Product Description

163X85mm Manual Sanding Block Sanding Holder Hand CHINAMFG Tool

* PRODUCT PICTURE

* MORE PRODUCTS

1) 1”~ 6” Air Orbital Sander/Polisher (USA, Europe, Japan, ZheJiang Quality)

2) 2”~9 ” Air Angle Grinder (Japan&ZheJiang Quality)

3) Air Die Grinder (Japan&ZheJiang Quality)

4) Air Micro Grinder / Air Pencil Grinder

5) Air Screwdriver

6) Air Impact Wrench

7) Air Ratchet Wrench

8) Air Belt Sander

9) Air Drawing Machine

10) Air File

11) Air Saw

12) Air Squeezer

13) Air Pull Setter / Air Riveter

14) Air Drill

15) Air Spray Gun

16) Oil Pulse Air Tools

16) Air Squeeze Riveter

17) Air Chipping Hammer

18) Air Carton-Waste Stripper

19) Sanding Backup Pad

20) Sand Paper

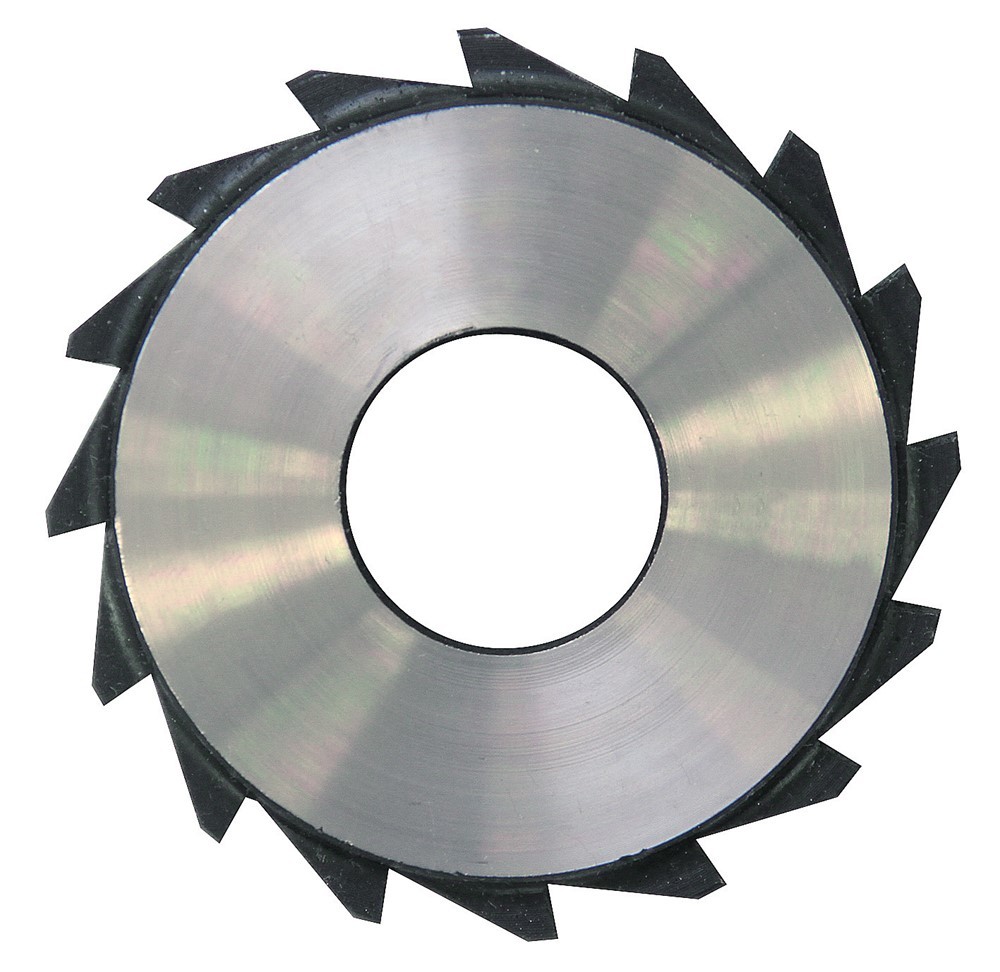

21) Grinding Wheel

22) Wool/Sponge/Foam Buffing Pad

23) Mounted Points

24) Riveting Nut, Pop Rivet

25) Car Care Poducts

25) All Tools Spare Parts

Etc…

*WHY CHOOSE US

1. Superior Quality & Competitive Prices

–We’re the first manufacturer in China to make professional-level AIR TOOLS&ABRASIVES. We have enough experience in making quality products with competitive prices.

