Product Description

Product Description

| Red Plating Aluminium Snap Hook |

Company information

HangZhou CHINAMFG Rigging Co.,Ltd, for many years supplies a range of industrial products that covers lifting, lashing, slings, rigging, marine, ining, towing, transportation, construction,fishing and security applications.

We had exported our products to Europe, America, Africa, New Zealand, and Australia… etc. Our customers cover more than 120 countries and regions worldwide.

Our company’s reputation has been built on Quality, Safety and Service. In all markets safety is critical, and this starts with a quality product backed by a reliable company. All the products are produced under strict standard of quality control, and constant research and development ensuring that you will get the latest products produced with the most advanced and cost effective technologies.

All of our manufacturing factories are ISO 9001 certified. Over the years, our lifting products have established a reputation for quality across the key continents. Our products comply with the various demanding National and International standards. Most of our products are CE certified. Before shipping, we can accept the test by third party, like BV, SGS, etc. To ensure products meet the clients’ requirement. We are confident that our products and service will satisfy the highest standards of requirements.

FAQ

Q1:How to order the products?

Send the inquiry with detail item description or with ITEM number. Tell us the quantity you need, the size of goods, and the packing. If there is no packing demand we take it as seaway packing. If possible please attach one reference picture to avoid any misunderstanding or any links from our website for we get a better understanding.

Q2:About sample:

Cost with free if the quantity small, and the express charge account into buyer’s.

Q3:What products can I supply?

1. Rigging hardware (shackle,turnbuckle, eye bolt & nuts, hook, quick links, swivel & rings, CHINAMFG brass hook & ring)

2. CHINAMFG & G100 rigging(G80 & G100 chain sling, g100 alloy hooks & fittings, CHINAMFG alloy hooks, CHINAMFG alloy links & rings, CHINAMFG & g100 alloy chain, CHINAMFG alloy swivels, bolt& nuts)

3. Synthetic lifting sling & harness(Webbing sling, webbing sling endless type, round sling, webbing net, safety harness & safety belt)

4. Cargo control & Transport products (ratchet tie down,ratchet buckle & end fittings,cargo control product, G70 chain & fittings, load binder,bungee cords & plastic straps, cargo bar & jack bars, shoring bars, cargo lock, plank & decking beam)

5. Chains And Accessories (chain hooks, weldless & weld link chain, special chain)

6. Stainless steel rigging (stainless steel shackles, stainless steel turnbuckles, stainless steel wire rope thimbles, stainless steel wire rope clips, stainless steel hooks, stainless steel swivels,stainless steel rings & links, stainless steel bolts & nuts, stainless steel chains, stainless steel wire rope, stainless steel anchor & fittings,stainless steel fasteners,stainless steel others)

7. Steel wire rope & fittings (steel wire rope, wire rope thimble, ferrules & sleeves, wire rope clip)

8. Manual hoist & lifting equipments(chain hoist, lever hoist, electric chain hoist, electric trolley, electric wire rope hoist, electric winch, wire rope pulling hoist, push & geared travel trolley, beam clamp, lifting clamp, trolley clamp, snatch block, permanent magnetic lifter, crane scale)

9. Marine hardware (anchor, anchor chain, accessories, marine rope)

Q4:How do you receive the goods?

With professional transport agents, we are capable of delivery products to most ports all over the world.

