Product Description

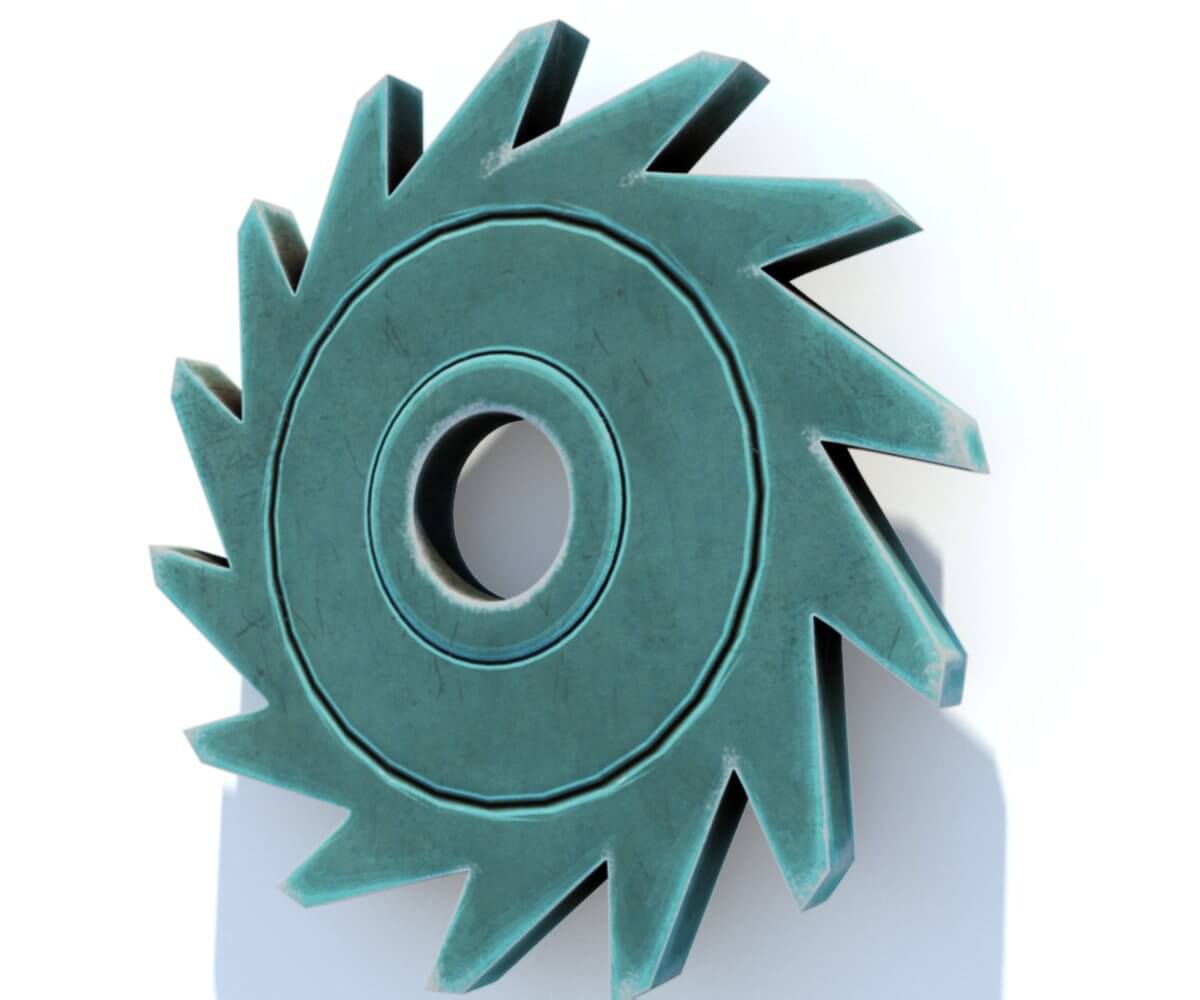

CNC Machining POM Derlin ABS PA Nylon Plastic Ratchet Gear/Sun Ring Reverse Printer Gear

Product Details

Products Type

We can custom shape,size,color material and quantity for plastic gear as your requirment.

