wheel mechanism in the wrench head. When the user turns the handle in one direction, the ratchet wheel engages with the socket, allowing continuous rotation for fastening or loosening bolts or nuts. When the direction is reversed, the ratchet wheel disengages, preventing backward motion and allowing the user to reposition the wrench without removing it from the fastener.

- 2. Ratchet Straps and Tie-Downs: Ratchet straps and tie-downs are used for securing cargo on trucks, trailers, and in various transportation applications. They consist of a ratchet mechanism and a strap with hooks. By cranking the ratchet handle, the ratchet wheel tightens the strap, providing secure tension. The ratchet prevents the strap from unwinding or loosening during transit, ensuring that the load remains securely fastened.

- 3. Handbrakes in Vehicles: In automobiles, ratchet wheels are a fundamental component of handbrakes (parking brakes). When the handbrake lever is pulled, it engages a ratchet mechanism that locks the rear wheels in place, preventing the vehicle from rolling when parked on an incline. Releasing the handbrake disengages the ratchet, allowing normal wheel rotation.

- 4. Winches and Hoists: Winches and hoists used in industries such as construction, manufacturing, and material handling rely on ratchet wheel mechanisms. The ratchet wheel controls the winding and unwinding of cables or ropes. When the user operates the winch or hoist in one direction, the ratchet allows the cable to be pulled in and wound onto a drum. In the opposite direction, the ratchet prevents the cable from unwinding, ensuring controlled load handling.

- 5. Bike Gears: Bicycle gears often use ratchet mechanisms to control gear shifting. When a cyclist pedals forward, the ratchet wheel engages with the gear sprocket, allowing the chain to move smoothly and propel the bike. If the cyclist pedals backward or stops pedaling, the ratchet prevents the chain from moving in reverse, ensuring efficient pedaling and preventing the bike from rolling backward.

- 6. Fishing Reels: Many fishing reels, including spinning reels and baitcasting reels, incorporate ratchet mechanisms. The ratchet wheel in the reel allows the fishing line to be pulled in when the angler reels in a fish. The ratchet prevents the line from spooling out when there is no tension on it, ensuring that the line remains taut during fishing.

In each of these applications, the ratchet wheel functions by engaging with a pawl or catch mechanism. When force is applied in the desired direction, the pawl allows the ratchet wheel to rotate freely, enabling the intended motion. When force is applied in the opposite direction, the pawl engages with the teeth on the ratchet wheel, locking it in place and preventing backward movement. This simple yet effective mechanism provides controlled and safe operation in various mechanical devices and tools.

editor by CX 2023-12-14