2. Best Service

–We provide you with the best service. All tools spare parts available for aftersales service and we can teach you how to repair tools with videos or detailed repairing manual in pdf; Technical solution will be given in time if you meet any problem. Short lead time to prepare your orders and let you receive the products ASAP; We are almost 18 hours online every day.

3. Strong QC System

–We have a strong quality-control team to inspect every product and make sure they are 100% perfect before sending to customers.

4. Bright Future Cooperation

–We keep improving, innovating and creating products. So your product range will be widen and widen and more professional. Our strong sales team can teach you how to sell and where sell to.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Abrasive: | Superabrasive |

|---|---|

| Shapes: | Section Shape |

| Types: | Surface Grinding Wheel |

| Grain Size: | 36# |

| Working Style: | Surface Grinding |

| Wheel Diameter: | 4.5inch (115mm) |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the choice of materials impact the durability and performance of ratchet wheels?

The choice of materials significantly impacts the durability and performance of ratchet wheels in mechanical systems. Different materials offer varying levels of strength, wear resistance, and corrosion resistance, influencing how well the ratchet wheel performs over time. Here’s how material selection affects ratchet wheel characteristics:

- 1. Strength and Load Capacity: The material of a ratchet wheel determines its strength and load-bearing capacity. High-strength materials like hardened steel or alloy steel are often chosen for heavy-duty applications, as they can withstand substantial loads without deformation or failure.

- 2. Wear Resistance: Ratchet wheels are subject to wear and friction as they engage with pawls or catches. Materials with excellent wear resistance, such as hardened steel or materials with special coatings, can prolong the lifespan of the ratchet wheel by reducing wear and preventing premature tooth damage.

- 3. Corrosion Resistance: In environments where exposure to moisture, chemicals, or corrosive substances is a concern, selecting corrosion-resistant materials is crucial. Stainless steel and certain alloys are known for their resistance to rust and corrosion, making them suitable for such conditions.

- 4. Weight Considerations: The material’s density impacts the weight of the ratchet wheel. Lighter materials, such as aluminum or certain plastics, can be chosen when weight reduction is a priority, especially in applications where portability or reduced inertia is essential.

- 5. Friction and Efficiency: The material’s surface properties can affect friction and overall efficiency. Some materials may require lubrication to reduce friction, while others have inherent properties that promote smooth engagement and reduce energy losses.

- 6. Cost and Availability: Material choice also affects the cost and availability of ratchet wheels. Common materials like steel are readily available and cost-effective, while specialized materials may be more expensive and less accessible.

- 7. Temperature Resistance: For applications in extreme temperature environments, materials must be chosen that can withstand temperature variations without deformation or loss of mechanical properties.

- 8. Compatibility with Pawls: The material of the ratchet wheel should be compatible with the material of the pawl or catch mechanism to ensure proper engagement and prevent premature wear of either component.

Ultimately, the choice of material should align with the specific requirements of the application. Engineers and designers carefully consider factors such as load capacity, wear resistance, environmental conditions, and cost to select the most suitable material for ratchet wheels, ensuring optimal durability and performance in the intended use.

What are the signs that indicate a need for ratchet wheel replacement or maintenance, and how can they be diagnosed?

Recognizing the signs that indicate the need for ratchet wheel replacement or maintenance is crucial for ensuring the reliability and safety of mechanical systems. Here are common signs and how to diagnose them:

- 1. Excessive Wear: Check the ratchet wheel’s teeth for signs of excessive wear or rounding. If the teeth are visibly worn down, it’s an indication that the ratchet wheel may not engage properly and should be replaced.

- 2. Irregular Tooth Engagement: During operation, if you notice irregular engagement of the ratchet wheel with the pawl or catch, it may indicate misalignment, damage, or wear. Investigate and address the issue to prevent further damage.

