Product Description

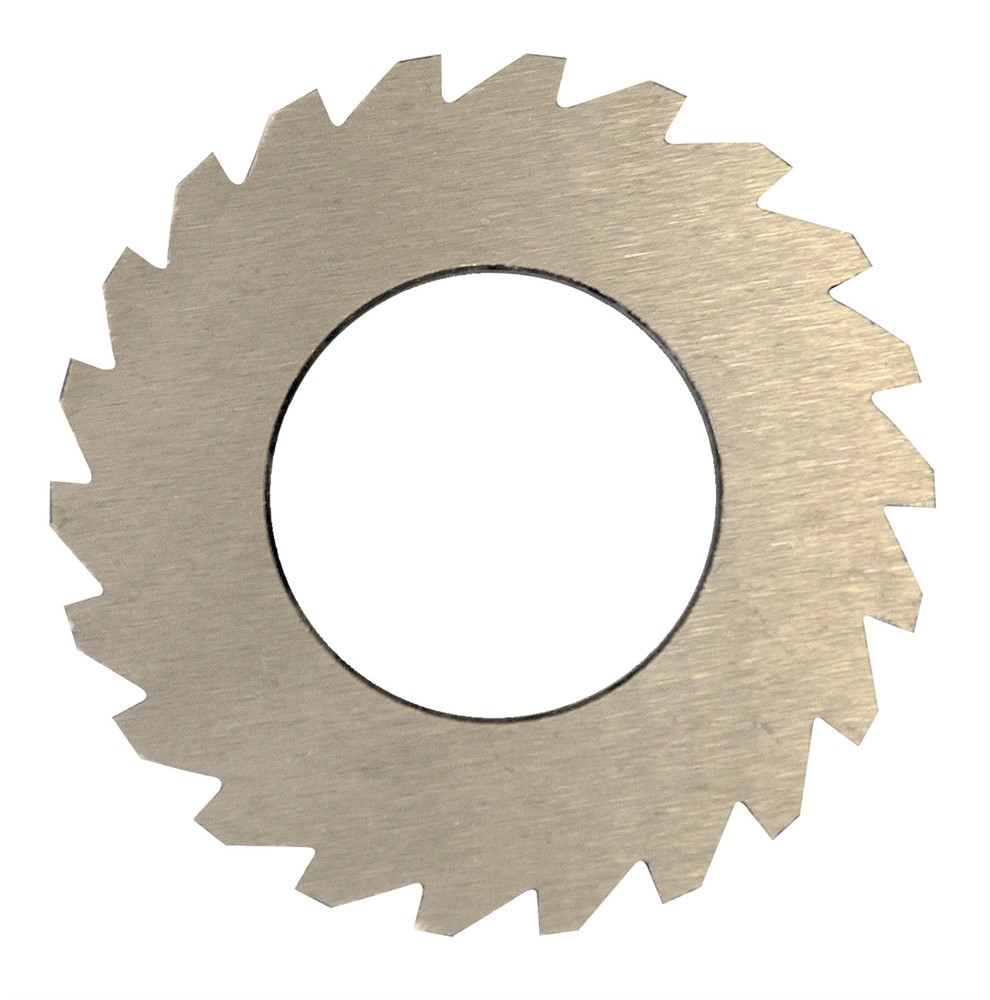

Ratchet Pin Wheel for SMD Carrier Tape

Discover our high-quality ratchet pin wheel designed for SMD carrier tape processing and packaging machines. Made from durable alloy steel, this precision-machined pin wheel ensures smooth and reliable operation. Upgrade your equipment with our CNC parts for SMD carriers today!

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy | ±0.05mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | HangZhou, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Product Parameters

Discover our high-quality Cam Machining Parts for Semiconductor Vibration Plate. Made from alloy steel, these precision components are perfect for the semiconductor industry. With our advanced machining technology, we provide reliable and custom CNC parts for your needs.

Calm and Soothing Product Description: Cam Machining Parts for Semiconductor Vibration Plate

Introducing the Cam Machining Parts for Semiconductor Vibration Plate, brought to you by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. Our high-quality machining parts are designed to enhance the performance of your semiconductor vibration plate, providing you with reliable and efficient solutions for your semiconductor manufacturing needs.

