Product Description

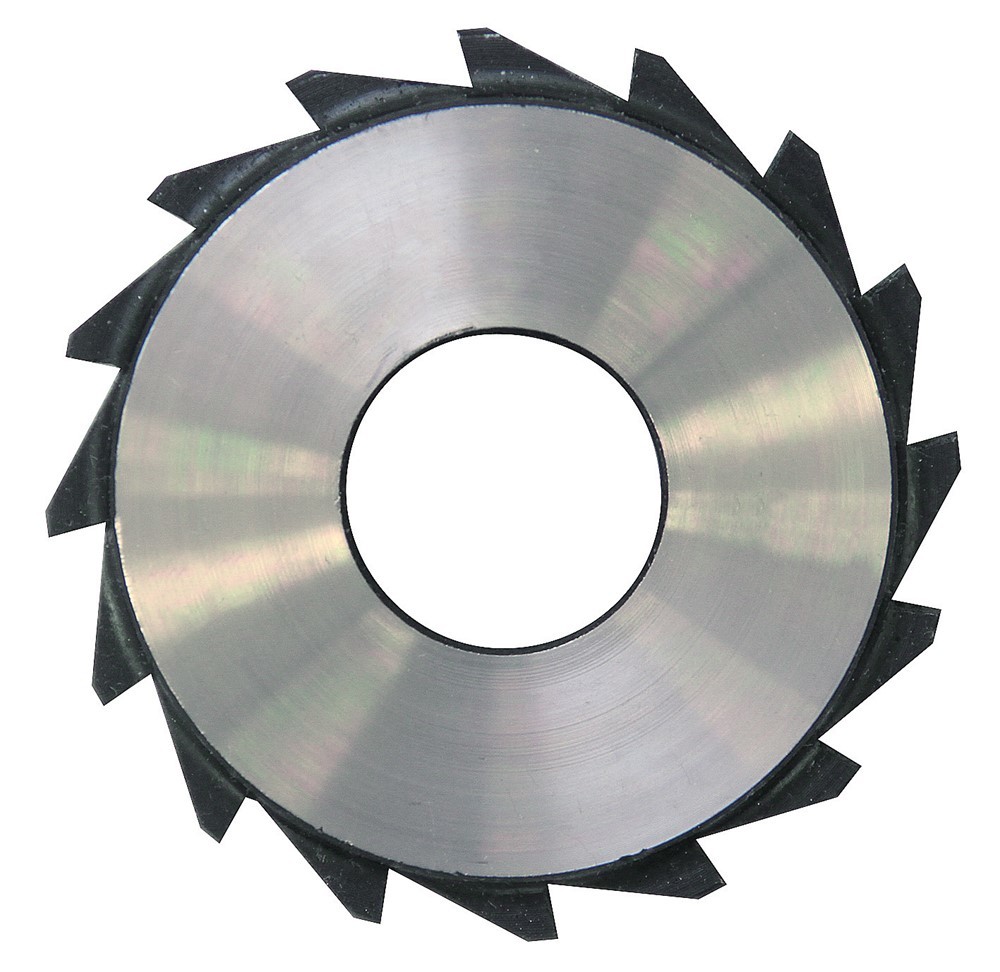

4inch Rubber Erase Wheel Auto Tools for Car Polishing

* PRODUCT PICTURES

* SPECIFICATION

* MORE PRODUCTS

1) 1”~ 6” Air Orbital Sander/Polisher (USA, Europe, Japan, ZheJiang Quality)

2) 2”~9 ” Air Angle Grinder (Japan&ZheJiang Quality)

3) Air Die Grinder (Japan&ZheJiang Quality)

4) Air Micro Grinder / Air Pencil Grinder

5) Air Screwdriver

6) Air Impact Wrench

7) Air Ratchet Wrench

8) Air Belt Sander

9) Air Drawing Machine

10) Air File

11) Air Saw

12) Air Squeezer

13) Air Pull Setter / Air Riveter

14) Air Drill

15) Air Spray Gun

16) Oil Pulse Air Tools

16) Air Squeeze Riveter

17) Air Chipping Hammer

18) Air Carton-Waste Stripper

19) Sanding Backup Pad

20) Sand Paper

21) Grinding Wheel

22) Wool/Sponge/Foam Buffing Pad

23) Mounted Points

24) Riveting Nut, Pop Rivet

25) Car Care Poducts

25) All Tools Spare Parts

Etc…

*WHY CHOOSE US

1. Superior Quality & Competitive Prices

–We’re the first manufacturer in China to make professional-level AIR TOOLS&ABRASIVES. We have enough experience in making quality products with competitive prices.