Products Specification

1. Various hardness for your choice.

2. Good abrasion, heat and oil resistance.

3. Good anti-aging performance and gas tightness.

4. Ease of bonding to other material.

5. Excellent oxygen and CHINAMFG resistance.

6. Non-flammable,self-extinguish.

| Material | PA,PA6,PA66,PP,PE,LDPE,HDPE,UWHDPE,PTFE,POM,ABS,or Custom Compound (Any custom compound plastic is available) |

| Size | According to samples or drawings |

| Color | Black,white,red,green,transparent or any color according to Pantone colors |

| Finish | High Gloss,Fine Grain,Electroplating,Painting,Printing,Texture etc,or as request |

| Type | Round,square,rectangular,or any nonstandard shape as request |

| Logo | Debossed,embossed,printed logo or as request |

Our Factory

Customization Capabilities

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Industry |

|---|---|

| Hardness: | Hardened |

| Gear Position: | Internal and External |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What maintenance practices are recommended for ratchet wheels to ensure optimal functionality?

Maintaining ratchet wheels is essential to ensure their optimal functionality and longevity in mechanical systems. Here are recommended maintenance practices for ratchet wheels:

- 1. Regular Inspection: Perform routine visual inspections of the ratchet wheel and the surrounding components. Look for signs of wear, damage, or deformation. Pay attention to the teeth, as worn or damaged teeth can affect engagement.

- 2. Cleaning: Keep the ratchet wheel and associated components clean from dirt, debris, and contaminants. Clean with a suitable solvent or degreaser to remove built-up grime and ensure smooth operation.

- 3. Lubrication: Apply a suitable lubricant to the ratchet wheel and pawl or catch mechanism to reduce friction and prevent premature wear. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

- 4. Pawl or Catch Inspection: Check the pawl or catch mechanism that engages with the ratchet wheel. Ensure it is in good condition, and there is no excessive wear or damage. Replace worn or damaged pawls promptly.

- 5. Alignment: Verify that the ratchet wheel is correctly aligned with the pawl or catch. Misalignment can lead to uneven wear and reduced effectiveness. Make any necessary adjustments to ensure proper engagement.

- 6. Tightening Fasteners: Periodically check and tighten any fasteners, such as bolts and nuts, that secure the ratchet wheel and its associated components. Loose fasteners can lead to play and affect performance.

- 7. Teeth Replacement: If teeth on the ratchet wheel show signs of significant wear or damage, consider replacing the ratchet wheel or the affected teeth. Damaged teeth can lead to unreliable engagement.

- 8. Corrosion Prevention: In corrosive environments, take measures to prevent rust or corrosion on the ratchet wheel. This may include applying protective coatings or using corrosion-resistant materials.

- 9. Calibration (If Applicable): In applications requiring precise control, consider calibrating the ratchet wheel to ensure it provides the desired incremental movement accurately.

- 10. Safety Check: Ensure that ratchet wheels in safety-critical applications are functioning correctly and have not been compromised in any way. This includes systems in vehicles, safety equipment, and emergency mechanisms.

- 11. Replacement: As ratchet wheels age and show significant wear, it’s advisable to replace them to maintain the reliability and safety of the system.

Regular maintenance and inspection of ratchet wheels are essential to prevent unexpected failures, ensure proper engagement, and extend their service life. Following these maintenance practices helps maintain the optimal functionality and reliability of ratchet wheels in mechanical systems.

How does the choice of ratchet wheels affect the overall performance and reliability of mechanical systems?

The choice of ratchet wheels plays a significant role in determining the overall performance and reliability of mechanical systems. Here’s how different factors related to ratchet wheel selection impact these aspects:

- 1. Load Capacity: The load capacity of the chosen ratchet wheel must match the intended application. Using a ratchet wheel with insufficient load capacity can lead to premature wear, slippage, and safety risks.

- 2. Material Selection: Ratchet wheels are available in various materials, such as steel, stainless steel, and plastic. The choice of material affects factors like durability, corrosion resistance, and weight. Selecting the appropriate material for the environment and application is critical.

- 3. Tooth Profile and Design: The tooth profile and design of the ratchet wheel impact how well it engages with the pawl or catch. Proper tooth design ensures reliable engagement, reducing the risk of slippage or unintended movement.

- 4. Precision and Tolerance: High-precision ratchet wheels with tight tolerances provide smoother and more consistent operation. Precision is essential in applications where accuracy and repeatability are critical.

- 5. Pawl Compatibility: Ensure that the selected ratchet wheel is compatible with the accompanying pawl or catch mechanism. Incompatibility can lead to issues with engagement and reliability.

- 6. Surface Finish: The surface finish of the ratchet wheel affects friction and wear. A polished or treated surface can reduce friction, extend the service life, and enhance performance.

- 7. Environmental Considerations: Consider the environmental conditions in which the ratchet wheel will operate. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized materials or coatings to maintain reliability.