Our precision cam components are meticulously crafted using advanced machining technology. The alloy steel construction ensures durability and longevity, making these parts a reliable choice for your cam wheel assembly. With our custom CNC parts, you can expect precise and accurate machining, guaranteeing optimal performance.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we understand the importance of precision in the semiconductor industry. That’s why our cam machining accessories, such as the pulling wheel, carrier pin wheel, and ratchet, are manufactured with utmost care and attention to detail. These components play a crucial role in the smooth operation of your vibration plate, ensuring consistent and reliable performance.

With our expertise in precision machining, we offer machining services that meet the highest standards. Our CNC parts are processed using CNC turning and precision 5-axis CNC, resulting in a rough blank that is then surface electroplated for a flawless finish. This meticulous process guarantees the quality and reliability of our machining parts.

Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. as your trusted machining supplier for all your semiconductor vibration plate needs. Experience the benefits of our high-quality cam machining solutions and take your semiconductor manufacturing to the next level.

Calm and Soothing Product Description: Motor Shaft Copper Sleeve

Introducing the Motor Shaft Copper Sleeve, a high-quality precision component designed to enhance the performance of your machinery. Crafted with utmost care and expertise by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a reliable machining supplier in the semiconductor industry.

Our Motor Shaft Copper Sleeve is made from H59 brass, a material known for its exceptional durability and reliability. Through precision CNC turning and 5-axis CNC milling, we ensure the utmost accuracy and precision in every detail of this component.

To further enhance its longevity and aesthetics, the Motor Shaft Copper Sleeve undergoes a meticulous electroplating process for surface treatment. This not only adds a touch of elegance but also provides an extra layer of protection against wear and tear.

With its impeccable craftsmanship and advanced machining technology, our Motor Shaft Copper Sleeve is the perfect choice for semiconductor vibration plates, cam machining parts, pulling wheels, carrier pin wheels, ratchets, and more. Its compatibility with various machinery makes it a versatile solution for your machining needs.

Experience the difference of our Motor Shaft Copper Sleeve and elevate the performance of your machinery. Trust in the expertise of HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. to deliver high-quality machining parts that meet your exact specifications.

Robot accessory bracket: Made of AL6061 aluminum alloy through 5-axis milling and natural surface treatment.

Calm and Soothing Fine-Tuning Dial for Terminal Machines and Mechanical Equipment

Introducing our high-quality fine-tuning dial, designed to bring precision and durability to your terminal machines and mechanical equipment. Made from carbon steel with exceptional hardness, this dial has undergone meticulous processing using CNC lathe and precision 5-axis CNC technology. To ensure longevity, the surface has been electroplated for added protection.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we specialize in providing top-notch machining parts for various industries. Our Cam Machining Parts for Semiconductor Vibration Plate are meticulously crafted to meet the demanding requirements of the semiconductor industry.

Key Features:

- Alloy steel construction for enhanced strength and reliability

- Precision machining using advanced 5-axis CNC technology

- Customizable CNC parts to suit your specific needs

- Perfect for semiconductor manufacturing and vibration plate components

With our fine-tuning dial, you can easily adjust the scale of your terminal machines and mechanical equipment, ensuring optimal performance and efficiency. Whether you need to fine-tune a pulling wheel, carrier pin wheel, or ratchet, our dial is the perfect solution.

Trust in our reliable machining services and benefit from our expertise in the semiconductor industry. Our Cam Machining Parts are designed to deliver exceptional performance and longevity, making them the ideal choice for your machining needs.

Calm and Soothing Speech Microphone

Experience the tranquility of our Speech Microphone, crafted with precision using AL6063 aluminum alloy material. Through the meticulous process of CNC lathe and 5-axis CNC, this microphone is transformed into a masterpiece. Its surface is delicately oxidized with a luxurious gold finish, adding a touch of elegance to any setting.

Designed for various public places, our Speech Microphone is perfect for KTV, schools, karaoke halls, stages, and speeches. Its exceptional quality ensures crystal-clear sound transmission, allowing your voice to resonate effortlessly. Whether you’re addressing a crowd or performing on stage, our microphone guarantees a calm and soothing experience for both you and your audience.