| Material: | Aluminium |

|---|---|

| Type: | Hook |

| Shape: | D Shape |

| Usage: | Industrial, Household |

| Brand: | Yan Fei |

| Condition: | New |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

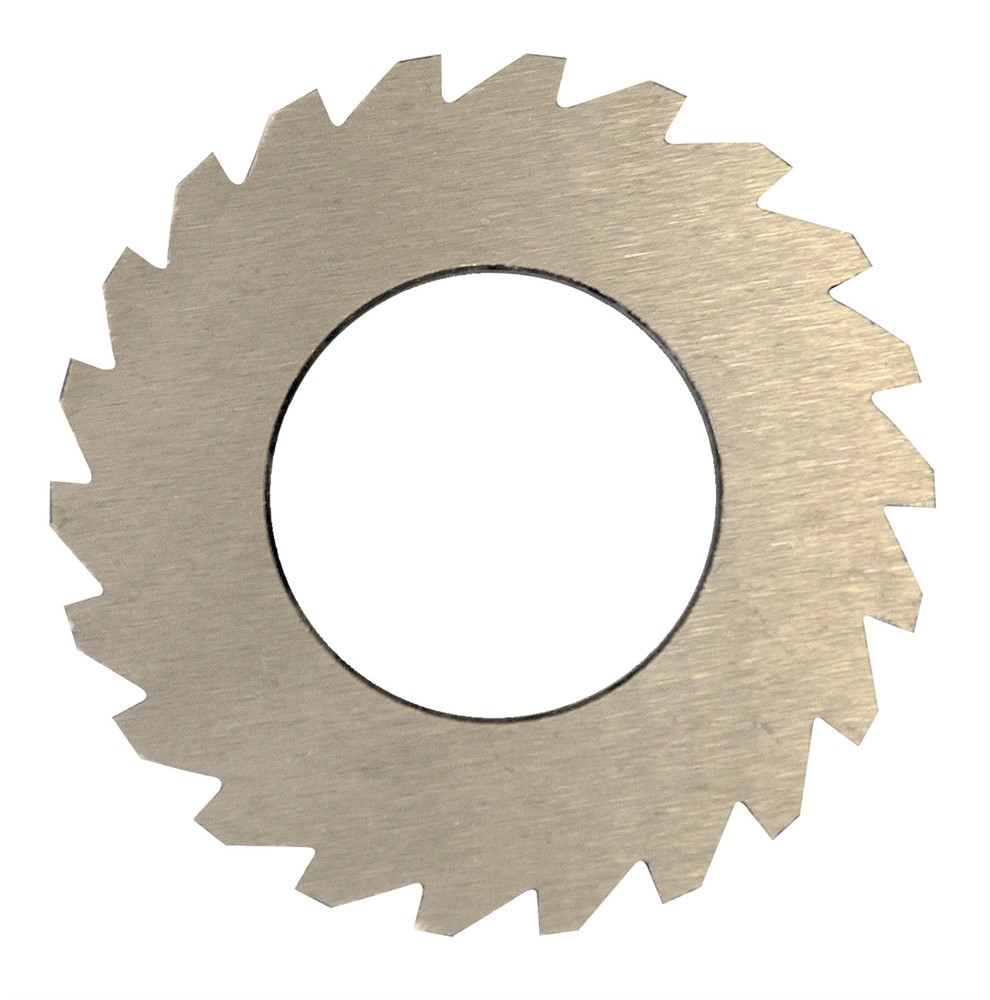

Can you provide examples of machinery or equipment that commonly use ratchet wheels?

Ratchet wheels are commonly used in various machinery and equipment across different industries due to their ability to provide controlled motion and security. Here are examples of machinery and equipment that commonly incorporate ratchet wheels:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, utilize ratchet wheels to enable continuous tightening or loosening of nuts and bolts without the need to remove and reposition the wrench. The unidirectional motion of the ratchet wheel allows for efficient and convenient use.

- 2. Winches and Hoists: Winches and hoists, whether manual or powered, frequently employ ratchet wheels in their mechanisms. Ratchet wheels ensure controlled lifting, lowering, or pulling of loads while preventing unintended backdriving.

- 3. Handbrakes in Vehicles: Many vehicles, especially older models, feature handbrake systems that rely on ratchet wheels. These ratchet mechanisms secure the vehicle’s position when the handbrake lever is engaged, preventing the vehicle from rolling.

- 4. Tie-Down Straps: Ratchet mechanisms are integral components of tie-down straps used for securing cargo during transportation. They maintain tension in the strap and prevent slack, ensuring that the load remains securely fastened.

- 5. Conveyor Systems: Conveyor systems in manufacturing and logistics often incorporate ratchet wheels to control the movement of items along the conveyor belts. Ratchet wheels enable precise indexing and positioning of products.

- 6. Scaffold Systems: Scaffold systems used in construction frequently feature ratchet wheels in their height adjustment mechanisms. Workers can raise or lower scaffolding platforms incrementally, ensuring safety and stability.

- 7. Fishing Reels: Fishing reels, such as baitcasting and trolling reels, use ratchet wheels in their drag systems. This allows anglers to smoothly reel in fish while preventing the fish from pulling out line unintentionally.

- 8. Safety Mechanisms: Various safety mechanisms and emergency stop systems employ ratchet wheels to ensure that once activated, the system remains in a safe state until intentionally reset. This is crucial in industrial and machinery safety applications.

These examples demonstrate the versatility of ratchet wheels in different industries and applications where controlled motion, security, and prevention of reverse movement are essential requirements.

What safety considerations should be taken into account when using ratchet wheels in various settings?

When using ratchet wheels in various settings, it is crucial to prioritize safety to prevent accidents and ensure the well-being of operators. Here are essential safety considerations to keep in mind:

- 1. Proper Installation and Alignment: Ensure that ratchet wheels are correctly installed and aligned with their accompanying pawls or catches. Misalignment or improper installation can lead to unreliable operation and safety hazards.