2. Best Service

–We provide you with the best service. All tools spare parts available for aftersales service and we can teach you how to repair tools with videos or detailed repairing manual in pdf; Technical solution will be given in time if you meet any problem. Short lead time to prepare your orders and let you receive the products ASAP; We are almost 18 hours online every day.

3. Strong QC System

–We have a strong quality-control team to inspect every product and make sure they are 100% perfect before sending to customers.

4. Bright Future Cooperation

–We keep improving, innovating and creating products. So your product range will be widen and widen and more professional. Our strong sales team can teach you how to sell and where sell to.

| Material: | Rubber |

|---|---|

| Pad Diameter: | 4 Inch (100mm) |

| Thickness: | 20mm |

| Max Speed: | 4000rpm |

| Thread: | 5/16′′-24 |

| Transport Package: | Carton Packing |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you explain the impact of ratchet wheels on the overall safety of mechanical systems?

Ratchet wheels play a crucial role in enhancing the overall safety of mechanical systems in various applications. Their impact on safety can be summarized as follows:

- 1. Preventing Unintended Backdriving: One of the primary safety benefits of ratchet wheels is their ability to prevent unintended backdriving or reverse motion. When a pawl or catch mechanism engages with the teeth of the ratchet wheel, it locks the wheel in place, ensuring that the system does not move in the undesired direction. This feature is especially important in applications where maintaining a specific position or preventing sudden movement is critical for safety.

- 2. Controlled Motion: Ratchet wheels provide controlled and incremental motion, allowing users to make precise adjustments or movements. This controlled motion is essential in applications where precise positioning or controlled advancement is necessary for safety reasons, such as in medical devices, manufacturing equipment, or safety mechanisms.

- 3. Safety Interlocks: Ratchet wheels are often used in safety interlock systems where certain conditions must be met for a system to operate safely. For example, in industrial machinery, a ratchet wheel and pawl mechanism can be part of an interlock system that ensures equipment remains stationary until specific safety conditions are met, reducing the risk of accidents.

- 4. Load Handling and Securement: In load handling and securement applications, such as winches and tie-down straps, ratchet wheels help maintain tension and prevent slack. This contributes to the safe transportation of loads, reducing the risk of load shifts or accidents during transit.

- 5. Emergency Stop Systems: Ratchet wheels are employed in emergency stop systems to ensure that once the system is activated, it remains in a safe state until intentionally reset. This safety feature is vital in machinery and equipment where rapid shutdown is necessary to prevent hazards.

- 6. Reliability and Predictability: Ratchet wheels offer reliability and predictability in their operation. Users can apply force or torque in the desired direction with confidence, knowing that the ratchet mechanism will engage and prevent unexpected movement. This predictability enhances the overall safety of the system.

- 7. Versatility in Safety Applications: Ratchet wheels find application in a wide range of safety-critical systems, including vehicle handbrakes, safety gates, medical devices, and more. Their ability to provide controlled and secure motion makes them versatile components in various safety applications.

In summary, ratchet wheels contribute significantly to the safety of mechanical systems by preventing unintended movement, providing controlled motion, enabling safety interlocks, and enhancing reliability. Their presence in safety-critical applications helps reduce the risk of accidents and ensures that systems operate safely and predictably.

How do ratchet wheels contribute to the precision and repeatability of certain applications?

Ratchet wheels play a pivotal role in enhancing precision and repeatability in various applications by providing controlled and incremental motion. Their contributions to precision and repeatability can be explained as follows:

- 1. Controlled Movement: Ratchet wheels are designed to engage with pawls or catches in a way that allows them to move in only one direction while preventing backward movement. This controlled movement ensures that adjustments, increments, or positioning occur with a high degree of accuracy.