Trust in the expertise of HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a reliable machining supplier in the semiconductor industry. Our Cam Machining Parts for Semiconductor Vibration Plate are meticulously crafted using advanced machining technology. With precision cam components and high-quality machining parts, our solutions cater to the specific needs of the semiconductor manufacturing process.

Key Features:

- Alloy steel construction for durability and longevity

- Five-axis machining for precise performance

- Custom CNC parts tailored to your requirements

- Reliable and efficient machining services

Enhance your semiconductor vibration plate with our Cam Machining Parts. From pulling wheels to carrier pin wheels and ratchets, our machining accessories are designed to optimize the performance of your equipment. Experience the seamless integration of our steel ratchet wheel and precision cam components, ensuring smooth operation and increased productivity.

Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for all your machining needs in the semiconductor industry. Our commitment to delivering high-quality machining parts and exceptional customer service sets us apart. Trust in our expertise and let us provide you with reliable solutions that exceed your expectations.

Titanium Alloy Interface

Experience the exceptional quality and precision of our Titanium Alloy Interface. Crafted from Tc4 titanium alloy material using state-of-the-art CNC processing techniques, this interface is perfect for a wide range of applications including equipment interfaces, mechanical interfaces, and aviation plug interfaces.

Company Profile

About Us

Welcome to HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a renowned manufacturer with over 20 years of industry and trade expertise. Located in HangZhou City, ZheJiang Province, China, we pride ourselves on our advanced high-end professional production and processing technology. Our dedicated team of technical management personnel, experienced designers, and R&D experts work tirelessly to deliver innovative solutions. With a perfect company management system in place, we are committed to providing you with the highest quality products.

CNC Training Parts

Introducing our Cam Machining Parts for Semiconductor Vibration Plate, designed to meet the specific needs of the semiconductor industry. Made from alloy steel and manufactured using advanced five-axis CNC machining technology, these precision parts include pulling wheels, carrier pin wheels, ratchets, and more. Our high-quality machining solutions ensure reliable performance and seamless integration into your semiconductor manufacturing process.

5-axis CNC Workshop

Discover high-quality machining parts and custom CNC solutions for the semiconductor industry. Our advanced machining technology and reliable supplier services ensure precision and efficiency. Explore our range of cam machining parts, including semiconductor vibration plates, pulling wheels, carrier pin wheels, ratchets, and more. Trust in our expertise in alloy steel machining and precision cam components. Choose HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for all your machining needs.

Calm and Soothing Product Description: Cam Machining Parts for Semiconductor Vibration Plate

Introducing our high-quality Cam Machining Parts for Semiconductor Vibration Plate, designed and manufactured by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. With a focus on precision and reliability, our machining parts are perfect for the semiconductor industry.

Our factory, spHangZhou over 2,000 square meters, is equipped with state-of-the-art production equipment, including CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, and die-casting equipment. This allows us to master core processing technologies and deliver exceptional results.

Featuring alloy steel construction, our Cam Machining Parts are built to withstand the demands of the semiconductor manufacturing process. The precision machining ensures optimal performance, while the cam wheel assembly guarantees smooth and efficient operation.

With our advanced machining technology, we offer custom CNC parts tailored to your specific requirements. Whether you need pulling wheels, carrier pin wheels, ratchets, brooch pins, or any other cam machining accessories, we have you covered.

Choose our Cam Machining Parts for Semiconductor Vibration Plate and experience the benefits of reliable machining. Trust in our expertise and let us provide you with high-quality machining solutions for your semiconductor industry needs.

Three-dimensional Imager

Enhance your production process with our high-quality auxiliary production equipment. Our range includes electroplating, anodizing, hard anodizing, and surface treatment equipment. These advanced technologies ensure superior results and impeccable surface finishes.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we prioritize precision and quality. That’s why we offer a complete range of testing equipment to ensure the utmost accuracy in our products. Our sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector, and other conventional testing equipment guarantee the highest standards of quality control.

If you are interested in our products, please don’t hesitate to contact us. We are committed to providing the best price support and quality service to meet your needs.