- 2. Regular Inspection and Maintenance: Implement a routine inspection and maintenance schedule for ratchet wheels and their associated components. Look for signs of wear, damage, or misalignment, and address issues promptly to prevent accidents.

- 3. Load Capacity: Adhere to the specified load capacity of the ratchet wheel and the entire system. Overloading can cause failures, leading to dangerous situations. Always consider the maximum load when selecting and using ratchet wheels.

- 4. Operator Training: Ensure that operators are adequately trained in the safe use of ratchet wheel systems. Training should cover proper operation, load limits, and safety procedures in case of emergencies.

- 5. Emergency Stop Mechanisms: In applications where ratchet wheels are used as safety interlocks or emergency stop devices, ensure that these mechanisms are reliable and regularly tested. In emergencies, they should halt operations immediately and effectively.

- 6. Lockout/Tagout Procedures: Develop and implement lockout/tagout procedures when working on equipment that includes ratchet wheels. This ensures that machinery is de-energized and cannot be inadvertently started during maintenance or repair activities.

- 7. PPE (Personal Protective Equipment): Provide and require the use of appropriate personal protective equipment, such as gloves and safety glasses, when working with or near ratchet wheel systems. PPE can reduce the risk of injuries in case of accidents.

- 8. Hazard Identification: Identify potential hazards associated with the use of ratchet wheels, including pinch points, sharp edges, and moving parts. Implement guards and warning signs to minimize risks.

- 9. Environmental Conditions: Consider the environmental conditions in which ratchet wheels are used. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized equipment and safety precautions.

- 10. Regular Testing and Certification: Periodically test and certify the safety mechanisms and components associated with ratchet wheels. This ensures that they meet industry standards and function as intended.

- 11. Risk Assessment: Conduct a risk assessment specific to the application of ratchet wheels. Identify potential risks and implement control measures to mitigate them effectively.

- 12. Compliance with Regulations: Be aware of and comply with relevant safety regulations, standards, and guidelines specific to your industry or region. Non-compliance can lead to legal and safety issues.

- 13. Emergency Response Plan: Develop an emergency response plan that outlines procedures for dealing with accidents or malfunctions involving ratchet wheel systems. Ensure that all personnel are familiar with this plan.

By incorporating these safety considerations into the use of ratchet wheels, you can help minimize risks, protect personnel, and ensure a safer working environment across various settings.

Can you describe the factors to consider when selecting ratchet wheels for specific applications?

When selecting ratchet wheels for specific applications, several important factors should be taken into consideration to ensure optimal performance and reliability. These factors include:

- 1. Load Capacity: Determine the maximum load or force the ratchet wheel will need to handle. Choose a ratchet wheel with the appropriate load capacity to ensure safe and efficient operation. Larger and more robust ratchet wheels are suitable for heavy-duty applications.

- 2. Space Constraints: Consider the available space within the mechanical system where the ratchet wheel will be installed. Ensure that the selected ratchet wheel size fits within the allocated space without interference or clearance issues.

- 3. Tooth Profile: The tooth profile of the ratchet wheel should match the application’s requirements. Standard ratchet wheels have angled teeth, while fine-tooth ratchet wheels offer finer control. Select the tooth profile that suits the desired level of precision and movement control.

- 4. Material: Choose a ratchet wheel material that is compatible with the application’s environment and demands. Common materials include hardened steel or alloy metals for durability. In corrosive environments, opt for corrosion-resistant coatings or materials.

- 5. Pawl Compatibility: Ensure that the selected ratchet wheel is compatible with the pawl or catch mechanism used in the application. The pawl should effectively engage and disengage with the ratchet wheel’s teeth for reliable operation.

- 6. Precision Requirements: Consider the level of precision required in the application. Fine-tooth ratchet wheels are suitable for applications demanding precise adjustments, while standard ratchet wheels offer a balance of control and strength.

- 7. Operating Conditions: Evaluate the operating conditions, including temperature extremes, humidity, and exposure to chemicals or contaminants. Select ratchet wheels that can withstand these conditions without degradation.

- 8. Customization: For specialized applications or unique requirements, consider the option of custom-designed ratchet wheels. Customization allows for tailoring the ratchet wheel’s size, tooth profile, and material to meet specific needs.

- 9. Maintenance: Assess the ease of maintenance and lubrication requirements. Some ratchet wheels may need periodic cleaning and lubrication to ensure smooth and reliable operation.

- 10. Regulatory Compliance: In some industries, specific standards and regulations may govern the choice of components. Ensure that the selected ratchet wheel complies with relevant industry standards and safety regulations.

By carefully considering these factors, you can select the most suitable ratchet wheel for your specific application, promoting efficient and reliable performance while minimizing the risk of issues or failures.

editor by CX 2023-11-28