- 2. Incremental Adjustments: In applications where precision is crucial, such as in manufacturing, assembly, or calibration equipment, ratchet wheels enable users to make incremental adjustments or movements. This precision allows for fine-tuning and achieving the exact desired outcome.

- 3. Consistency and Repeatability: Ratchet mechanisms, including ratchet wheels, provide a consistent and repeatable motion. Users can reliably achieve the same result repeatedly, ensuring product consistency in manufacturing or consistent positioning in various tasks.

- 4. Safety and Position Locking: Ratchet wheels are commonly used in safety-critical applications where specific positions must be securely locked. This locking feature not only enhances safety but also ensures that a particular setting or position remains precise and repeatable.

- 5. Indexing and Positioning: In applications like indexing tables or machinery requiring precise indexing or positioning, ratchet wheels enable accurate and repeatable alignment of components or workpieces. This is essential for processes such as drilling, milling, or assembly.

- 6. Calibration and Measurement: Ratchet mechanisms are utilized in calibration equipment to allow for precise adjustments of measuring instruments. This contributes to the accuracy and repeatability of measurements, which is critical in scientific, laboratory, and metrology applications.

- 7. Safety Interlocks: Ratchet wheels are often part of safety interlock systems that require specific conditions to be met before certain operations can proceed. This ensures that critical safety protocols are consistently followed.

- 8. Reliability in Emergency Systems: Ratchet mechanisms are incorporated into emergency systems where reliability and repeatability are paramount. For example, emergency stop systems rely on the repeatability of ratchet wheels to ensure consistent and immediate shutdown of machinery.

- 9. Reducing Human Error: In applications where human operators are involved, ratchet wheels help reduce the likelihood of errors. The controlled and incremental motion they provide minimizes the risk of overshooting or undershooting desired settings.

In summary, ratchet wheels contribute to precision and repeatability by enabling controlled and incremental motion, ensuring consistent and repeatable results, and enhancing safety in various applications across industries.

What is a ratchet wheel, and how does it function in mechanical systems?

A ratchet wheel is a mechanical component that plays a crucial role in various systems by allowing unidirectional motion or preventing backward movement. It functions through a simple yet effective mechanism:

A ratchet wheel typically consists of a toothed wheel or gear with angled teeth and a corresponding pawl, which is a small lever or catch. The pawl is mounted or positioned adjacent to the ratchet wheel, and it has a pointed end that engages with the teeth on the wheel.

Here’s how a ratchet wheel functions:

- Unidirectional Motion: When an external force is applied to the system in a particular direction, the pointed end of the pawl engages with the angled teeth on the ratchet wheel. As a result, the wheel rotates freely in the direction of the applied force, allowing unidirectional motion.

- Preventing Backward Movement: However, if an attempt is made to move the system in the opposite direction, the angled teeth on the ratchet wheel lock against the pawl. The pawl prevents the wheel from rotating backward, effectively creating a mechanical “click” or “ratchet” sound and preventing reverse motion.

- Incremental Advancement: In some applications, ratchet wheels are used to provide incremental advancement. Each engagement of the pawl with a tooth on the wheel allows the wheel to move by a fixed amount or angle. This is commonly seen in tools like socket wrenches, where a ratchet mechanism allows for continuous tightening or loosening without needing to reposition the tool.

Ratchet wheels find applications in a wide range of mechanical systems, including:

- Hand Tools: Socket wrenches, screwdrivers, and pliers often feature ratchet mechanisms that enable efficient and continuous rotation in one direction while preventing backward motion.

- Winches and Hoists: Ratchet wheels are used in winches and hoists to control the winding and unwinding of cables or ropes, ensuring that loads can be raised or lowered safely and incrementally.

- Automotive Applications: Ratchet mechanisms are used in car jacks and handbrakes to secure vehicles and prevent unintended movement.

- Medical Devices: Some medical instruments use ratchet mechanisms to control the movement of specific components, ensuring precise and controlled actions.

- Industrial Machinery: Ratchet wheels are found in various industrial machines and equipment where controlled motion in one direction is essential for safety and operation.

In summary, a ratchet wheel is a mechanical device that allows unidirectional motion while preventing backward movement through the engagement of a pawl and angled teeth. Its simple yet effective design makes it a valuable component in numerous mechanical systems across various industries.

editor by CX 2023-12-04