Welcome to HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., where we specialize in providing high-quality machining parts for the semiconductor industry. Our expertise lies in producing precision cam components, including cam machining parts, pulling wheels, carrier pin wheels, ratchets, and more.

Our Advantages

We take pride in our long-standing partnerships with reputable material suppliers, ensuring that the materials we use are of the highest quality. Whether you require aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, or acrylic, we have you covered. Rest assured that all our materials come with supporting documents for your peace of mind.

When it comes to surface treatment, our experienced suppliers are well-versed in meeting the stringent quality requirements. From heat treatment to spray painting, powder coating to plating, we offer a wide range of options to suit your specific needs. Our surface treatment processes include aluminum alloy surface oxidation, ensuring a durable and visually appealing finish.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we understand the importance of precision and reliability in the semiconductor industry. That’s why we utilize advanced machining technology and employ a five-axis machining approach to deliver exceptional results. Our CNC parts are custom-made to meet your exact specifications, guaranteeing a perfect fit and optimal performance.

Choose us as your reliable machining supplier, and experience the benefits of our high-quality machining parts. Whether you need components for vibration plates or cam machining accessories, we have the solutions you’re looking for. Trust in our expertise in the semiconductor manufacturing industry, and let us provide you with top-notch machining services.

Discover the difference that our alloy steel machining can make in your operations. Our precision cam components and steel ratchet wheels are designed to withstand the demands of the semiconductor industry, ensuring long-lasting performance and reliability.

Contact us today to discuss your requirements. We welcome your pictures and letters, and we look CHINAMFG to establishing a good and long-term cooperation with you. Thank you for considering HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. as your trusted partner in precision machining.

HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. offers high-quality dust-free electroless nickel plating on carbon steel surfaces. Perfect for semiconductor vibration plates, our precision machining parts, including cam machining accessories and steel ratchet wheels, are the ideal solution for the semiconductor industry. Trust our reliable machining services and advanced technology for all your machining needs.

FAQ

Product Description: Cam Machining Parts for Semiconductor Vibration Plate

Our Cam Machining Parts for Semiconductor Vibration Plate are precision-engineered components designed to enhance the performance and reliability of semiconductor vibration plates. Made from high-quality alloy steel, these parts are meticulously machined using advanced CNC technology and five-axis machining techniques.

With our expertise in the semiconductor industry, we understand the critical role that vibration plates play in ensuring smooth and efficient operations. Our Cam Machining Parts, including pulling wheels, carrier pin wheels, ratchets, and brooch pins, are specifically designed to meet the demanding requirements of the semiconductor manufacturing process.

By utilizing our custom CNC parts, you can optimize the performance of your vibration plates, resulting in improved productivity and reduced downtime. The precision cam components and steel ratchet wheels ensure smooth and precise movements, allowing for accurate positioning and reliable operation.

At HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., we take pride in our commitment to delivering high-quality machining parts. Our experienced engineers and skilled workforce, along with our state-of-the-art workshop, ensure that every component meets the highest standards of quality and precision.

When you choose our Cam Machining Parts, you can expect exceptional craftsmanship, reliable performance, and long-lasting durability. We prioritize customer satisfaction and strive to exceed your expectations with our reliable machining solutions.

Whether you need machining services for semiconductor vibration plate components or any other precision machining requirements, we are your trusted supplier. Rest assured that your product drawings and specifications will be kept confidential, and we will provide regular updates on the production progress, including detailed schedules, digital pictures, and videos.

Experience the difference of working with a reliable machining supplier. Contact HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. today to discuss your specific needs and discover how our Cam Machining Parts can enhance the performance of your semiconductor vibration plates.

Packaging & Shipping

Calm and Soothing Tone: Cam Machining Parts for Semiconductor Vibration Plate

Experience the highest quality machining parts with our Cam Machining Parts for Semiconductor Vibration Plate. Designed and manufactured by HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd., a reliable machining supplier in the semiconductor industry, these precision cam components are perfect for your semiconductor manufacturing needs.

Our Cam Machining Parts are made from alloy steel, ensuring durability and long-lasting performance. With advanced machining technology and five-axis machining capabilities, we guarantee precise and accurate results every time.