- 8. Maintenance Requirements: Some ratchet wheels may require more frequent maintenance than others. Understanding the maintenance needs of the chosen ratchet wheel is crucial for long-term reliability.

- 9. Compliance with Standards: Ensure that the selected ratchet wheel complies with industry standards and regulations. Compliance is essential for safety and reliability in specific applications.

- 10. Cost-Benefit Analysis: Consider the cost-effectiveness of the chosen ratchet wheel. While high-quality options may come at a higher price, they often offer better long-term reliability and reduced maintenance costs.

- 11. Application-Specific Features: Some ratchet wheels may offer features tailored to specific applications, such as noise reduction or enhanced security. Choosing a wheel with the right features can improve overall system performance.

- 12. Supplier Reputation: The reputation and reliability of the supplier or manufacturer also play a role. Established suppliers with a track record of quality can offer assurance in the performance of their products.

In summary, the choice of ratchet wheels affects the overall performance and reliability of mechanical systems by influencing load capacity, material selection, tooth design, precision, and many other factors. Selecting the right ratchet wheel for a given application is crucial for achieving optimal system performance and longevity.

Can you describe the factors to consider when selecting ratchet wheels for specific applications?

When selecting ratchet wheels for specific applications, several important factors should be taken into consideration to ensure optimal performance and reliability. These factors include:

- 1. Load Capacity: Determine the maximum load or force the ratchet wheel will need to handle. Choose a ratchet wheel with the appropriate load capacity to ensure safe and efficient operation. Larger and more robust ratchet wheels are suitable for heavy-duty applications.

- 2. Space Constraints: Consider the available space within the mechanical system where the ratchet wheel will be installed. Ensure that the selected ratchet wheel size fits within the allocated space without interference or clearance issues.

- 3. Tooth Profile: The tooth profile of the ratchet wheel should match the application’s requirements. Standard ratchet wheels have angled teeth, while fine-tooth ratchet wheels offer finer control. Select the tooth profile that suits the desired level of precision and movement control.

- 4. Material: Choose a ratchet wheel material that is compatible with the application’s environment and demands. Common materials include hardened steel or alloy metals for durability. In corrosive environments, opt for corrosion-resistant coatings or materials.

- 5. Pawl Compatibility: Ensure that the selected ratchet wheel is compatible with the pawl or catch mechanism used in the application. The pawl should effectively engage and disengage with the ratchet wheel’s teeth for reliable operation.

- 6. Precision Requirements: Consider the level of precision required in the application. Fine-tooth ratchet wheels are suitable for applications demanding precise adjustments, while standard ratchet wheels offer a balance of control and strength.

- 7. Operating Conditions: Evaluate the operating conditions, including temperature extremes, humidity, and exposure to chemicals or contaminants. Select ratchet wheels that can withstand these conditions without degradation.

- 8. Customization: For specialized applications or unique requirements, consider the option of custom-designed ratchet wheels. Customization allows for tailoring the ratchet wheel’s size, tooth profile, and material to meet specific needs.

- 9. Maintenance: Assess the ease of maintenance and lubrication requirements. Some ratchet wheels may need periodic cleaning and lubrication to ensure smooth and reliable operation.

- 10. Regulatory Compliance: In some industries, specific standards and regulations may govern the choice of components. Ensure that the selected ratchet wheel complies with relevant industry standards and safety regulations.

By carefully considering these factors, you can select the most suitable ratchet wheel for your specific application, promoting efficient and reliable performance while minimizing the risk of issues or failures.

editor by Dream 2024-04-29

CNC made in China – replacement parts – in Lubumbashi Democratic Republic of the Congo Machining High Precision Gears with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 various branches. For much more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

CNC machining substantial precision gears

| Description: | gears |

| Primary equipments | More than a hundred and twenty sets machining equipments, and superior inspection tools |

| Material capability | one.Carbon metal, alloy steel, stainless metal two.Aluminum alloy, brass, bronze 3.Grey iron, ductile iron four.Plastic: stomach muscles, pp, pa, and so forth |

| Primary procedures | Machining, Forging, Casting, Welding, Bending, Stamping, Injection |

| Surface remedy | Zinc plate, chrome plate, polishing, paint, powder coat, shot blast, sand blast, phosphating, grinding |

| Primary advantages | one.Maker with set up supply associates two.A single-stop support to make your sourcing straightforward 3.Potent specialized ability four.Expert and affordable pricing five.a hundred%good quality guarantee: incoming inspection, 100% important dimension check, tour verify, spot check out, physical appearance inspection at packing 6.Very easy to deal with and aim to set up prolonged-time period and increasing business |

| Service | OEM, ODM, Assembly, and many others |

| Delivery phrase | FOB, CIF, CFR and so on |

| Guide time | In-time, photographs for actual status |

| Payment term | Typically, 30%deposit 70% when areas are ready Negotiable |

Processing:

More EPT products

EPT components items:

Business Information

Jingdian Technological innovation Co., Ltd. is a solution supplier who provides steel hardware equipment for the fields from building, electromechanical, automotive, railway, agricultural machinery, furnishings and engineering machinery and so forth..