- 3. Slippage: If the ratchet wheel slips when subjected to a load within its specified capacity, it’s a clear sign of wear or damage. This can compromise the safety and reliability of the system and warrants immediate attention.

- 4. Unintended Movement: In applications where a ratchet wheel is used to prevent unintended movement or reverse motion, any unexpected movement suggests a problem. This may be due to wear, damage, or a malfunctioning pawl mechanism.

- 5. Noise and Vibration: Unusual noises, such as grinding or rattling, or excessive vibration during ratchet wheel operation can indicate issues with teeth engagement, misalignment, or worn components.

- 6. Difficulty in Turning: If the ratchet wheel becomes difficult to turn, it may be due to increased friction caused by wear or contamination. This can lead to inefficient operation and should be addressed.

- 7. Visual Inspection: Regularly inspect the ratchet wheel for visible damage, cracks, or deformities. Any visible defects should be taken as a sign that maintenance or replacement is needed.

- 8. Pawl or Catch Condition: Examine the condition of the pawl or catch that interacts with the ratchet wheel. Signs of wear or damage on the pawl can affect the engagement and should be addressed.

- 9. Reduced Efficiency: If the ratchet wheel system is no longer operating with the same level of precision and efficiency as before, it may be an indication of wear or misalignment.

- 10. Routine Maintenance Schedule: Implement a routine maintenance schedule for ratchet wheel systems. Regular maintenance can help identify early signs of wear or issues before they become critical.

- 11. Load Testing: Conduct load testing to ensure that the ratchet wheel can handle its specified load capacity without slipping or exhibiting signs of stress. Any failures during load testing should prompt maintenance or replacement.

Diagnosing the need for ratchet wheel replacement or maintenance often involves a combination of visual inspection, functional testing, and a good understanding of the system’s expected performance. Addressing issues promptly can prevent failures and improve the safety and reliability of mechanical systems.

How does the design of a ratchet wheel contribute to its efficiency and reliability?

The design of a ratchet wheel is critical to its efficiency and reliability in various applications. The following design elements contribute to the effectiveness of ratchet wheels:

- 1. Tooth Profile: The shape and profile of the teeth on a ratchet wheel are crucial. Teeth are typically angled to allow easy engagement with the pawl or catch mechanism when force is applied in the desired direction. The angle of the teeth ensures efficient and secure movement in one direction while preventing backward motion.

- 2. Material Selection: The choice of materials for the ratchet wheel affects its durability and reliability. Ratchet wheels are commonly made of strong and wear-resistant materials such as hardened steel or alloy metals. High-quality materials ensure the wheel can withstand the forces and wear associated with its intended application.

- 3. Tooth Size and Spacing: The size and spacing of the teeth on a ratchet wheel are designed to optimize performance. Smaller teeth allow for finer control and incremental movement, while larger teeth provide stronger engagement for heavier loads. Proper tooth spacing ensures smooth and reliable operation.

- 4. Pawl Design: The design of the pawl or catch mechanism that engages with the ratchet wheel is equally important. The pawl should have a pointed end that effectively grips the teeth when engaged. It should also release easily when force is applied in the opposite direction to allow smooth and reliable operation.

- 5. Lubrication and Maintenance: Adequate lubrication of the ratchet wheel and pawl is essential for reducing friction and wear. Regular maintenance, including cleaning and re-lubrication, ensures the efficient functioning of the ratchet mechanism over time.

- 6. Load Capacity: The design of the ratchet wheel must align with the intended load capacity of the application. Heavier loads may require larger and more robust ratchet wheel designs with deeper teeth to withstand greater forces without slipping.

- 7. Durability and Corrosion Resistance: In applications where exposure to harsh environments or moisture is a concern, ratchet wheels may incorporate coatings or materials that enhance corrosion resistance. This contributes to their long-term reliability.

The combination of these design considerations ensures that a ratchet wheel can efficiently transmit motion in one direction while effectively locking to prevent reverse movement. Proper design contributes to the overall efficiency, reliability, and safety of mechanical systems and tools that rely on ratchet mechanisms.

editor by CX 2024-01-11