Featuring a ratchet wheel, pulling wheel, carrier pin wheel, and brooch pin, our Cam Machining Parts provide exceptional functionality and reliability. They are designed to optimize the performance of your vibration plate, ensuring smooth and efficient operation.

Whether you need custom CNC parts or cam machining solutions, our machining services have got you covered. We offer a wide range of packaging options to suit your requirements, including commercial packaging and industrial packaging.

Trust HangZhou Xihu (West Lake) Dis.an Hardware Technology Co., Ltd. for all your machining needs. Contact us today to learn more about our Cam Machining Parts for Semiconductor Vibration Plate and how they can enhance your semiconductor manufacturing process.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Professional Service |

|---|---|

| Warranty: | 30 Days |

| Certification: | ISO9001, ISO, CE |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can ratchet wheels be customized for specific uses or integrated into different systems?

Yes, ratchet wheels can be customized for specific uses and seamlessly integrated into various mechanical systems. Customization allows for tailoring ratchet wheels to meet the unique requirements of specific applications. Here are ways in which ratchet wheels can be customized and integrated:

- 1. Custom Tooth Profile: Ratchet wheels can be designed with a specific tooth profile to match the desired level of control and movement. Custom tooth spacing and sizes can be created to achieve precise incremental motion or accommodate varying load capacities.

- 2. Material Selection: Depending on the application’s demands, ratchet wheels can be manufactured from different materials, including various types of metals such as steel, stainless steel, or alloys. Specialized coatings can also be applied for enhanced durability and corrosion resistance.

- 3. Size and Diameter: The size and diameter of the ratchet wheel can be customized to fit within the available space of the mechanical system. This ensures a proper fit without clearance issues or interference with other components.

- 4. Load Capacity: Custom ratchet wheels can be designed to handle specific load capacities, making them suitable for both light-duty and heavy-duty applications. Reinforced designs with larger teeth and diameters can support heavier loads.

- 5. Pawl and Catch Mechanism: The design of the pawl or catch mechanism can be tailored to ensure optimal engagement and disengagement with the custom ratchet wheel. This customization ensures reliable operation in the intended application.

- 6. Precision Requirements: For applications demanding precise control and adjustments, fine-tooth custom ratchet wheels can be created to provide finer incremental movement and enhanced accuracy.

- 7. Regulatory Compliance: Custom ratchet wheels can be designed to meet specific industry standards and safety regulations, ensuring compliance with applicable requirements.

- 8. Integration into Systems: Ratchet wheels can be seamlessly integrated into various systems, including hand tools, winches, tie-down mechanisms, conveyor systems, and more. Their unidirectional and locking capabilities make them valuable components in many applications.

Customized ratchet wheels are often used in specialized industries and applications where standard off-the-shelf components may not fully meet the unique demands. Manufacturers and engineers work closely to design and produce custom ratchet wheels that precisely match the specifications and requirements of the intended use, contributing to the efficiency and reliability of the mechanical systems they are part of.

What safety considerations should be taken into account when using ratchet wheels in various settings?

When using ratchet wheels in various settings, it is crucial to prioritize safety to prevent accidents and ensure the well-being of operators. Here are essential safety considerations to keep in mind:

- 1. Proper Installation and Alignment: Ensure that ratchet wheels are correctly installed and aligned with their accompanying pawls or catches. Misalignment or improper installation can lead to unreliable operation and safety hazards.

- 2. Regular Inspection and Maintenance: Implement a routine inspection and maintenance schedule for ratchet wheels and their associated components. Look for signs of wear, damage, or misalignment, and address issues promptly to prevent accidents.

- 3. Load Capacity: Adhere to the specified load capacity of the ratchet wheel and the entire system. Overloading can cause failures, leading to dangerous situations. Always consider the maximum load when selecting and using ratchet wheels.

- 4. Operator Training: Ensure that operators are adequately trained in the safe use of ratchet wheel systems. Training should cover proper operation, load limits, and safety procedures in case of emergencies.

- 5. Emergency Stop Mechanisms: In applications where ratchet wheels are used as safety interlocks or emergency stop devices, ensure that these mechanisms are reliable and regularly tested. In emergencies, they should halt operations immediately and effectively.