Besides, we integrates the design, manufacturing, research and development of the bracing products – support and hanger for the construction subject, and the provider this sort of as the extensive optimization of BIM pipeline and relevant supporting service. Principal scope: Gravity Bracket, Anti-fall Bracket, Anti-seismic Bracket, Pipeline Bracket, Fasteners and relevant equipment etc..

Jingdian Engineering holds the principle of ” Quality Very first, Services Priority”, we expect to meet with you the esteemed clients from all in excess of the entire world, we will offer high high quality product and excessive support!

Product Certificate

The use of authentic gear manufacturer’s (OEM) portion quantities or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our company and the outlined substitution elements contained herein are not sponsored, authorized, or created by the OEM.

Best China manufacturer & factory High in Fort Worth United States precision oem customized professional cnc brass machining two wheeler engine parts With high quality best price

In 2008, it was awarded with “National Export Commodity Inspection-free of charge Company”.

Overview

Quick Specifics

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Provider:

-

Help

- Tolerance:

-

.01-.05mm or Custom-made

- Certification:

-

ISO9001, SGS

Most generally, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be run immediately by the engine.

- Surface area Treatment method:

-

Sandblasting,Sharpening,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric powered Equipment,Hardware,and so on.

RV025~RV150 Solid Shaft Enter RV025~RV150 Attributes: 1. Good quality aluminum alloy gear box, light bodyweight and not rust 2. 2 optional worm wheel resources: Tin (Stannum) bronze or aluminum bronze alloy 3. Common areas and really flexible for shaft configurations and motor flange interface 4. Numerous optional mounting alternatives 5. Low sounds, Higher performance in warmth dissipation

- Dimension:

-

As Customers’ Ask for

- Equipment:

-

Milling/Lathe/Drilling/4/3 Axis CNC Machining Centre

- Drawing Format:

-

Pro/E, Car CAD, Reliable Performs,IGS,UG, CAD/CAM/CAE

Provide Capacity

- Offer Ability:

- 10000 Piece/Parts for each Thirty day period

Packaging & Shipping and delivery

- Port

- nb

-

Lead Time

: -

Quantity(Pieces) one – five hundred >500 Est. Time(times) thirty To be negotiated

On-line Customization

Higher precision oem customized skilled cnc brass machining two wheeler motor components

Item Description

| Product Kind | CNC turning, milling, drilling, grinding, wire EDM cutting and so on. |

| Our Solutions | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Producing,etc |

| Material | Aluminum,Brass,Stainless Metal,Copper,Plastic,Wooden,Silicone,Rubber,Or as for every the customers’ requirements |

| Surface Treatment method |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Sharpening,Laser Engraving |

| Dimension | As customers’ ask for |

| Service Venture | To offer manufacturing design and style, generation and complex services, mould development and processing, and so forth |

| Drawing Structure: | PRO/E, Auto CAD, Solid Functions,IGS,UG, CAD/CAM/CAE |

| Testing Equipment | Digital Peak Gauge, caliper, Coordinate measuring device, projection machine, roughness tester, hardness tester and so on |

| Industry employed | Machinery large obligation gear digital device Car spare areas optical telecommunication |

| Packing | Eco-helpful pp bag / EPE Foam /Carton containers or wooden boxes As customer’s specific needs |

| Trial sample time | 7-10 days following affirmation |

| Delivery time | 7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Services

OEM Areas

“EPG” model rotocultivator ploughshares in T.S. overall traces created in our factory have been analyzed and appraised by the Ministry of Agriculture and have acquired the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

Surface area Treatment method

Generation Procedure

Why Us

Best China manufacturer & factory factory in Acapulco de Juarez Mexico manufacturer for high quality custom cnc machining driving metal alloy steel gear shaft for bus With high quality best price

In this way, our products have continued to gain market acceptance and customers satisfaction over the past few years.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Heat treatment:

-

Quenching & Tempering, Carburizing & Quenching

- Surface Treatment:

-

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating

- Year:

-

2014-2016, 2014-2015, 2010-2016ear:

- Standard:

-

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Specification:

-

According to the the drawing

- Tolerance:

-

Based on drawing Length Dimension

- model:

-

CT660, X-BOW

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand.