- 6. Lockout/Tagout Procedures: Develop and implement lockout/tagout procedures when working on equipment that includes ratchet wheels. This ensures that machinery is de-energized and cannot be inadvertently started during maintenance or repair activities.

- 7. PPE (Personal Protective Equipment): Provide and require the use of appropriate personal protective equipment, such as gloves and safety glasses, when working with or near ratchet wheel systems. PPE can reduce the risk of injuries in case of accidents.

- 8. Hazard Identification: Identify potential hazards associated with the use of ratchet wheels, including pinch points, sharp edges, and moving parts. Implement guards and warning signs to minimize risks.

- 9. Environmental Conditions: Consider the environmental conditions in which ratchet wheels are used. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized equipment and safety precautions.

- 10. Regular Testing and Certification: Periodically test and certify the safety mechanisms and components associated with ratchet wheels. This ensures that they meet industry standards and function as intended.

- 11. Risk Assessment: Conduct a risk assessment specific to the application of ratchet wheels. Identify potential risks and implement control measures to mitigate them effectively.

- 12. Compliance with Regulations: Be aware of and comply with relevant safety regulations, standards, and guidelines specific to your industry or region. Non-compliance can lead to legal and safety issues.

- 13. Emergency Response Plan: Develop an emergency response plan that outlines procedures for dealing with accidents or malfunctions involving ratchet wheel systems. Ensure that all personnel are familiar with this plan.

By incorporating these safety considerations into the use of ratchet wheels, you can help minimize risks, protect personnel, and ensure a safer working environment across various settings.

Can you explain the primary purpose and applications of ratchet wheels in various industries?

Ratchet wheels serve a primary purpose in various industries by enabling unidirectional motion, preventing backward movement, and offering precise control. Their applications are diverse and include the following:

- 1. Automotive Industry: Ratchet wheels are integral to automotive applications, such as handbrakes and vehicle jacks. Handbrakes use ratchet mechanisms to securely hold a vehicle in place, preventing it from rolling when parked on an incline. Vehicle jacks employ ratchet mechanisms for controlled lifting and lowering of vehicles during maintenance or tire changes.

- 2. Construction and Engineering: Construction and engineering equipment often feature ratchet mechanisms. Ratchet straps and tie-downs are used for securing loads on trucks and trailers. Additionally, ratchet wrenches and torque wrenches provide precise control in construction and assembly tasks, allowing for incremental tightening or loosening of bolts and fasteners.

- 3. Manufacturing and Assembly: Ratchet mechanisms are employed in manufacturing and assembly processes where controlled movement is essential. This includes machinery used in factories for precision tasks like fastening, clamping, or incrementally advancing components on an assembly line.

- 4. Medical Devices: The medical industry utilizes ratchet wheels in various instruments and devices. For instance, surgical instruments may feature ratchet mechanisms to control the movement of specific components, allowing surgeons to perform delicate procedures with precision.

- 5. Material Handling: In material handling equipment such as winches, hoists, and cranes, ratchet wheels ensure the controlled lifting and lowering of heavy loads. They contribute to safety and prevent unintended load movement, making them crucial in industries like construction, manufacturing, and logistics.

- 6. Consumer Products: Ratchet mechanisms are found in many consumer products. A common example is a retractable tape measure, where a ratchet wheel allows the tape to be extended and then locked in place at the desired length. Similarly, many hand tools like screwdrivers and pliers feature ratchet mechanisms for efficient and continuous rotation in one direction.

- 7. Aerospace and Aviation: Ratchet wheels are used in aerospace and aviation applications for tasks like securing cargo in aircraft, controlling movements in cockpit instruments, and ensuring the proper operation of various components within the aircraft.

- 8. Marine and Boating: Marine equipment often employs ratchet mechanisms in winches and pulleys for controlling sails, anchors, and other rigging. They enable sailors to adjust sail tension and anchor position with precision.

- 9. Sports and Recreation: Ratchet mechanisms are used in sports and recreational equipment, such as bike gears and fishing reels. They provide controlled motion and prevent backward movement, enhancing the user experience and safety.

Ratchet wheels are versatile components that find applications in an array of industries, improving safety, control, and efficiency across various mechanical systems.

editor by CX 2024-01-05