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 PTO Shaft A PTO Adapter will be useful when operating Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could cause the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 point hitch.

>1000 Est. Time(days) 15 To be negotiated

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

high quality custom cnc machining driving metal alloy steel gear shaft for bus

(1). All kinds of gears, shaft, gear shaft, precision gear and CNC gear.

(2). Specialized in manufacturing all kinds of automobile transmission part based on drawings

(3). Material: ductile cast iron, carbon steel, alloy steel , stainless steel, , bronze/brass

(4). Modules: M1 to M8

(5). Meets ISO, DIN and ASTM standards

(6). Specification : According to the the drawing

|

Material |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Steel |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-1, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Control |

Outer Diameter |

Based on drawing |

|

Length Dimension |

Based on drawing |

|

|

Machining Process |

Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

|

|

Teeth Accuracy |

DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0 |

|

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc |

|

|

Heat Treatment |

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding |

|

|

Surface Treatment |

Blacking, Polishing, Anodization, ChroAccudrive Servo Gearheads Servo drives from EPG Drive benefit from the expertise and innovation of our more traditional brands. Available in both right angle and inline configurations, coupled with the availability of multiple precision levels, you are sure to find the right product for your application.EPG Drive Accudrive Servo Gearheadme Plating, Zinc Plating, Nickel Plating |

|

|

Standard |

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

PackagEPG brand rotocultivator ploughshares in T. line were selected as the Nationwide Rotary Tillage Machinery Industry “Perfect Brand Products” in 2007 by Rotocultivator Branch of China Agricultural Machinery Industry Association. ing & Shipping

CNC made in China – replacement parts – in Khamis Mushayt Saudi Arabia Machining and Hobbing Chain Wheel for Machine Parts with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 various branches. For a lot more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

one, creation engineering: Sand casting, die casting. Machining,forging,stamping, welding,injection molding,assembelyp

2,Materials: Aluminum,brass,stainless steel, carbon steel, grey iron,plastic ,rubber,

3, single method, high precision, small surface area roughness,

4, custom-made, we generate the elements in accordance to drawings or samples,

5, we will inspect the elements strictly and supply substance and inspection report.

Packing and Shipping

one. Standard: crate

2. Supply: As per agreement shipping on time

3. Shipping and delivery: As for every client ask for.

Our advantages

1.We can management the merchandise to fulfill your stringent requirement.

two. Different types of finish obtainable, like anodized, power coating, portray, sprucing, electrophoresis, plating. And many others.

three. Diverse proportions in accordance to the specifications

4. Can provide numerous measurements and packing according to distinct needs

5. We offer you the engineer session to your style for production improvement and co EPT preserving

Our Services:

1.Your inquiry connected to our products or prices will be replied in 24 hours.

two.Individual formula in accordance to customers’ special drawing requests.

three.Producer with big ability,makes certain the fa EPT manufacturing cycle soon after

confirming the purchase.

4.Security of sales region and personal data for all of our customers.

The use of original gear manufacturer’s (OEM) portion quantities or logos , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our company and the listed replacement elements contained herein are not sponsored, authorized, or made by the OEM.

Best China manufacturer & factory Custom metal cnc machining milling cnc machining camera parts With high quality best price

We have exported our products to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the USA, Canada, etc.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

-

Shear bolt torque limiter (SB) EPG GROUP offers high quality PTO shafts with tubes fixed by spring pin, cross joints with roller bearings with rollers

- OEM Service:

-

Support

- Tolerance:

-

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

Our unparalleled research and development expertise is also reflected in our solutions: from low-backlash planetary gearboxes through servo right-angle gearboxes and complete drive units to EPG ® 5, our fundamentally redesigned sizing software. More than a million of our units are in use around the world – for example in machine tools and production systems, food and packaging machines, wood processing machines, robotics, transportation, automation and handling technologies.

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

Custom metal cnc machining milling cnc machining camera parts

Product Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

| Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer’s specific requirements |

| Trial sample time | 7-10 days after confirmation |

| Delivery time | 7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Service

The company was certified by ISO9001:2008 Quality Management System.

The company was certified by ISO9001:2008 Quality Management System.

OEM Parts

Surface Treatment

Production Process

Why Us